I. Introduction to Dental Milling Machines

a.definition

In the realm of dental technology, a dental milling machine stands as a highly specialized and advanced instrument that has revolutionized the way dental prosthetics are fabricated. At its core, this machine is a computer-aided manufacturing (CAM) device that allows dental professionals to transform a variety of solid materials into precise and tailored dental restorations. The materials it commonly works with range from the ever-popular zirconia to the malleable wax, the versatile polymethyl methacrylate (PMMA), composite resin, polyether ether ketone (PEEK), and an assortment of metals including titanium and cobalt-chrome.

The process begins with a digital design, often created through computer-aided design (CAD) software, which meticulously maps out the dental restoration with exact dimensions and aesthetics tailored to the individual patient. Once the digital design is finalized, it is sent to the dental milling machine, which uses an array of tools to carve out the restoration from a solid block of the chosen material. This process, known as subtractive manufacturing, involves the precise removal of material to achieve the desired shape and size of the dental prosthesis.

The ingenuity of these machines lies in their ability to perform complex cutting operations with high precision, ensuring that the final product not only fits perfectly but also perfectly replicates the appearance and feel of natural teeth. Compared to traditional manual denture fabrication methods, this level of precision is outstanding, and it is precisely this precision that makes dental milling machines an indispensable tool in modern dental laboratories.

B. Purpose

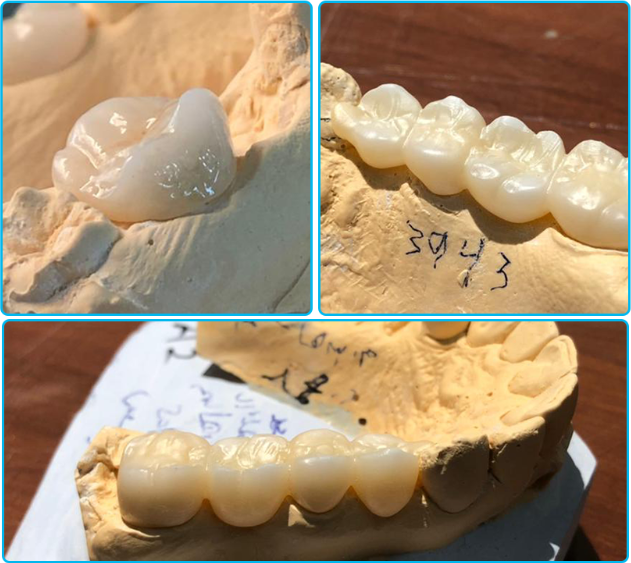

The primary objective of a dental milling machine is to create restorations that are of the highest quality in both structure and aesthetics. The range of restorations it can produce is extensive, including but not limited to crowns, which cap and protect damaged teeth; bridges, which fill the gaps left by missing teeth; inlays and onlays, which restore the biting surface of a tooth; and veneers, which improve the appearance of the front surfaces of the teeth. The machine can even produce full dental arches, providing solutions for patients who have experienced significant tooth loss.

The purpose of these machines extends beyond merely creating these restorations. They serve to provide dental professionals with the ability to offer customized, patient-specific solutions that are durable and fit with exacting precision. The use of dental milling machines in the production process means that restorations can be created much more quickly than traditional handcrafted methods, allowing for faster patient treatment and reducing the time a patient spends with temporary solutions.

Moreover, the purpose of these machines is to democratize quality dental care. By streamlining the production process and reducing labor costs, dental milling machines can help make high-quality dental prosthetics more accessible and affordable for a larger segment of the population. They facilitate a level of consistency and repeatability that is difficult to achieve with manual fabrication, ensuring that each restoration is as close to perfect as possible.

C. Importance

The importance of dental milling machines in contemporary dentistry cannot be overstated. They are the linchpin that connects the digital design phase to the tangible, physical restoration that is ultimately placed in the patient's mouth. The role they play in ensuring that patients receive restorations that are not only functional but also aesthetically pleasing is critical. In a field where the margin for error is incredibly slim, and the impact of a restoration on a patient's quality of life is significant, the precision and reliability offered by dental milling machines are invaluable.

