Product Introduction

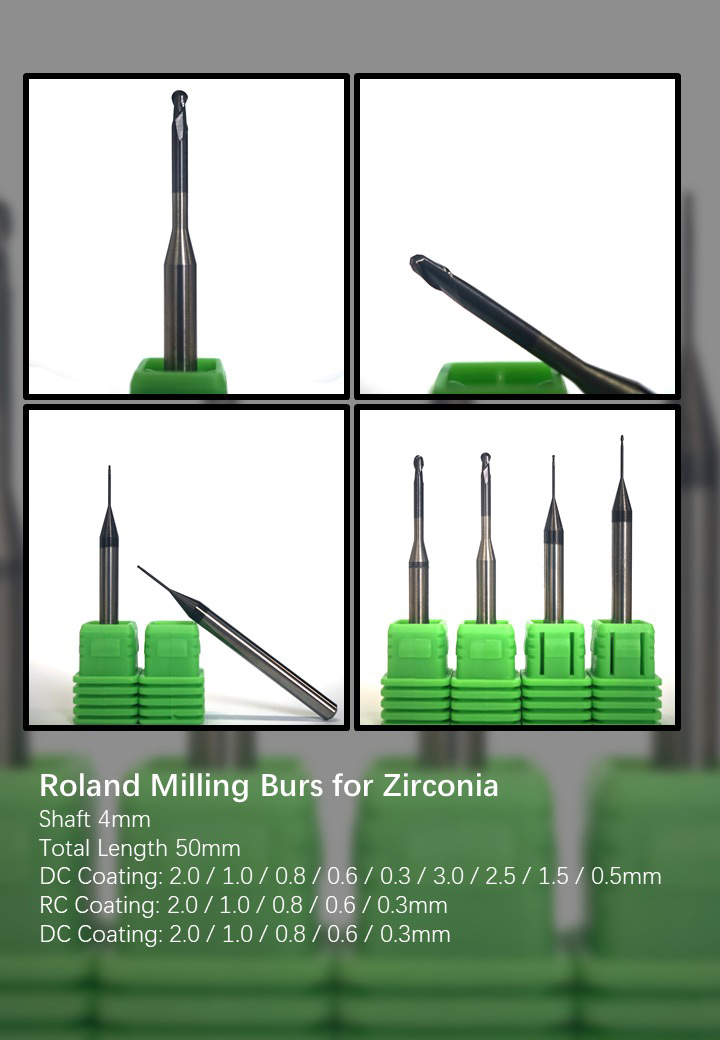

Roland Diamond Coated Milling Burs manufactured by Changsha Honchon Technology Co., Ltd. are renowned for their high quality and exceptional performance in dental milling applications.These milling burs are crafted using advanced techniques and premium materials, catering to various cutting through zirconia, PMMA, metals, and EMAX. Through continuous innovation and refinement, our products have become a preferred choice in the dental industry, earning the trust and recognition of numerous customers worldwide.

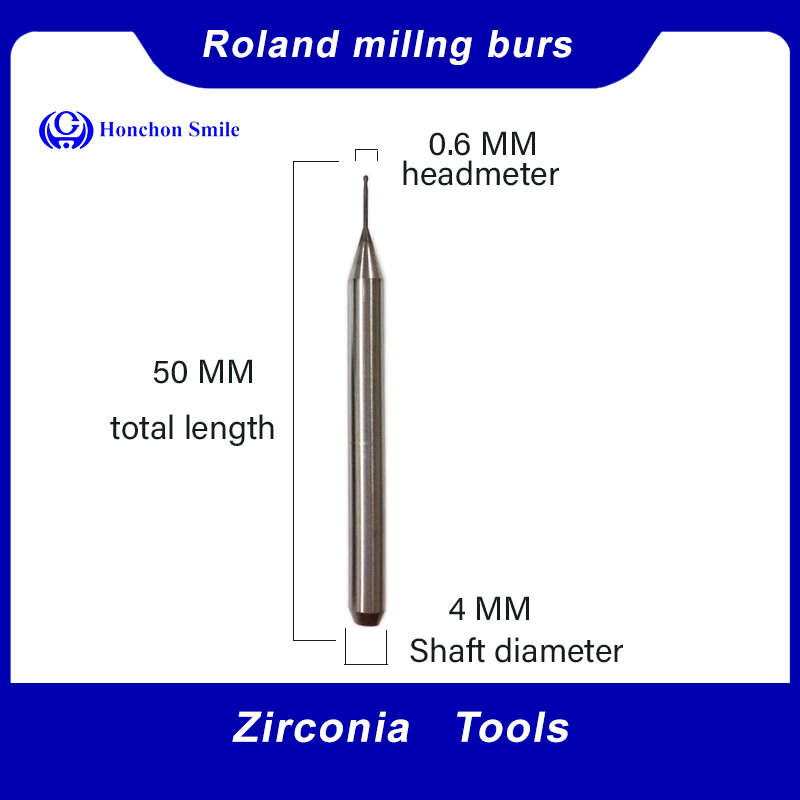

Product Specifications

Coating Types: Diamond Coated (DC), Resin Coated (RC), Diamond-Like Carbon (DLC)

