Application of CAD/CAM Machines in Dentistry

2024-12-13

Application of CAD/CAM Machines in Dentistry

Introduction

CAD/CAM (Computer-Aided Design and Computer-Aided Manufacturing) technology has developed rapidly in the field of dentistry and has become an important part of modern dental restoration technology. This article will explore the application and advantages of CAD/CAM machines in the field of dentistry.

Background

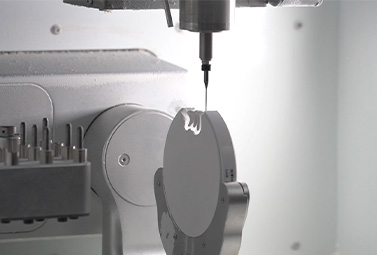

CAD/CAM technology was originally used in the manufacturing industry and was introduced to dentistry in the 1980s. It improves the accuracy and efficiency of dental restorations through digital workflows. The CAD (Computer-Aided Design) part involves using scanners and software to create digital models of teeth, while the CAM (Computer-Aided Manufacturing) part uses these digital designs to make dental restorations such as crowns, bridges, and inlets.

Types of CAD/CAM Machines

Chairside System

Features: The chairside system integrates scanning, design and manufacturing functions, allowing dentists to complete restorations in one visit.

Popular Brands: CEREC (Dentsply Sirona), Planmeca Fit.

Features: Single-day visit, same-day completion, can significantly reduce the number of patient visits, thereby improving the comfort and efficiency of treatment.

Laboratory system

Features: Laboratory systems are mainly used in dental laboratories to promote high precision in dental laboratories.

Popular brands: Roland DWX series, Amann Girrbach Ceramill.

Advantages: Can handle more complex restoration designs, can be mass-produced, and provide production capacity.

Main advantages

Consistency

CAD/CAM technology provides high precision through digital design and manufacturing, reducing the errors of traditional manual milling. It is that each restoration can be precisely matched to achieve seamless fit.

Time efficiency

The chairside system can complete the restoration in one visit, reducing the patient's waiting time and the number of visits. The laboratory system can mass-produce restorations and improve overall efficiency.

