1.Product Introduction:

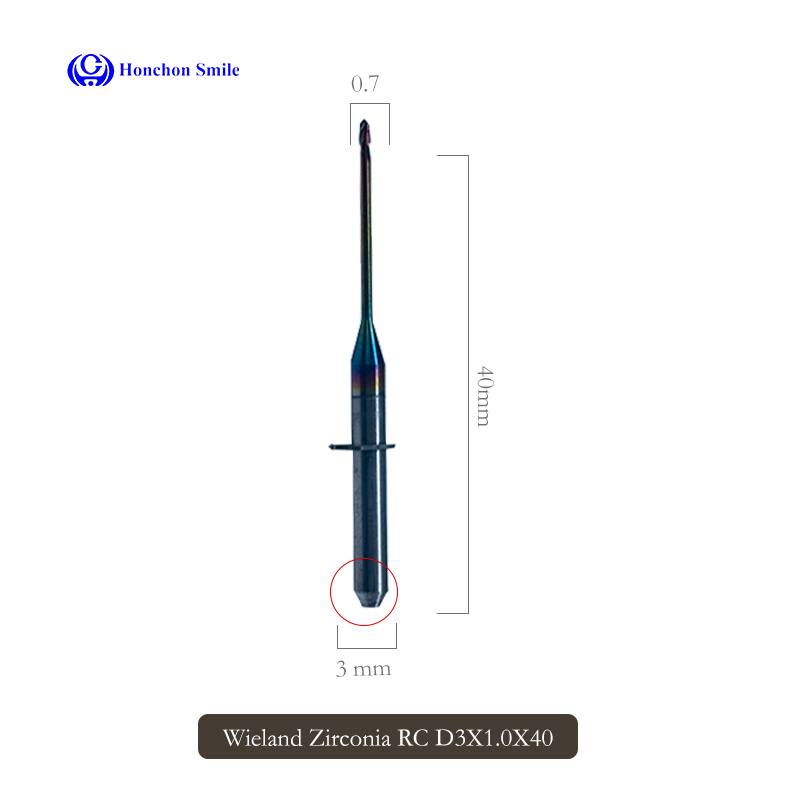

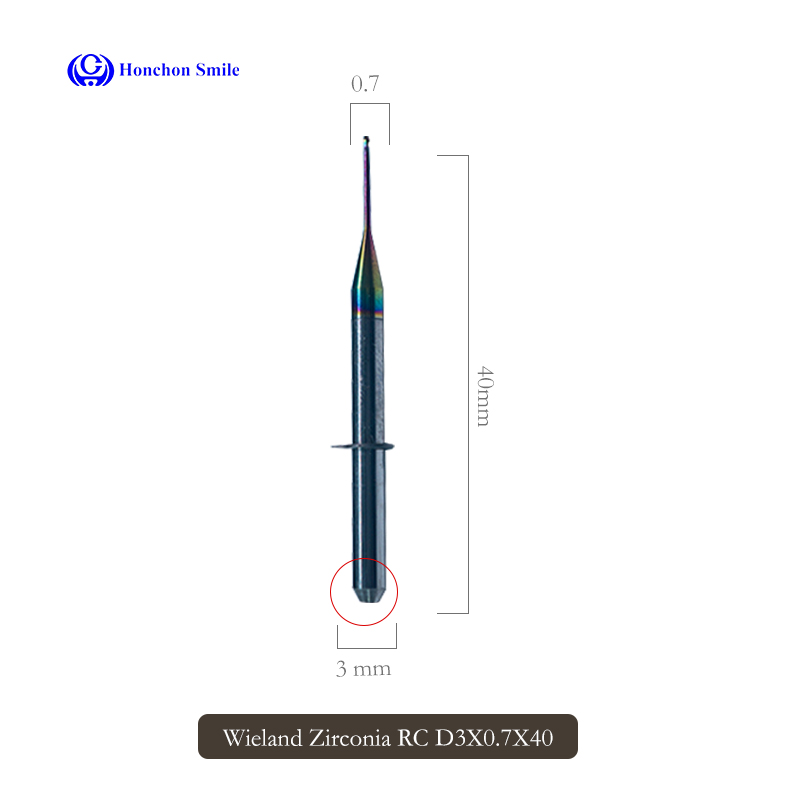

The Wieland Mini Milling Burs, produced by Changsha Honchon Technology Co., Ltd., are specifically designed to be compatible with Wieland machines. These burs come in three different types of coatings, namely DC, RC, and DLC, and are available in various sizes and lengths. They can efficiently mill three types of dental prosthetic materials: zirconia, PMMA, and EMAX.