Milling Functions: Zirconia, PMMA, Metals, EMAX

Specifications: Customizable according to customer requirements

Production Process: Advanced manufacturing processes ensuring precision and stability

Production Volume: Exceeds 100,00 units per month

Lead Time: 2-4 days

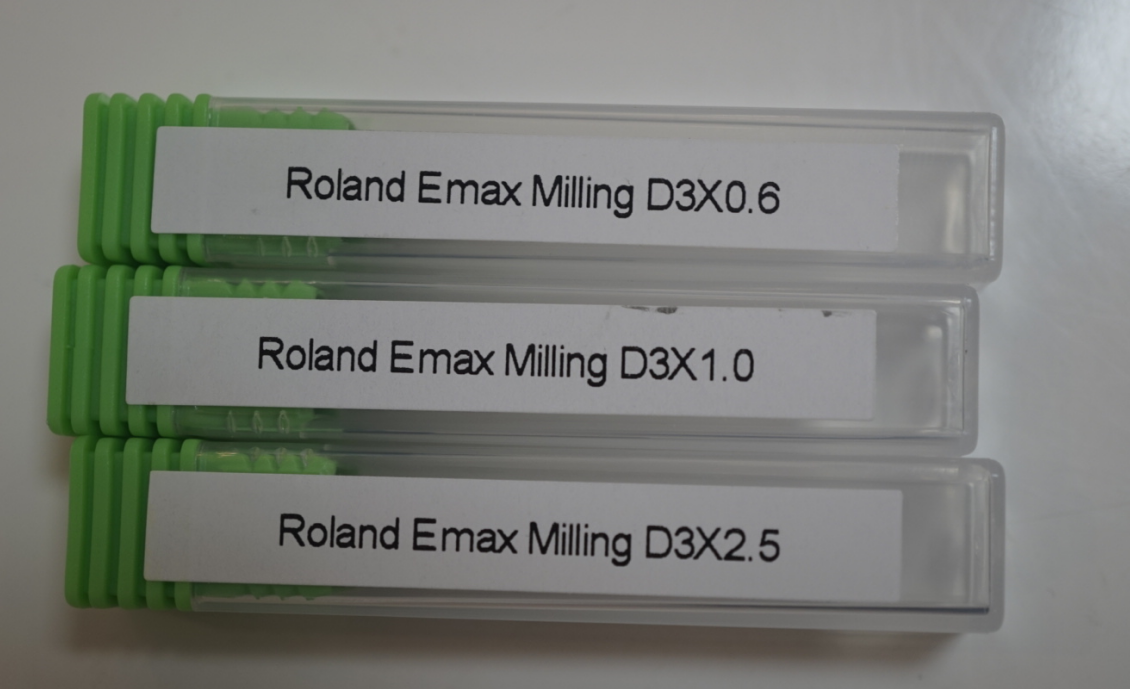

Packaging: Customizable packaging ensuring secure transit

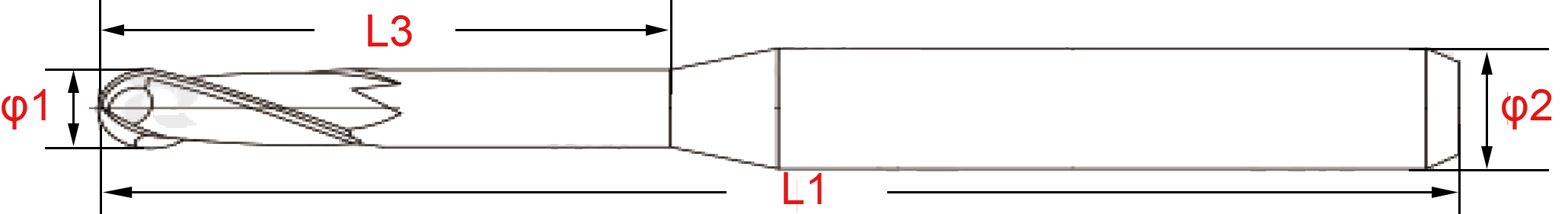

| Roland Milling Bur for Milling Zirconia size | |||

| |||

| headmeter φ1 (mm) | Total Length L1 (mm) | Shaft φ2 (mm) | Type |

| 0.3 | 50 | 4 | DLC/RC/DC |

| 0.5 | 50 | 4 | DLC/RC/DC |

| 0.6 | 50 | 4 | DLC/RC/DC |

| 0.8 | 50 | 4 | DLC/RC/DC |

| 1.0 | 50 | 4 | DLC/RC/DC |

| 1.5 | 50 | 4 | DLC/RC/DC |

| 2.0 | 50 | 4 | DLC/RC/DC |

| 2.5 | 50 | 4 | DLC/RC/DC |

| 3.0 | 50 | 4 | DLC/RC/DC |

| Roland Milling Bur for Milling EMAX size | |||

| |||

| headmeter φ1 (mm) | L1 (mm) | Shaft φ2 (mm) | Type |

| 0.5 | 40 | 3 | DC |

| 1.0 | 40 | 3 | DC |

| 1.5 | 40 | 3 | DC |

| 2.0 | 40 | 3 | DC |

| 3.0 | 40 | 3 | DC |

| Roland Milling Bur for Milling Metal size | ||||

| ||||

| headmeter φ1 (mm) | L3 (mm) | L1 (mm) | Shaft φ2 (mm) | Type |

| 0.6 | 6 | 50 | 3 | / |

| 1.0 | 12 | 50 | 3 | / |

| 2.0 | 18 | 50 | 3 | / |

| 3.0 | 18 | 50 | 3 | / |

| Roland Milling Bur for Milling PMMA size | |||

| |||

| headmeter φ1 (mm) | Total Length L1 (mm) | Shaft φ2 (mm) | Type |

| 0.3 | 50 | 4 | / |

| 0.5 | 50 | 4 | / |

| 0.6 | 50 | 4 | / |

| 0.8 | 50 | 4 | / |

| 1.0 | 50 | 4 | / |

| 1.5 | 50 | 4 | / |

| 2.0 | 50 | 4 | / |

| 2.5 | 50 | 4 | / |

| 3.0 | 50 | 4 | / |

Product Features

Premium Materials: Our milling burs are crafted using high-grade materials to ensure durability and stability.

Multiple Coating Options: Customers can choose from DC, RC, or DLC coatings to meet the specific milling requirements of different materials.

Precision Cutting: Designed and manufactured with precision engineering, our burs enable high-precision cutting, ensuring quality dental restorations.

High Efficiency Production: Our milling burs enable high-speed milling, enhancing production efficiency and reducing lead times.

Customer Satisfaction: With a customer repurchase rate of up to 90%, our products demonstrate outstanding performance and value for money.

Production Process

Our manufacturing process for Roland Diamond Coated Milling Burs involves several meticulous steps to ensure precision and quality:

Material Selection: We begin by carefully selecting high-quality materials that are suitable for dental milling applications, ensuring durability and performance.

Design and Engineering: Our experienced team of engineers designs the burs with precision, taking into account factors such as cutting efficiency, durability, and compatibility with Roland machines.

Machining: The selected materials are then subjected to advanced machining processes, including CNC milling and grinding, to achieve the desired shape and dimensions with utmost accuracy.

Coating Application: Depending on the specific requirements, the burs undergo coating application using state-of-the-art techniques. We offer a variety of coatings such as Diamond Coated (DC), Resin Coated (RC), and Diamond-Like Carbon (DLC) to suit different milling needs.

