Arum Metal Milling Burs: Precise and Efficient Milling Solution

| CADCAM System | Function | Coating | Shaft Φ2/mm | Total Length L1/mm | headmeter Size/Φ1mm | ||

| Round | Flat | Toric | |||||

| Arum | Milling Zirconia | DLC/RC/DC | Φ4mm | 50 | 2.0/1.0/0.6/0.3 | / | / |

| DLC/RC/DC | Φ6mm | 53/63 | 2.0/1.0/0.6/0.3 | / | / | ||

Miling Emax | DC | Φ6 | 50 | 2.5/1.5/1.0/0.6/0.5 | / | / | |

| Φ4 | 45 | 2.5/1.5/1.0/0.6 | / | / | |||

Miling Metal | / | Φ6mm | 50 | 3.0/2.0/1.0/1.5/0.6 | 1.0/2.0 | 2.0 R0.2/ 1.5R0.2 | |

| / | Φ4mm | 50 | 3.0/2.0/1.0/1.5 | / | / | ||

Milling PMMA | / | Φ4mm | 50 | 2.0/1.0/0.6/0.3 | / | / | |

| / | Φ6mm | 53/63 | 2.0/1.0/0.6/0.3 | / | / | ||

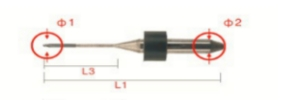

| Shank Diameter | 6.0mm/4mm |

| Flute Diameter | 1.0mm,1.5mm,2.0mm,3.0mm |

| Overall Length | 50mm |

| Used | For cutting Metal |

| Coating | ALNOVA Coating |

| Fit for | Arum Machine |

| Application | For Dental Laboratory |

| Package | Plastic Tube/Plastic Box |

| Advantage | high quality raw material, 10+ years' manufacturer experience |

| Service | OEM&ODM |

Advantages of our factory:

Denture Tools –Our dental laboratory tools contain dental burs, pindex drills, milling tools and CAD/CAM end mills. They are all made from high quality tungsten carbide with precise tolerance in conformity with ISO standards. We also produce zirconia ceramic dental burs, which are most suitable for trimming acrylic, resin, plaster, etc.

CAD/CAM End Mills – Our solid carbide end mills, compatible with mainstream CAD/CAM machines or systems, are good choice for trimming zirconia porcelain, titanium, cobalt-chromium alloy, PMMA, etc. Depending on trimmed material, we recommend different coating. While DC coating are for trimming zirconia, TiAlN coating is targeted at metals, and CrN coating is especially suitable for PMMA.

Nail Drill Bits - Our nail drill bits are known for having consistent quality and high wear resistance with professional production accuracy. Able to work in conjunction with a variety of e-files, our drill bits are crafted to have a greater grinding efficiency, making them an ideal choice for use in high-production jobs.

Arum metal milling Burs Advantages :

Compatible Arum Arum Metal Milling Burs is a state-of-the-art milling solution that ensures precise and efficient milling of metal materials. The product is designed with cutting edge technology and quality materials that guarantee consistent, high-quality results.

One of the most significant advantages of the Compatible Arum Arum Metal Milling Burs is its excellent efficiency. The burs are equipped with high-speed blades that allow for faster and precise milling, reducing production time and increasing output. Additionally, the burs' compatibility with multiple milling machines makes it easy for users to integrate them into their current workflow.

Another benefit of using Compatible Arum Arum Metal Milling Burs is their durability. The burs are made with high-quality materials that can withstand heavy use without breaking or wearing out easily. This ensures that the burs maintain their high-performance standards for an extended period, thus reducing the need for frequent replacements and maintenance.

Compatible Arum Arum Metal Milling Burs is suitable for a wide range of applications. Still, it is particularly useful for dental and medical professionals involved in the manufacturing of dental prostheses, implants, and medical instruments. The burs mill titanium, cobalt chrome, and other metal materials used in the production of these medical devices with precision and efficiency.

To use Compatible Arum Arum Metal Milling Burs, users will require an Arum milling unit and a compatible CAM design software. The unit's milling parameters should be accurately calibrated to ensure optimal performance. Also, users should follow the manufacturer's guidelines regarding maintenance and cleaning to prolong the product's lifespan.

In summary, Compatible Arum Arum Metal Milling Burs is an excellent milling solution that offers precision, efficiency, and durability. It is a reliable tool for dental and medical professionals involved in the production of medical devices and prostheses. With proper use and maintenance, its users can enjoy high-quality results and increased productivity.

FAQ

Q1: Are you a manufacturer ?

Yes, we are one of the leader and professional manufacturer in China.

Q2: Are there differences among zirconia ceramics ?

Difference among zirconia ceramic can occur with the level of purity of zirconia, grain size, trace elements and stabilizing compounds, and consistency of formulation.

Difference can exist in shrinkage from batch to batch because of differences in the thermal expansion(CTE).

Q3: Can I get your price list ?

Yes, sure, we will be quite glad to send you our price list after knowing your requirment in details.

Q4: Can I print our own logo or design on the products ?

We accept OEM or ODM, we can print your own logo/brand according to your requirement.

Q5: Which payment are acceptbale ?

We acacept Paypal, Bank transfer, Western Union etc.

.jpg)