4-axis vs. 5-axis dental milling machines: How to choose the most suitable milling machine

2025-02-27

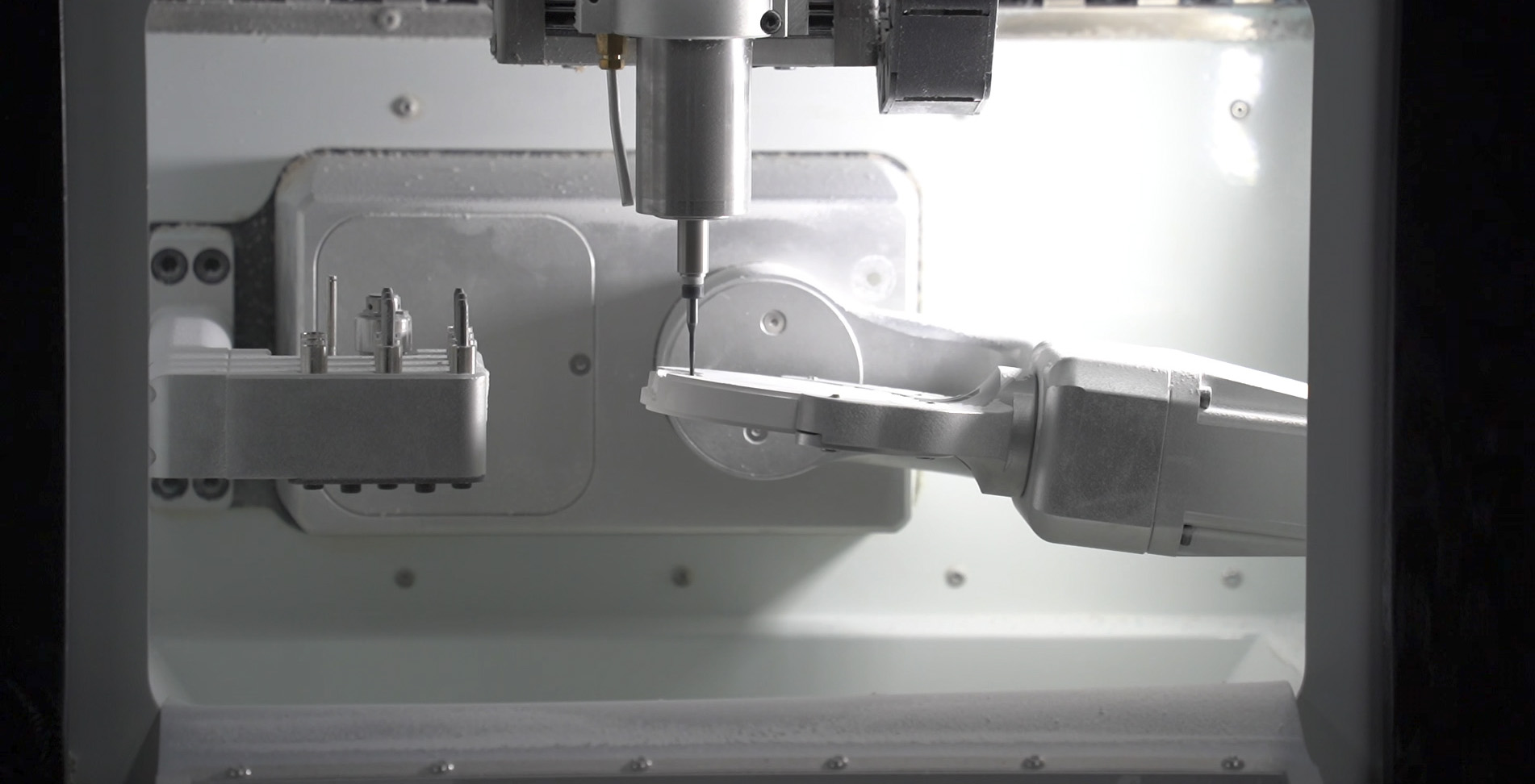

4-axis vs. 5-axis milling machines have always been a controversial topic in the selection of equipment for dental labs. Many believe that using a 4-axis milling machine may limit a lab's machining capabilities, but in fact, it is critical to choose the milling machine that best suits your needs. The following will provide a detailed comparison of these two milling machines to help you make an informed decision based on your lab's specific needs.

