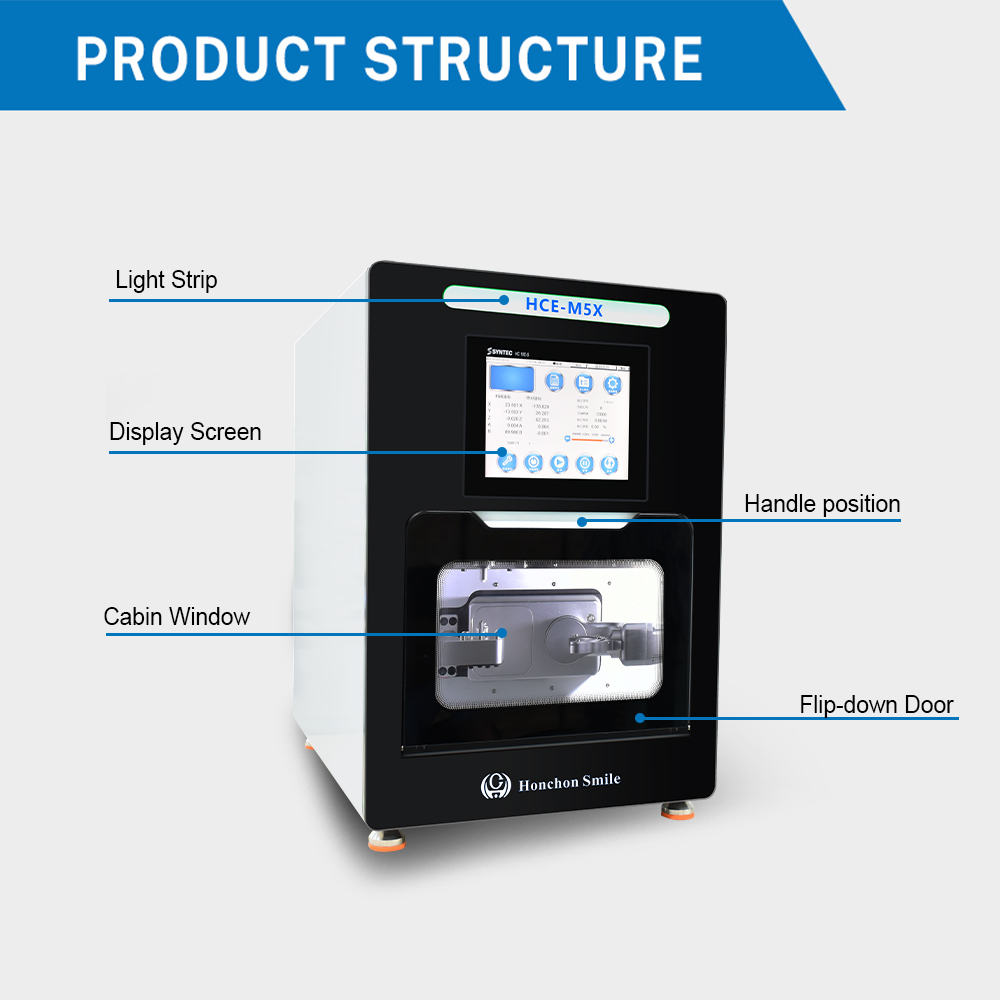

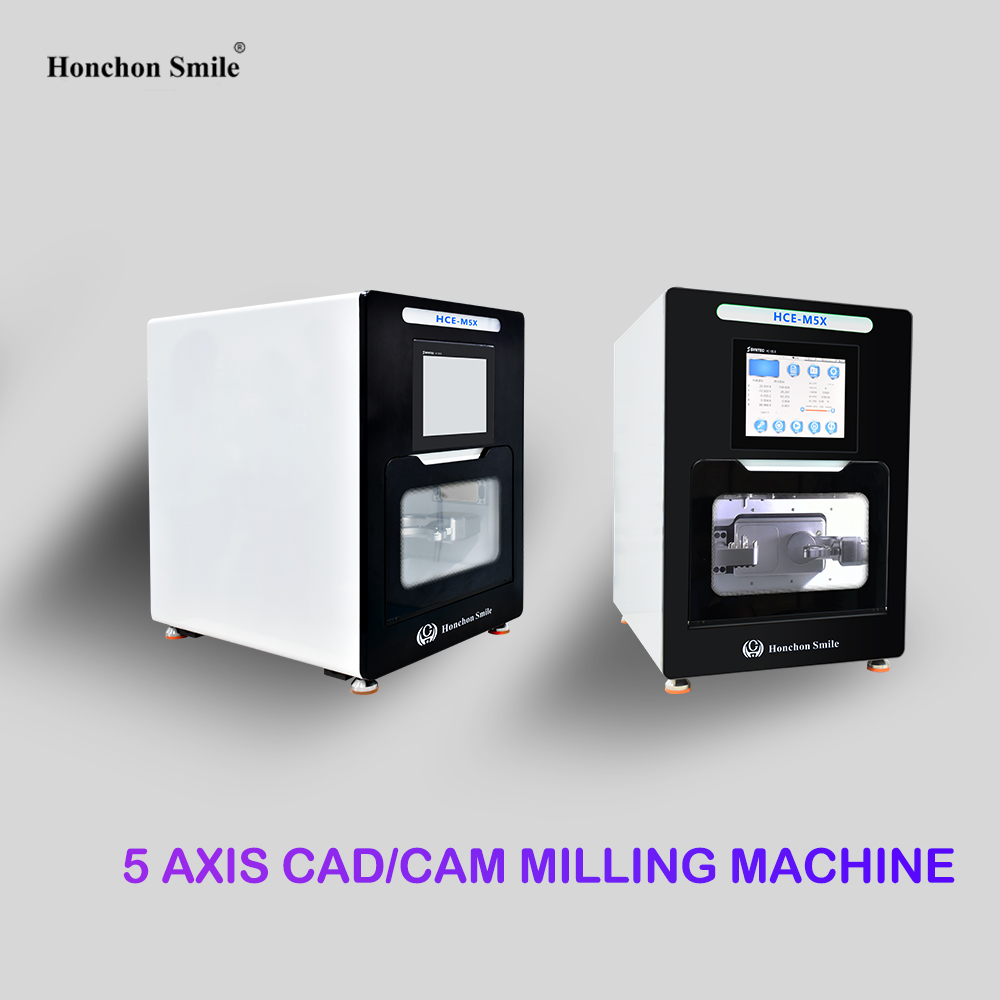

Product Name: High Performance 5-Axis Dental Milling Machine

Key Parameters:

- Dimensions: mm

- Weight: Net Weight: 162kg, Gross Weight: 186kg

- Rotational Axis Angles: A-axis: ±360°, B-axis: +35° to -91°

- Total Power: 1.5KW

- Spindle Speed: 0-60,000rpm

- Cutting Precision: 0.01mm

- Tool Capacity: 10 (2.0/1.0/0.6/1.5 for Zirconia, 2.0/1.0/0.6 for PMM & WAX)

- Tool Specifications: 4mm diameter tools, automatic tool changer, automatic tool detection

- Material Compatibility: 98mm discs of zirconia, wax, resin, composite materials