These machines have fundamentally altered the landscape of dental restoration fabrication. Gone are the days of lengthy waits for handcrafted restorations, which could sometimes result in imperfections due to human error. Dental milling machines have introduced a new era of speed and precision, transforming the workflow within dental practices and labs. They have also played a significant role in the advent of same-day dentistry, where certain restorations can be designed, milled, and placed within a single patient visit—a feat that was unimaginable not long ago.

The aesthetic outcomes achieved with the help of these machines are remarkable. The ability to precisely mimic the translucency and color gradients of natural teeth means that restorations are virtually indistinguishable from natural dentition. This level of realism is not only important for the patient's self-esteem and comfort but also for the overall functionality of the teeth, as properly milled restorations can restore bite and chewing ability effectively.

In addition to the patient-centric benefits, the importance of dental milling machines extends to the operational efficiency of dental practices. They have become a cornerstone of modern digital workflows, integrating seamlessly with other digital dentistry tools such as intraoral scanners and CAD software. This integration streamlines the restoration process, from initial impression to final placement, reducing the potential for error and enhancing communication between the dentist, the laboratory, and the patient.

In conclusion, dental milling machines are more than just tools; they are a testament to the evolution and progress of dental technology. They stand as a beacon of innovation, pushing the boundaries of what is possible in dental restoration and ensuring that patients receive the highest standard of care with restorations that are precise, durable, and aesthetically pleasing. As technology continues to advance, the capabilities of these machines will only expand, further cementing their importance in the field of dentistry.

II. Features of Our Factory's Dental Milling Machine

A. High Precision

This device is a high-precision dental milling machine, our milling machine ensures that each dental restoration is crafted with the utmost precision. This high degree of accuracy is critical for the fit and finish of dental restorations, as even the slightest deviation can lead to discomfort or inadequate function for the patient.

The precision of our dental milling machines is not just a product of our advanced hardware but also a testament to the sophisticated software algorithms that drive the milling process. These algorithms are the result of extensive research and development, and they allow for the precise control of the milling tools as they navigate the complex geometries of dental restorations. The end result is a restoration that fits perfectly against the patient's existing dentition, maintaining the integrity of the bite and ensuring long-term comfort and durability.

B. Fast Production

Speed is of the essence in dental restoration, and the Changsha Honchon dental milling machine is engineered to deliver rapid production without sacrificing quality. Our high-speed spindle, capable of handling a wide range of materials, from soft waxes to tough metals, works in conjunction with advanced milling strategies to streamline the production process. These strategies are designed to optimize the milling paths, reducing the time it takes to produce a restoration while maintaining the precision and detail required for a high-quality prosthesis.

The combination of speed and efficiency in our dental milling machines enables dental clinics and laboratories to increase their throughput, ultimately allowing for faster patient treatment. The rapid turnaround time is particularly beneficial for practices offering same-day dentistry services, as it allows them to provide patients with permanent restorations in a single visit, greatly enhancing the patient experience.

C. Easy to Use

Ease of use is a core feature of the Changsha Honchon dental milling machine. We recognize that the operators of these machines come with varying levels of expertise, and our goal is to make the milling process as straightforward and user-friendly as possible. Our machines feature intuitive user interfaces that simplify the selection of materials, the loading of digital designs, and the monitoring of the milling process. This ease of use extends to maintenance as well, with automated calibration processes that ensure the machine remains in optimal condition for accurate milling.

The accessibility of our dental milling machine is not only beneficial for experienced technicians but also for those who are new to digital dentistry. We provide comprehensive training and support to ensure that all users can operate the machine with confidence, ultimately leading to better outcomes for patients and more efficient workflows for dental practices.

D. Cost-effective

Cost-effectiveness is a critical consideration for any dental practice or laboratory, and the Changsha Honchon dental milling machine is designed with this in mind. By minimizing material waste and optimizing the usage of consumables, our machine provides an economical solution for the production of dental restorations. The efficient use of materials not only reduces direct costs but also contributes to a more sustainable and environmentally friendly production process.

Furthermore, the reliability and speed of our milling machine reduce the need for remakes and adjustments, which can be costly and time-consuming. The initial investment in our dental milling machine is quickly offset by the savings in materials and labor, as well as the ability to take on a higher volume of cases, making it a wise financial decision for dental businesses looking to grow and thrive in a competitive market.