1. 4-Axis Dental Milling Machine

Number of axes of motion:

A 4-axis milling machine has three linear axes (X, Y, and Z) and one rotary axis (usually the A-axis) for workpiece rotation. This structure makes 4-axis milling machines suitable for most routine machining tasks.

Range of Machining:

Although a 4-axis milling machine can handle complex machining in three dimensions, with only one rotary axis it is less flexible when faced with complex shapes that require machining from multiple angles. For some simple restorations such as crowns and bridges, 4-axis milling machines are able to provide adequate machining capabilities.

Machining efficiency:

During machining, 4-axis milling machine may need to clamp the workpiece several times, and each clamping may lead to longer machining time and preparation time. While its precision and efficiency are perfectly adequate for simple restorations, longer machining cycles may be required for complex shapes.

Applicable Scenarios:

The 4-axis milling machine is suitable for the fabrication of routine restorations such as bridges, crowns and inlays. If the laboratory's main business is focused on these standardized restorations, the 4-axis milling machine will be a cost-effective choice.

2. 5-axis dental milling machine

Number of axes of motion:

The 5-axis milling machine has three linear axes (X, Y, Z) and two rotary axes (A and B) for workpiece and tool rotation respectively. With the two extra rotary axes, the 5-axis milling machine is able to handle more complex geometries. Range of machining:

Range of machining:

The 5-axis milling machine is capable of more complex 5D machining, and it can machine multiple faces in a single clamping, reducing the need for multiple clamping of the workpiece. This allows 5-axis milling machines to achieve more complex shapes, angles, and finer details, and is especially superior for customized restorations.

Machining Efficiency:

Because the 5-axis milling machine is able to accomplish more machining in a single clamping, it provides much higher machining efficiency and accuracy, reducing the number of clamping passes and thus shortening the production cycle. In addition, due to its efficient machining, the 5-axis milling machine is able to handle complex restorations with greater precision and shorter machining times.

Applicable scenarios:

The 5-axis milling machine is ideally suited for the processing of complex, high-precision restorations, such as personalized implant abutments, implant bridges and complex all-ceramic crowns. For tasks requiring multi-angle machining and fine adjustment, 5-axis milling machines are undoubtedly the better choice.

3. Key factors for selection

Flexibility and machining capability:

5-axis milling machines offer more machining flexibility due to their two rotary axes, which are able to handle multiple machining surfaces at the same time without the need for multiple clamping. This allows 5-axis milling machines to handle more complex and delicate restorations.

Cost and Efficiency:

5-axis milling machines are more expensive and complicated to operate, making them suitable for dental laboratories that require high precision and complex designs. The 4-axis milling machine is more cost-effective and suitable for laboratories with limited budgets, especially those laboratories that are primarily involved in the production of standard restorations.

Laboratory needs:

If your laboratory mainly produces simple restorations, such as single crowns or bridges, then a 4-axis milling machine is sufficient and more affordable. If you are planning to expand your business to involve more complex, personalized restorations such as implant abutments, complex bridges, etc., then a 5-axis milling machine will give your lab greater machining power and flexibility.

4. Conclusion

The choice between a 4-axis or a 5-axis milling machine ultimately depends on your lab's specific needs and future growth plans:

4-axis milling machine: suitable for processing routine restorations such as crowns and bridges, simple to operate, cost-effective and suitable for common tasks that do not require multi-angle machining.

5-axis milling machine: suitable for handling complex restorations such as customized implant abutments and precision implant bridges. Although more expensive, they offer greater flexibility and efficient machining capabilities for dental laboratories with higher demands.

Whether you choose a 4-axis or 5-axis milling machine, make a choice that takes into account your lab's type of business, budget, and machining precision needs to ensure that the equipment you choose will support your production needs over the long term.