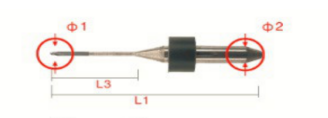

2.Product Parameter (Specification):

Coating Types: DC, RC, DLC

Compatibility: Wieland machines

Available Sizes: 0.3/0.5/0.6/0.7/1.0/2.0/2.5/3.0

Length: 35/40

Dental Prosthetic Materials: Zirconia, PMMA, EMAX

| ||||||

| CADCAM System | Function | Coating | Shaft 2/mm | Total Length L1/mm | headmeter Size/1mm | |

| Round | Flat | |||||

| wieland mini | Milling Zirconia | DLC | 3mm | 35/40 | 2.5/1.0/0.6/0.3 | 1.2/0.6/2.0/1.0 |

| RC | 3mm | 35/40 | 2.5/1.0/0.6/0.3 | / | ||

| DC | 3mm | 35/40 | 2.5/1.0/0.7/0.3 | / | ||

| Milling Emax | DC | 3mm | 40 | 3.0/2.0/1.0/0.5 | / | |

| Miling PMMA | / | 3mm | 35/40 | 2.5/1.0/0.6/0.3 | 1.2/0.6/2.0/1.0 | |

3.Product Features and Application:

The Wieland Mini Milling Burs offer the following advantages:

Perfect compatibility with Wieland machines, ensuring optimal performance and precision.

Three different types of coatings provide versatility and adaptability for various dental applications.

Wide range of sizes and customizable lengths to meet specific milling requirements.

Capable of milling three types of dental prosthetic materials, allowing for diverse applications in dentistry.

These burs are suitable for dental laboratories, dental clinics, and prosthetic manufacturing facilities. They enable efficient and accurate milling of dental prosthetic materials, contributing to the production of high-quality dental restorations.

4.Production Details:

The production process of Wieland Mini Milling Burs involves advanced manufacturing techniques and strict quality control measures. Each bur is meticulously crafted to ensure durability, sharpness, and precision. The coatings are applied using state-of-the-art technology, guaranteeing optimal performance and longevity.

5.Product Qualification:

The Wieland Mini Milling Burs manufactured by Changsha Honchon Technology Co., Ltd. have obtained the necessary certifications and qualifications required for dental equipment and materials. They meet industry standards for quality, safety, and performance, ensuring reliable and consistent results.

6.Delivery, Shipping, and Serving:

We provide efficient delivery services to ensure prompt and reliable shipment of the Wieland Mini Milling Burs to our customers. Our dedicated customer service team is available to answer any inquiries and provide technical support. We are committed to delivering exceptional products and services to our valued customers.

7.FAQ:

Q1: Can the Wieland Mini Milling Burs be used with other milling machines?

A1: These burs are specifically designed to be compatible with Wieland machines for optimal performance. We recommend using them with Wieland machines for the best results.

Q2: Can the length and size of the burs be customized?

A2: Yes, we offer customizable lengths and sizes to meet specific milling requirements. Please contact our customer service team for further assistance.

Q3: What is the recommended maintenance for the burs?

A3: To ensure longevity and optimal performance, we recommend following the manufacturer's guidelines for cleaning, sterilization, and storage of the burs.

Choose the Wieland Mini Milling Burs by Changsha Honchon Technology Co., Ltd. for precise, efficient, and versatile milling of dental prosthetic materials. Experience the perfect compatibility and exceptional performance these burs offer for your dental milling needs.

.jpg)