E. Durability

Durability is a hallmark of the Changsha Honchon dental milling machine. Constructed with top-quality components and engineered to withstand the demands of continuous operation, our machine is built for longevity. We understand that downtime can be disruptive to dental practices and laboratories, which is why we have gone to great lengths to ensure that our machines are reliable and require minimal maintenance.

The robust construction of our dental milling machines not only ensures consistent performance over time but also provides peace of mind for our clients. They can trust that their inves tment will continue to pay dividends for years to come, with a machine that maintains its precision and functionality even under the heavy workload of a busy dental lab.

In conclusion, the Changsha Honchon dental milling machine is a superior piece of technology that embodies precision, speed, user-friendliness, cost-effectiveness, and durability. These features come together to create a machine that is not just a tool but a cornerstone of modern dental practice. Our commitment to quality and innovation is evident in every aspect of our dental milling machines, and we stand behind our products with comprehensive training and support to ensure our clients achieve the best possible outcomes for their patients.

III. Technical Specifications

| Equipment size | 532*652*752mm | Processing methods | Five-axis linkage,dry milling |

| Weight | 103kg | Burs specilications | Special props for handle diameter 4mm |

| Rotating axis operating angle | A:360B:30-90° | Main axis speed | 0-60,000mp |

| Total power | 1.5KW | Working pressure | 4.7-7.5 bar (no water,no gasoline) |

| Toolmexne | 7 | stable air pressure | ≥6.0bar |

5 axis CADCAM milling machine Parts list

No. | Product name | Specification | Unit(/) | Quantity |

1 | HCE-M5X | 530-650-760( mm) | Set | 1 |

2 | Dust suction air pipe | 2m | Pc | 1 |

3 | 8mm air Pipe | 5m | pc | 1 |

4 | TY tee | 8 turn double 8 6 turn double 8 | Pc | 2 |

5 | Hoop | Vacuum pipe hoop | pc | 1 |

6 | Power cable | 3.5m | Pc | 1 |

7 | Screw driver | Phillips screwdriver and flat-blade screwdriver | Set | 1 |

8 | Allen wrench | 1-10 | Set | 1 |

9 | Tool Burs | ZIR bur size (2.0/1.0/0.6/1.5) PMMA bur size (2.0/1.0/0.6) | pc | 7 |

10 | pressure regulator filter | AFR2000 (installed on the machine) | pc | 1 |

11 | WAX | 98×14mm | pc | 1 |

12 | Lifting handle | 20-160mm | pc | 4 |

IV. Applications and Benefits

A. Dental Restoration

Changsha Honchon Technology Co., Ltd.'s dental milling machine is a virtuoso in the production of a wide array of dental restorations. Our cutting-edge machine is capable of crafting the most common forms of dental prosthetics, including crowns, bridges, veneers, inlays, onlays, and full dental arches, with a level of precision that is second to none. These restorations are essential for restoring function, improving aesthetics, and maintaining the structural integrity of patients' teeth, which is why precision is paramount.

The versatility of our dental milling machine allows dental professionals to expand their offerings, providing patients with a comprehensive range of treatment options. With the capability to work with a variety of materials, our machine can produce restorations that cater to the specific needs and preferences of each patient, whether they require the strength of zirconia, the flexibility of PEEK, or the aesthetic appeal of composite resin.

B. Enhance Quality and Accuracy

By integrating our dental milling machine into their workflow, dental labs can significantly enhance the quality and accuracy of their restorations. The precision engineering of our machine ensures that each prosthesis is milled to the exact specifications of the digital design, resulting in a superior fit and finish. This attention to detail leads to increased patient satisfaction, as the final restorations look and feel like natural teeth, and it also reduces the likelihood of remakes due to improper fit or aesthetic discrepancies.

The high-fidelity output of our dental milling machine also means that dental professionals can confidently present patients with restorations that are reliable and long-lasting. The accuracy of the milling process ensures that the restorations are designed to withstand the daily forces of chewing and biting, contributing to their longevity and reducing the need for future dental work.

C. Save Time and Cost

The efficiency of Changsha Honchon's dental milling machine translates directly into time and cost savings for dental labs. The rapid production capabilities of our machine allow labs to process a higher volume of restorations in a shorter amount of time, which is crucial for meeting tight deadlines and reducing the turnaround time for patients. This efficiency not only boosts the productivity of dental labs but also contributes to a more cost-effective operation by reducing labor costs and minimizing the time spent on each restoration.

