Product Description

The Amann Girrbach CAD CAM Dental Milling Bur by Changsha Honchon Technology Co., Ltd. is a premium milling tool designed for precision and durability. Manufactured with the finest quality carbide and coated with advanced materials, these burs are engineered to deliver exceptional performance in dental milling applications. They are compatible with Amann Girrbach milling systems and offer a range of features, including:

Superior Cutting Efficiency

The Amann Girrbach CAD CAM Dental Milling Burs from Changsha Honchon Technology Co., Ltd. are the epitome of cutting efficiency, designed to maximize productivity in dental labs. The burs' superior cutting power is a result of a combination of advanced geometries, premium carbide materials, and specialized coatings that reduce friction and increase cutting speed. This efficiency is crucial when working with tough dental materials, as it minimizes the risk of chipping or cracking while also reducing the time required for each milling operation.

The design of the burs is focused on optimizing the cutting action for various dental applications. With sharp edges that maintain their integrity through multiple uses, the burs cut cleanly through materials, leaving a smooth finish that requires minimal post-milling processing. This efficiency is not only a testament to the burs' quality but also to the meticulous engineering that goes into their production. The burs are rigorously tested to ensure that they perform consistently at high speeds, providing dental technicians with the confidence that they can rely on these tools for rapid and precise material removal.

Long Service Life

Longevity is a hallmark of the Amann Girrbach CAD CAM Dental Milling Burs, and it is a direct reflection of the high standards upheld by Changsha Honchon Technology Co., Ltd. Our burs are designed to endure the rigors of dental milling, which often involves working with hard materials for extended periods. The robust construction of the burs, coupled with the use of wear-resistant carbide, ensures that they retain their cutting effectiveness over many uses.

The service life of our milling burs is further extended by the application of specialized coatings. These coatings are engineered to withstand high temperatures and resist abrasion, which are common challenges in milling operations. The result is a bur that not only lasts longer but also maintains its precision throughout its lifespan. This durability translates into cost savings for dental labs, as the need for frequent replacements is significantly reduced, and the overall cost per restoration is lowered.

High Precision and Consistency

Precision and consistency are the cornerstones of quality dental restorations, and the Amann Girrbach CAD CAM Dental Milling Burs deliver on both fronts. Each bur is manufactured with exacting tolerances to ensure that it produces consistent results every time it is used. The precise dimensions of the burs allow for accurate material removal, which is critical for achieving the fine detail required in dental prosthetics.

The burs are also designed to work seamlessly with CAD CAM systems, translating digital designs into physical restorations with high fidelity. The consistency in performance ensures that whether a technician is working on a single-unit crown or a full-arch bridge, the results are reliably accurate. This level of precision not only satisfies the aesthetic and functional requirements of dental restorations but also contributes to the fit and comfort for the patient.

Compatibility with a Wide Range of Dental Materials

The versatility of the Amann Girrbach CAD CAM Dental Milling Burs is evident in their compatibility with a diverse array of dental materials. Changsha Honchon Technology Co., Ltd. understands the evolving landscape of dental materials, from traditional metals to modern ceramics and polymers. Our milling burs are designed to tackle materials such as zirconia, lithium disilicate, PEEK, PMMA, and various alloys with ease.

This compatibility is crucial for dental labs that aim to be full-service providers, capable of fabricating restorations from any material prescribed by the dentist. The burs' ability to adapt to different materials without compromising performance allows labs to streamline their operations, as they can rely on a single set of tools for a wide range of milling tasks. Additionally, this flexibility empowers dental technicians to experiment with new materials and techniques, fostering innovation in dental restoration.

Availability in Various Sizes and Shapes for Different Milling Needs

Changsha Honchon Technology Co., Ltd. offers the Amann Girrbach CAD CAM Dental Milling Burs in a comprehensive range of sizes and shapes to address the diverse milling needs of dental labs. The variety of burs available ensures that technicians can select the optimal tool for each specific task, whether it involves bulk material removal or intricate detail work. The availability of different burs is critical for achieving the desired outcomes in dental restoratio

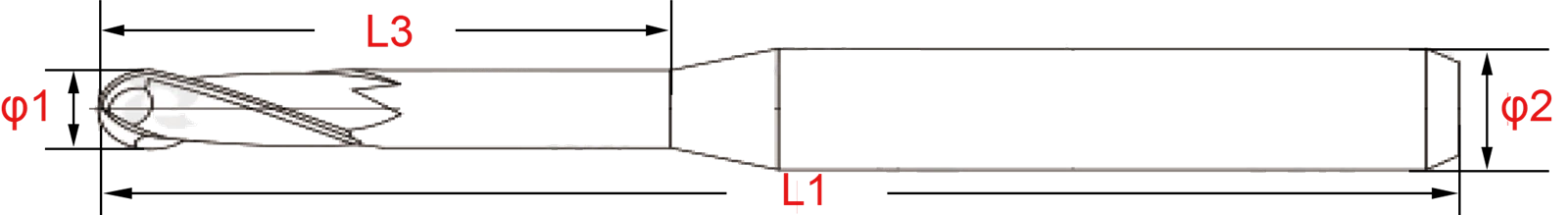

Amann Girrbach CAD CAM Dental Milling Bur Available sizes

| Amann girrbach milling burs for Milling Zirconia | |||

| |||

| headmeter φ1 (mm) | Total Length L1 (mm) | Shaft φ2 (mm) | Type |

| 0.3 | 47 | 3 | DLC/RC/DC |

| 0.6 | 47 | 3 | DLC/RC/DC |

| 1.0 | 47 | 3 | DLC/RC/DC |

| 2.0 | 47 | 3 | DLC/RC/DC |

| 2.5 | 47 | 3 | DLC/RC/DC |

| Amann girrbach milling burs for Milling EMAX | |||

| |||

| headmeter φ1 (mm) | Total Length L1 (mm) | Shaft φ2 (mm) | Type |

| 0.4 | 47 | 3 | DC |

| 1.0 | 47 | 3 | DC |

| 1.4 | 47 | 3 | DC |

| 1.8 | 47 | 3 | DC |

| Amann girrbach milling burs for Milling PMMA | |||

| |||

| headmeter φ1 (mm) | Total Length L1 (mm) | Shaft φ2 (mm) | Type |

| 0.3 | 47 | 3 | / |

| 0.6 | 47 | 3 | / |

| 1.0 | 47 | 3 | / |

| 2.0 | 47 | 3 | / |

| 2.5 | 47 | 3 | / |

Contact Us

For more information, to place an order, or to inquire about our full range of products and services, please contact Changsha Honchon Technology Co., Ltd. at +8613055185196 ,lidya@honchon.com Our dedicated customer service team is ready to assist you with any questions or needs you may have.

.jpg)