Product Introduction:

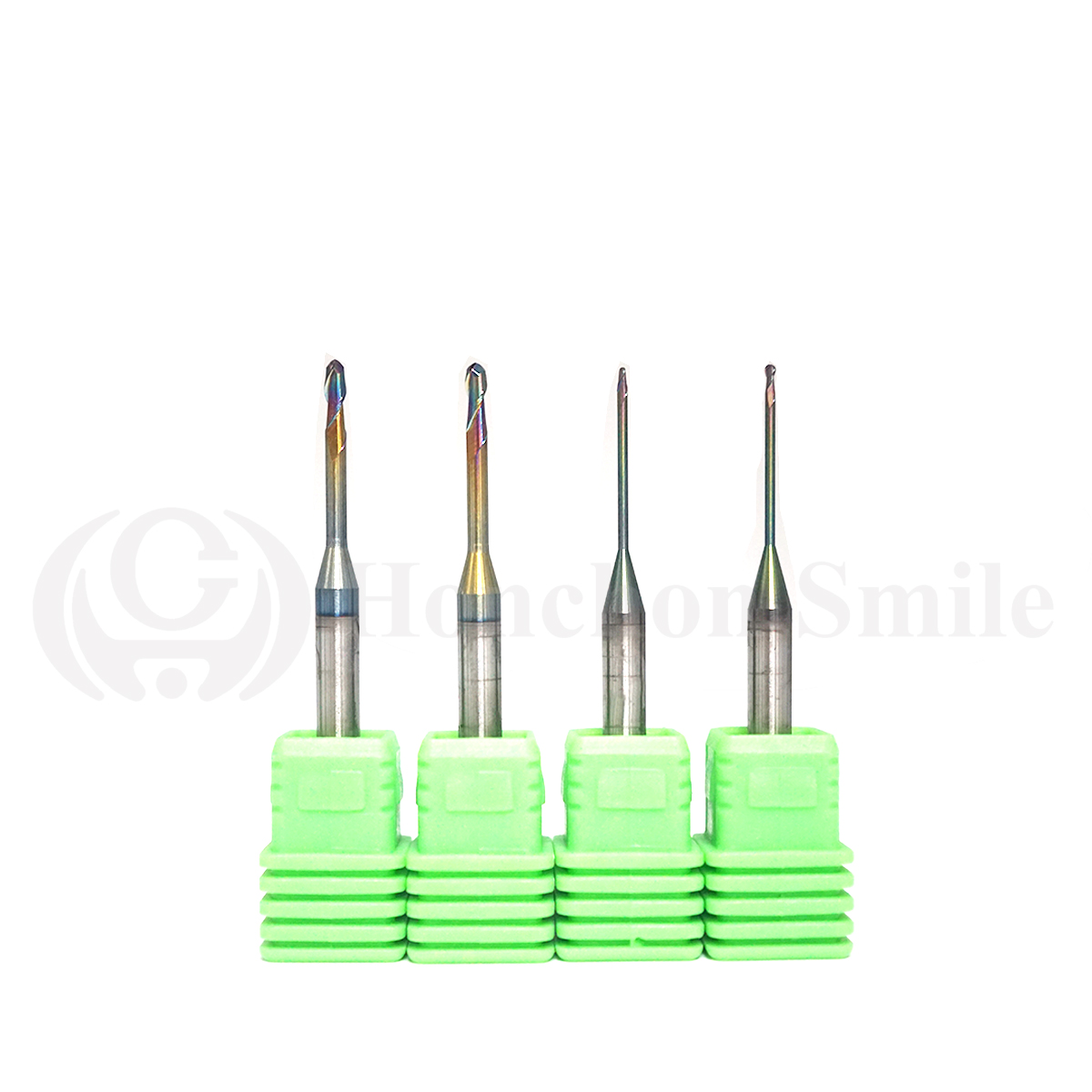

Introducing the premium range of Milling Burs from Changsha Honchon Technology Co., Ltd, meticulously engineered for seamless compatibility with Roland milling machines. Our Milling Burs are renowned for their long durability and exceptional performance, ensuring precision in dental restoration work. Enhanced with advanced DC, RC, and DLC coatings, these Milling Burs come in a comprehensive array of sizes and can be customized in length, diameter, and coating type. Ideal for milling a variety of dental prosthetic materials such as zirconia, PMMA, metals, and EMAX, the Honchon Milling Burs are the go-to solution for dental professionals seeking flawless results.