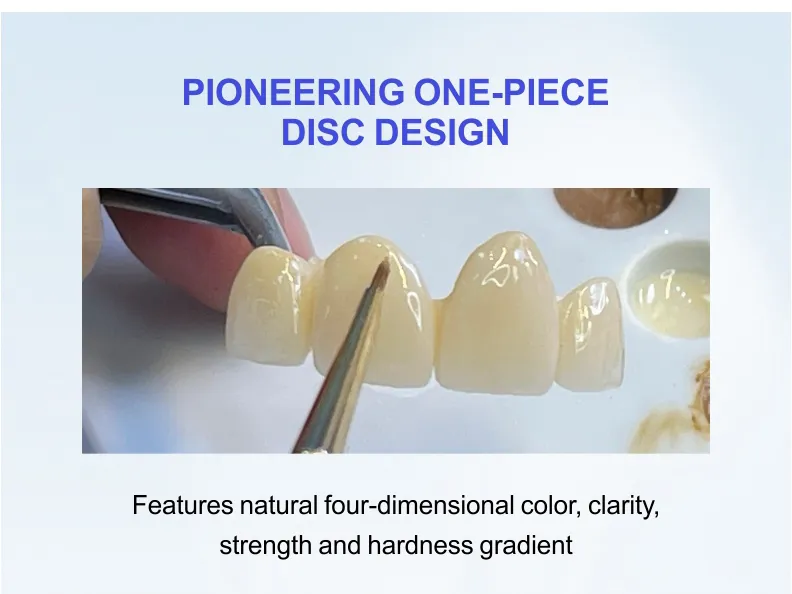

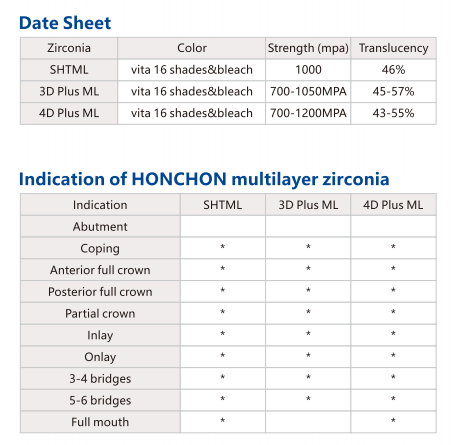

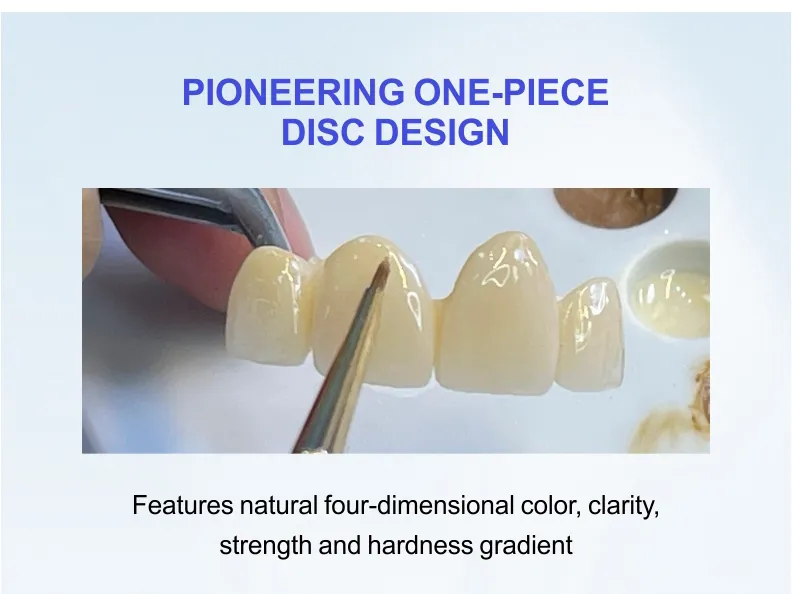

Material diversity

CAD/CAM technology can be used with a variety of materials, including oxide, ceramics, resins, and metal alloys. This material versatility enables dentists to provide personalized restoration solutions based on the patient's needs and matching the patient's budget.

Digital workflow

The entire process from scanning, design to manufacturing is digital. It improves work efficiency, facilitates recording and communication, and reduces errors.

Clinical Applications

Single Crown

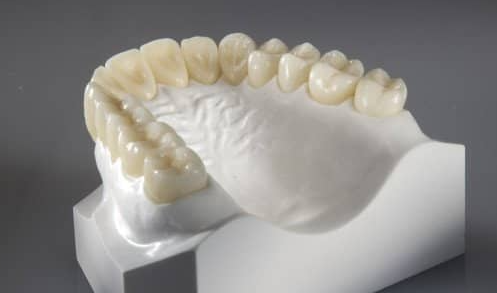

With a chairside CAD/CAM system, dentists can complete single crown restorations in a single visit. Intraoral scanners can capture digital impressions, and the final design software is used to make crowns, and chairside milling machines make restorations.

Complex full-mouth restorations

For restorations, such as full-mouth crowns or bridges, laboratory systems provide higher manufacturing accuracy and material selection. Digital impressions can be transmitted remotely to dental laboratories, where technicians design and manufacture restorations.

Future Trends

Artificial Intelligence and Machine Learning

Artificial Intelligence will further enhance the development of CAD/CAM technology, and in the future, it will be possible to automate the design process and optimize manufacturing throughout the process.

3D Printing Technology

3D printing is developing rapidly and will soon be combined with CAD/CAM technology to provide patients with more complex and customized dental restoration solutions.

Cloud Data Storage

Cloud technology introduces easy access and sharing of digital impressions and data designs, thereby improving collaboration efficiency and data security.

References

Patterson Dental: CAD/CAM Milling Machines

CEREC CAD/CAM Systems | Dentsply Sirona USA

CAD/CAM Dental: What is it and how does it work?

CAD/CAM Solutions for Dentists: Explore Now | Dentsply Sirona

CAD/CAM | Milling Machines | Milling Machines DWX Series | DGSHAPE, Roland DG