What Are Pre-sintered Zirconia Milling Burs?

Pre-sintered Zirconia Milling Burs are precision tools designed to mill zirconia in its pre-sintered state. They provide smooth and efficient cutting, ensuring consistent results for dental restorations such as crowns, bridges, and implants.

Key Features of Zirconia Milling Burs

Durable Coating: Available in DC, DLC, and RC coatings for extended tool life.

Precision Cutting: Delivers smooth milling surfaces with minimal chipping or cracking.

Universal Compatibility: Supports a variety of milling systems such as Roland, VHF, and Amann Girrbach.

High Efficiency: Optimized for fast and effective milling in the pre-sintered state.

Types of Zirconia Milling Burs

By Coating: DC (Diamond Coating), DLC (Diamond-Like Coating), and RC (Resin Coating).

By Machine Compatibility: Roland, VHF, Amann Girrbach, and other open or closed systems.

Material Composition

Title: Materials of Zirconia Milling Burs

Our burs are crafted from premium carbide base materials and enhanced with cutting-edge coating technologies such as DLC (Diamond-Like Coating), ensuring superior wear resistance and consistent cutting performance.

Applications of Zirconia Milling Burs

Crown and Bridge Milling: Accurate and efficient processing of dental restorations.

Implant Prosthetics: Ideal for complex implant-supported restorations.

Dental Laboratories: Designed for high-volume production needs.

Manufacturing Process

How We Manufacture Zirconia Milling Burs

Material Selection: Premium carbide materials are sourced to ensure strength and durability.

Coating Application: Advanced coatings (DC, DLC, RC) are applied for wear resistance.

Precision Manufacturing: CNC machining ensures accuracy and consistency.

Quality Inspection: Each bur undergoes rigorous testing to meet international standards.

How to Maintain Zirconia Milling Burs

Post-use Cleaning: Remove debris to preserve the coating and cutting edges.

Proper Storage: Keep in a dry, dust-free environment to prevent damage.

Recommended Usage: Operate at specified speeds and pressures for optimal performance.

Partner with HONCHON

Submit Your Inquiry: Share your specifications and quantity requirements.

Confirm Order Details: Approve design, coating options, and pricing.

Manufacturing: Production begins upon confirmation.

Shipping: Products are delivered promptly via our global logistics network.

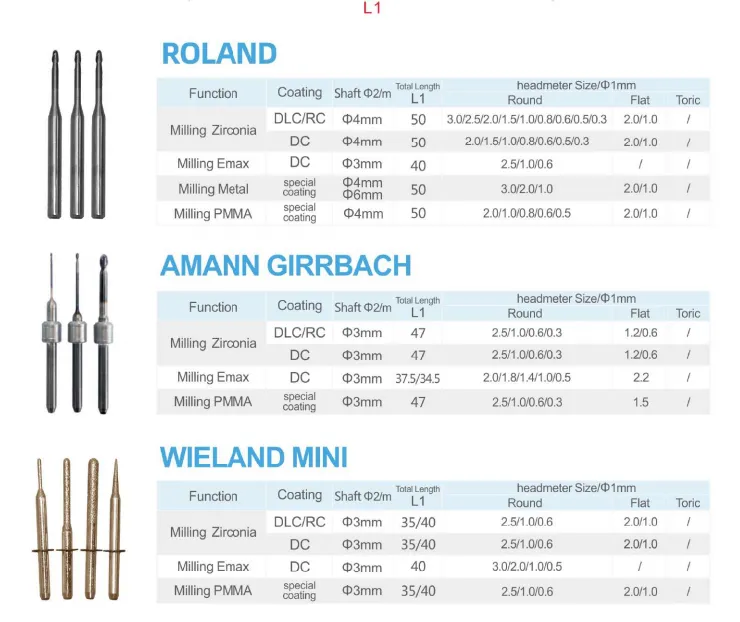

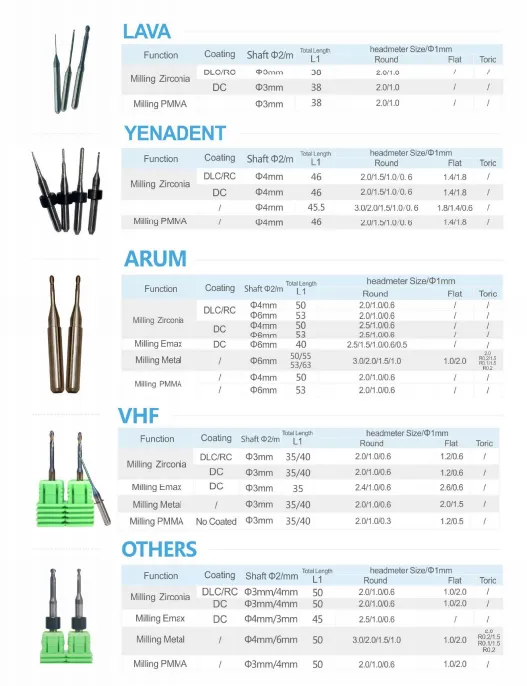

Product Specifications

Our Certifications

ISO 13485

CE

FDA

Success Stories

Collaborations with leading dental labs in Europe, providing high-quality milling tools for large-scale production.

HONCHON: Your Trusted Partner for Precision Milling Tools

HONCHON is a globally recognized manufacturer specializing in high-precision and durable milling tools for the dental industry. With an 8,000-square-meter advanced facility and internationally certified production systems (ISO 13485, CE, FDA), our products are trusted by dental labs in over 120 countries, including markets in Europe, the Americas, and Asia.

Our Advantages

Premium Materials: Made from high-grade carbide base materials with advanced coating technology to ensure durability and precision.

Expert Design: Specifically engineered to be compatible with a wide range of dental milling machines.

Technical Support: Comprehensive training and professional assistance to support your operations.

Custom Solutions: Flexible OEM/ODM services to meet unique customer requirements.

Fast Delivery: Standard products shipped within 1-3 business days.

Global Reach: Efficient international logistics covering major global markets.

Frequently Asked Questions

What coating options are available for zirconia milling burs?

We offer DC, DLC, and RC coatings tailored for different milling needs.

Are these milling burs compatible with my machine?

Yes, our burs are compatible with popular systems like Roland, VHF, and Amann Girrbach.

What is the delivery time for an order?

Standard products are shipped within 1-3 business days.

.jpg)