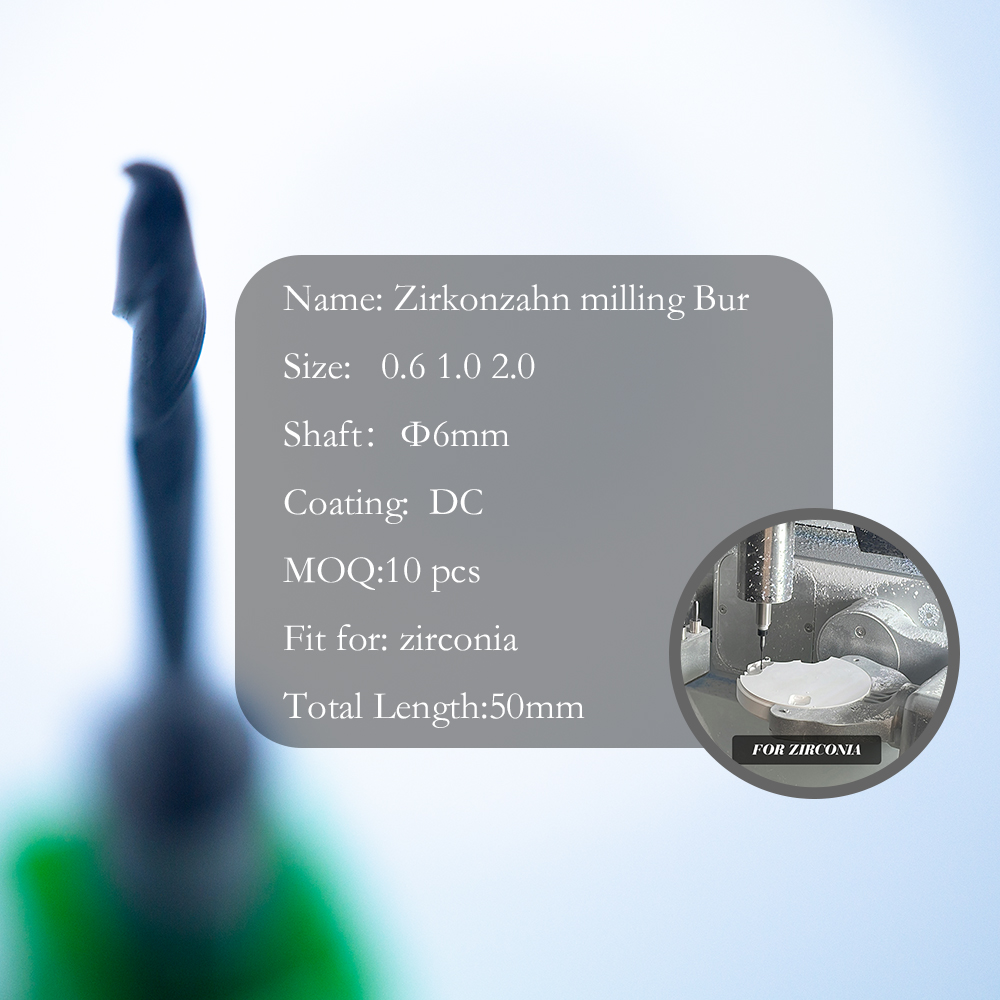

End mills dental tools used in various dental procedures, especially in milling machines and CAD/CAM systems. These tools are specifically designed to shape and cut different materials used in dental restorations, such as ceramics, zirconia, and titanium. Dental end mills come in different shapes and sizes, including cylindrical, ball-shaped, and tapered, to accommodate various dental milling applications.

End mills dental tools are crucial in creating precise and accurate dental restorations, as they enable dentists and dental technicians to carve out intricate details and achieve the desired shape and fit. The quality of the end mill plays a significant role in the final outcome of the dental restoration, ensuring smooth surfaces, clean margins, and accurate dimensions.

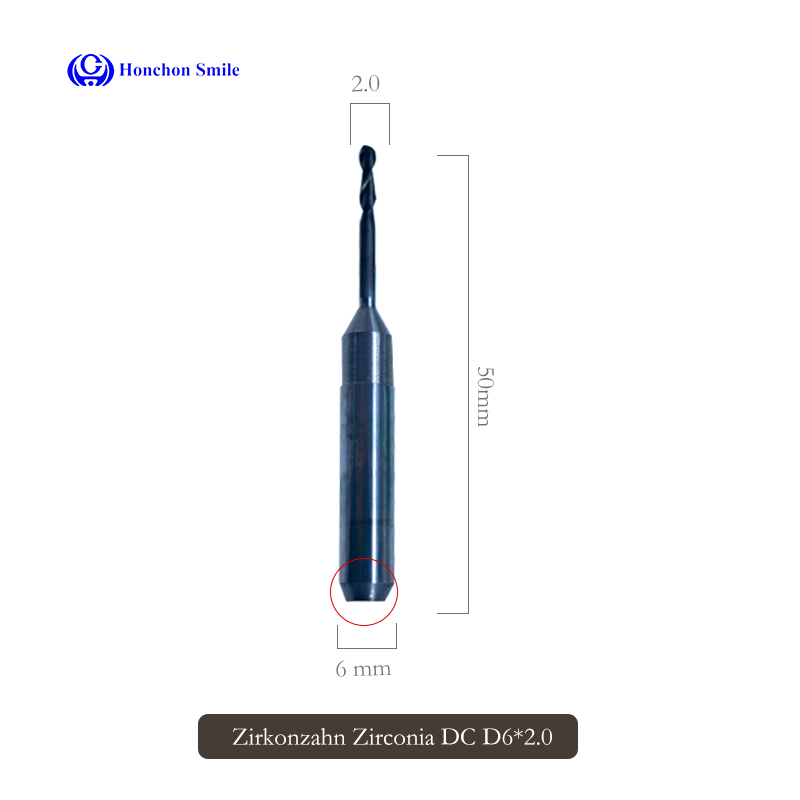

Additionally, some End mills dental tools feature special coatings, such as diamond-like carbon (DLC) or titanium nitride (TiN), to enhance their durability, reduce friction, and improve cutting performance. These coatings also help prolong the lifespan of the end mill, minimizing the need for frequent replacements.

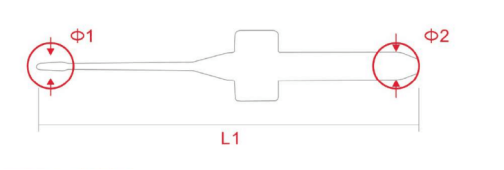

| CADCAM System | Function | Coating | Shaft Φ2/mm | Total Length L1/mm | headmeter Size/Φ1mm | ||

| Round | Flat | Toric | |||||

| Amann Girrbach | Milling Zirconia | DLC | Φ3mm | 47 | 2.5/1.0/0.6/0.3/ | 1.2/0.6 | / |

| RC | Φ3mm | 47 | 2.5/1.0/0.6/0.3/2.0 | / | / | ||

| DC | Φ3mm | 47 | 2.5/1.0/0.6/0.3/2.0 | / | / | ||

| Milling Emax | DC(Emery coating) | Φ3mm | 44 | 1.8/1.4/1.0/0.4 | 2.2 | / | |

| Miling Metal | / | / | / | 2.0/1.0 | / | / | |

| Miling PMMA | / | Φ3mm | 47 | 2.5/1.0/0.6/0.3/2.0 | 1.2/0.6 | / | |

.jpg)