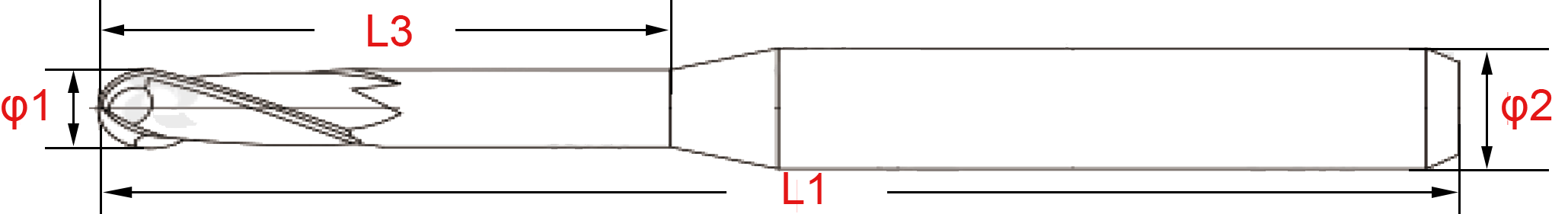

Product Parameters (Specification):

Coatings Available: Diamond Coated (DC), Resin Coated (RC), Diamond-like Carbon (DLC)

Compatibility: Specifically designed for Roland milling machines

Customization: Length, diameter, and coating can be tailored to requirements

Material Suitability: Zirconia, PMMA, metals, and EMAX

| Roland Milling Bur for Milling Zirconia | |||

| |||

| headmeter φ1 (mm) | Total Length L1 (mm) | Shaft φ2 (mm) | Type |

| 0.3 | 50 | 4 | DLC/RC/DC |

| 0.5 | 50 | 4 | DLC/RC/DC |

| 0.6 | 50 | 4 | DLC/RC/DC |

| 0.8 | 50 | 4 | DLC/RC/DC |

| 1.0 | 50 | 4 | DLC/RC/DC |

| 1.5 | 50 | 4 | DLC/RC/DC |

| 2.0 | 50 | 4 | DLC/RC/DC |

| 2.5 | 50 | 4 | DLC/RC/DC |

| 3.0 | 50 | 4 | DLC/RC/DC |

| Roland Milling Bur for Milling EMAX | |||

| |||

| headmeter φ1 (mm) | Total Length L1 (mm) | Shaftφ2 (mm) | Type |

| 0.5 | 40 | 3 | DC |

| 1.0 | 40 | 3 | DC |

| 1.5 | 40 | 3 | DC |

| 2.0 | 40 | 3 | DC |

| 3.0 | 40 | 3 | DC |

| Roland Milling Bur for Milling Metal | ||||

| ||||

| headmeter φ1 (mm) | L3 (mm) | L1 (mm) | Shaftφ2 (mm) | Type |

| 0.6 | 6 | 50 | 3 | / |

| 1.0 | 12 | 50 | 3 | / |

| 2.0 | 18 | 50 | 3 | / |

| 3.0 | 18 | 50 | 3 | / |

| Roland Milling Bur for Milling PMMA | |||

| |||

| headmeter φ1 (mm) | Total Length L1 (mm) | Shaftφ2 (mm) | Type |

| 0.3 | 50 | 4 | / |

| 0.5 | 50 | 4 | / |

| 0.6 | 50 | 4 | / |

| 0.8 | 50 | 4 | / |

| 1.0 | 50 | 4 | / |

| 1.5 | 50 | 4 | / |

| 2.0 | 50 | 4 | / |

| 2.5 | 50 | 4 | / |

| 3.0 | 50 | 4 | / |

Product Features and Application:

Our Milling Burs are crafted to offer unmatched durability and precision. The variety of coatings, such as DC, RC, and DLC, not only extend the life of the burs but also enhance their milling efficiency, allowing for smooth and precise cuts. These burs are perfect for dental practitioners who require versatility and reliability, as they are adept at milling diverse dental materials to create crowns, bridges, inlays, and veneers with impeccable accuracy. The customization option ensures that the Milling Burs can be adapted to any specific dental milling task.

Production Details:

At Changsha Honchon Technology Co., Ltd, we employ state-of-the-art manufacturing processes to produce Milling Burs that set the standard in the dental industry. Each bur is crafted with meticulous attention to detail to ensure it meets our stringent quality benchmarks. Our advanced production facility adheres to the highest standards, ensuring each Milling Bur upholds superior performance and reliability.

Product Qualification:

Every Milling Bur in our portfolio has undergone rigorous testing and quality assurance protocols to meet and exceed industry standards. The qualifications of our products are a testament to our commitment to providing dental milling solutions that practitioners can trust for their precision and longevity.

Deliver, Shipping, and Serving:

We ensure a streamlined delivery process, with carefully packaged Milling Burs shipped swiftly and securely to your doorstep. Our customer service team is dedicated to providing comprehensive support and is always ready to assist with any inquiries or after-sales service, guaranteeing a satisfactory customer experience from start to finish.

FAQ:

Can these Milling Burs be used on machines other than Roland?

While our burs are optimized for Roland machines, please consult with our customer service for compatibility with other systems.

How do I choose the right coating for my milling needs?

Our customer service team can assist you in selecting the appropriate coating based on the material you intend to mill and the desired outcome.

What is the lifespan of these Milling Burs?

The longevity of the burs depends on usage and material milled; however, our coatings are designed to maximize durability.

Can I order Milling Burs in sizes not listed in the standard offering?

Yes, we offer customization options to meet your specific milling requirements.

.jpg)