- Processing Time: Single crown: 15 minutes, three-unit bridge: 30 minutes

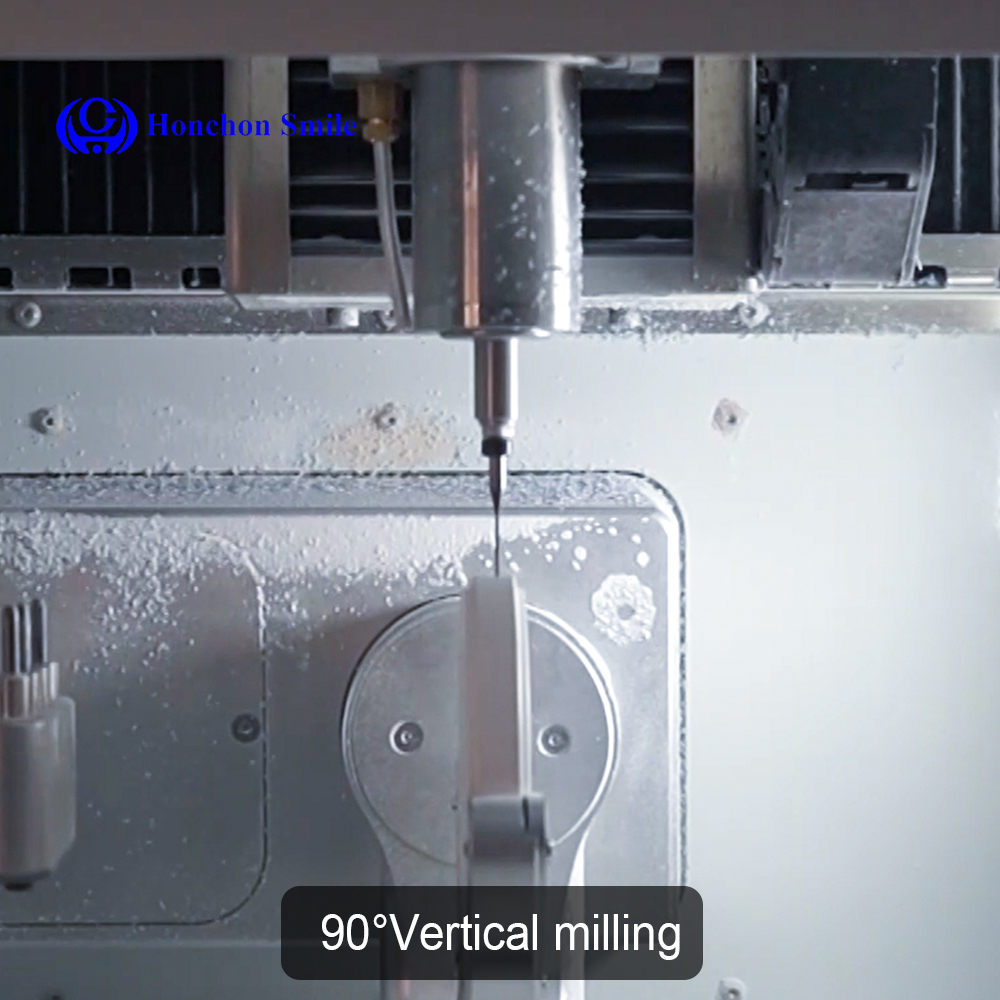

- Processing Method: Fully servo motor-driven, five-axis linkage, dry milling

Installation Requirements:

- Stable Voltage: 220-230V

- Stable Air Pressure: ≥6.0bar

- Temperature: 15-35°C

- Relative Humidity: <80%

Processing Capabilities:

- Can process inner crowns, full crowns, bridges, implant bridges, implant upper restorations, sleeve crowns, post and core crowns, inlays, onlays, etc.

Connectivity:

- USB/Ethernet (rear USB port, network cable interface)

Working Air Pressure:

- 4.5-7.5bar (oil-free)

CAM Software:

- Hyperdent / Millbox

Key Features

1. Upgraded B-Axis Swing:

- The B-axis swing range of +35° to -90° and the A-axis swing range of ±360° make it easy to mill large dental arches, undercuts, and large-angle zirconia abutments, expanding the processing range and addressing the challenges of complex dental restorations in the industry.

2. Three-Dimensional Processing:

- The intuitive 3D operation allows for precise engraving of individual tooth textures, perfectly adapting to complex implant bridges, and achieving high-end aesthetic restorations.

3. Innovative C-Type Fixture:

- The innovative C-type fixture design increases material utilization by 30% compared to traditional enclosed round metal fixtures, enhancing overall material efficiency.

4. High Speed and Intelligent Performance:

- Equipped with a powerful spindle capable of 60,000rpm, this dental milling machine offers exceptional cutting efficiency. The integrated intelligent memory system addresses issues related to sudden power outages or electrical anomalies, allowing for seamless continuation of interrupted tasks. This feature significantly enhances productivity and alleviates concerns for customers in markets like the Middle East, South Asia, and Africa.

5. Touchscreen Intelligence:

- The large touchscreen interface supports multiple languages and provides real-time processing status updates, alert notifications, and progress displays, ensuring an efficient and user-friendly experience.

6. User-Friendly Interface:

- The machine features a user-friendly interface with easy-to-navigate controls, reducing the learning curve and increasing productivity. This allows dental technicians to quickly adapt and operate the machine with minimal training.

7. High Reliability and Durability:

- Built with high-quality components, this dental milling machine ensures long-term reliability and durability, minimizing downtime and maintenance costs. The robust design can withstand continuous operation, making it ideal for busy dental labs.

8. Comprehensive Support and Training:

- We offer comprehensive support and training to ensure you get the most out of your investment. Our team of experts is available to provide technical assistance, maintenance tips, and operational training to maximize the machine's performance and longevity.

Installation Process

1. Unboxing and Inspection:

- Open the box and check if all accessories are complete.

2. Power Connection:

- Connect the machine to a 220V power source.

3. Air Connection:

- Connect to an air compressor.

4. Dust Extractor Connection:

- Connect the dust extractor.

5. Vacuum Hose and Linkage Line:

- Connect the vacuum hose and linkage line to the dust extractor.

6. Bur Installation:

- Install the milling burs.

7. Software Installation:

- Install the accompanying software.

This high-performance 5-axis dental milling machine is ideal for various complex dental restoration processes, particularly for high-precision, large-angle, and multi-material handling needs. Whether it's single crowns, bridges, or implant bridges, it can complete them efficiently and accurately.

By investing in our dental milling machine, you gain a competitive edge in the dental industry through enhanced productivity, superior quality, and exceptional reliability. Make the smart choice for your dental lab and elevate your restoration capabilities to the next level.

Contact information:

Tel +8613055185196,

WhatsApp +8613055185196

.jpg)