Quality Control: Throughout the production process, rigorous quality control measures are implemented to ensure that each milling bur meets our stringent standards for performance and reliability.

Superior Product Quality

Our commitment to delivering high-quality products is backed by:

Sufficient Production Experience: With over a decade of manufacturing and operational experience, we have honed our expertise in producing top-notch dental milling burs.

Continuous Iteration and Improvement: We constantly iterate and improve our products based on customer feedback, technological advancements, and industry trends. This dedication to innovation ensures that our products remain at the forefront of the market.

Refined Manufacturing Processes: We continuously refine our manufacturing processes to optimize efficiency, minimize defects, and enhance product consistency. This results in milling burs that consistently meet or exceed customer expectations.

Customer Repurchase Rate

Customers keep coming back for our products due to:

Exceptional Product Quality: Our milling burs consistently deliver superior performance, precision, and durability, earning the trust and loyalty of customers worldwide.

Excellent Service: We prioritize customer satisfaction and strive to provide exceptional service at every stage of the purchasing process. Our responsive support team is always available to address any inquiries or concerns promptly.

Fast Shipping: We understand the importance of timely delivery, which is why we ensure fast turnaround times for order processing and shipping. Customers appreciate our promptness in fulfilling their orders, contributing to a positive buying experience.

Seamless Integration with Roland Machines

Our milling burs are meticulously engineered to seamlessly integrate with Roland machines, offering:

Optimized Compatibility: The design and specifications of our burs are tailored to perfectly complement Roland milling machines, ensuring smooth operation and optimal performance.Precision Machining: Our burs enable precise and efficient milling, allowing Roland machines to achieve exceptional results in dental prosthetics fabrication.

Reliable Performance: Customers can rely on the consistent performance and compatibility of our milling burs with Roland machines, streamlining their workflow and enhancing productivity.

Packaging and Shipping

We offer flexible packaging solutions tailored to meet customer requirements, ensuring the safe transit of our products. With a short lead time of 2-4 days, we strive to ensure prompt delivery, enabling customers to receive their orders in a timely manner.

Company Services

Changsha Honchon Technology Co., Ltd. boasts over 10 years of manufacturing experience, dedicated to providing customers with high-quality products and services. We offer diverse payment options to accommodate varying customer preferences. Our highly professional team is responsive to customer needs, providing expert technical support and after-sales service to ensure a satisfying shopping experience for our customers.

Conclusion

Roland Diamond Coated Milling Burs from Changsha Honchon Technology Co., Ltd. are the ideal choice for your dental fabrication needs. We are committed to delivering high-quality, high-performance products while offering excellent customer service, fostering mutual growth with our customers.

.jpg)