Additionally, the cost savings extend to the patients, as the reduced production time and material waste translate into more affordable restorations without compromising on quality. Dental practices that utilize our milling machine can offer competitive pricing to their patients, making high-quality dental care more accessible to a broader population.

D. Increase Production Capacity

Our dental milling machine is designed to operate continuously, around the clock if necessary, which dramatically increases the production capacity of dental labs. This capability is particularly beneficial in today's fast-paced dental market, where the demand for dental prosthetics is growing. Labs equipped with our machine can keep up with this demand and even scale their operations to take on more work, leading to increased revenue and business growth.

The ability to run the machine for extended periods also means that labs can offer expedited services, such as same-day restorations, which are becoming increasingly popular among patients. This level of service can set a dental practice apart from its competitors and establish it as a leader in the field of digital dentistry.

V. How Our Dental Milling Machine Stands Out

A. Innovative Design

Changsha Honchon's dental milling machine features an innovative design that optimizes every aspect of the milling process. From the ergonomic arrangement of components to the streamlined user interface, every element of our machine is crafted to provide intuitive operation and easy maintenance. The design also facilitates quick material changes and tool adjustments, which further enhances the efficiency of the workflow.

Our machine's design is not only functional but also aesthetically pleasing, which means it can seamlessly integrate into the modern dental lab environment. The compact footprint of our machine allows for optimal use of space, making it suitable for labs of all sizes.

B. Advanced Technology

By incorporating the latest advancements in digital dentistry technology, our dental milling machine ensures that labs stay at the forefront of restoration fabrication. We leverage cutting-edge software and hardware innovations to provide a milling solution that is both powerful and precise. Our commitment to staying ahead of technological trends means that our clients benefit from continuous improvements and updates, keeping their operations current and competitive.

The advanced technology of our milling machine also includes features such as tool wear monitoring and automatic tool changing, which contribute to consistent milling results and reduce the need for operator intervention. These features not only streamline the milling process but also ensure that the quality of the restorations remains high over time.

C. Skilled Workforce

At Changsha Honchon Technology Co., Ltd., we understand that the quality of our machines is a direct reflection of the skill and dedication of our workforce. Our team comprises highly trained engineers, technicians, and support staff who are all committed to producing machines that meet the highest standards of quality and performance. We invest in the continuous training and development of our employees to ensure that they are equipped with the latest knowledge and skills to build and service our dental milling machines.

The expertise of our workforce is evident in every machine that leaves our factory, as each one is meticulously assembled, calibrated, and tested to ensure optimal performance. Our clients can rest assured that when they invest in a Changsha Honchon dental milling machine, they are receiving a product that has been crafted with care and precision by a team of professionals.

D. Exceptional Customer Service

Our commitment to our clients does not end with the sale of a dental milling machine; it is only the beginning. We pride ourselves on providing exceptional customer service, offering comprehensive training, support, and maintenance to ensure that our clients get the most out of their investment. Our customer service team is knowledgeable, responsive, and dedicated to resolving any issues that may arise quickly and efficiently.

We offer a range of services, from on-site installation and training to remote troubleshooting and software updates, all designed to keep our clients' operations running smoothly. Our goal is to build long-term partnerships with our clients, and we achieve this by being a reliable and supportive presence every step of the way.

VI. Conclusion

In conclusion, the dental milling machine from Changsha Honchon Technology Co., Ltd. is more than just a piece of equipment; it is a comprehensive solution that stands as a testament to precision, efficiency, and quality. With its array of features and benefits, our machine is an indispensable tool in the dental restoration process, enabling dental professionals to deliver exceptional care to their patients.

We invite dental professionals and lab technicians to experience the transformative impact of our dental milling machine on their workflow and output quality. Our machine is not just an investment in technology; it is an investment in the future of dental care.

For more information, demonstrations, or to place an order, please contact us at +8613055185196. lydia@honchon.comOur team is ready to assist you in integrating this cutting-edge technology into your practice, ensuring that you remain at the cutting edge of dental restoration excellence.

.jpg)