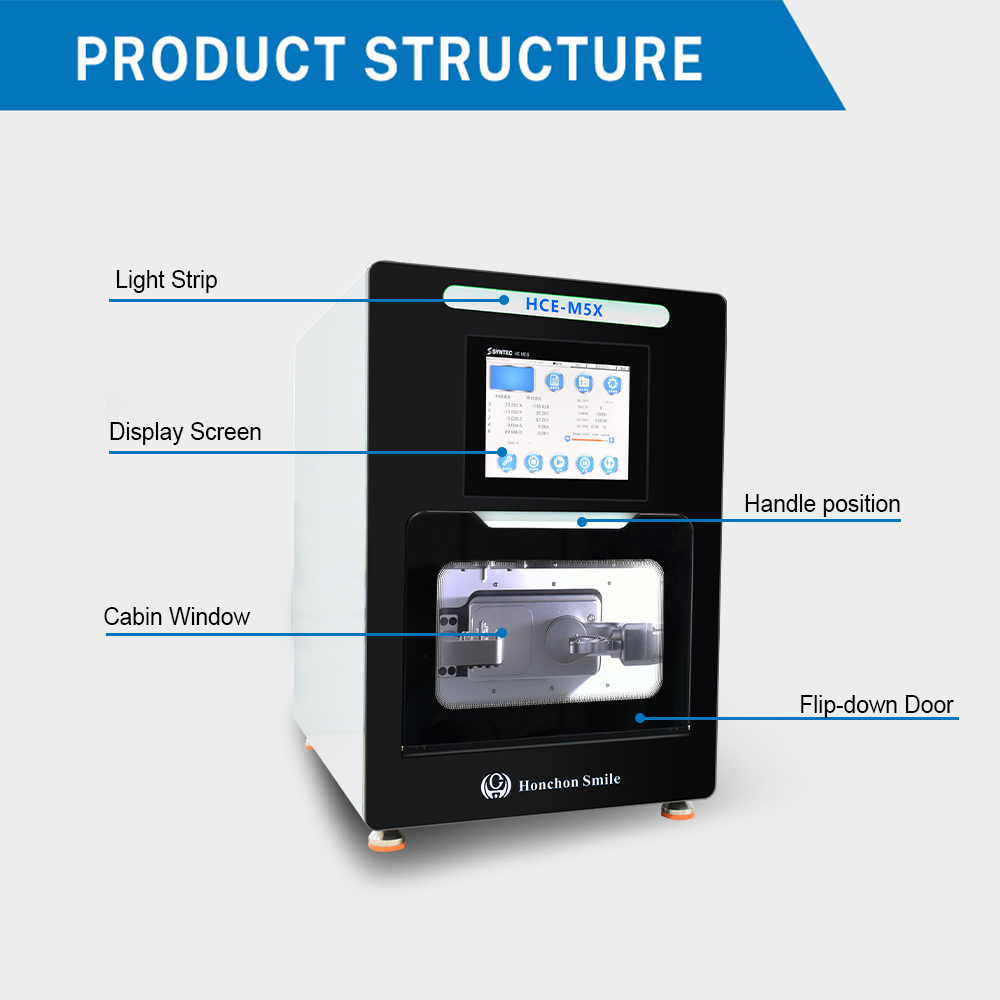

1.zirconia milling machine Description

Video introduction of zirconia milling machine

zirconia milling machine is a powerful choice for dry milling discs and blocks. Equipped with a high-speed spindle and an automatic changer for 7 tools, the powerful milling unit is designed for dental laboratories.

zirconia milling machine can be used for milling discs, blocks and wax blocks, PMMA blocks. The milling unit is capable of dry milling for various indications such as dental restorations, occlusal splints and dental models.

1 Safe use of precision tool settings and stroke protection design.

2. Quality assurance, the key components that affect the quality of the whole machine are high-quality accessories in China.

3. Stable performance The motor seat, bearing seat, and machine tool cast iron are integrally formed, with high rigidity, impact resistance, and no deformation, so that the tool seat maintains high rigidity and long life.

4 Environmental protection Fully enclosed design, double-layer dustproof system.

5 Long-lasting operation The excellent mechanical structure is the basis for ensuring mechanical precision and rigidity. It adopts international standard full Hana cast iron, integrally formed, no welding, and still maintains the original precision after many years of use.

2.Parameters of zirconia milling machine

| Equipment size | 532*652*752mm | Processing methods | Five-axis linkage,dry milling |

| Weight | 103kg | Burs specilications | Special props for handle diameter 4mm |

| Rotating axis operating angle | A:360B:30-90° | Main axis speed | 0-60,000mp |

| Total power | 1.5KW | Working pressure | 4.7-7.5 bar (no water,no gasoline) |

| Cutting precision | 0.2mm | Stable voltage | 220-230V |

| Toolmexne | 7 | stable air pressure | ≥6.0bar |

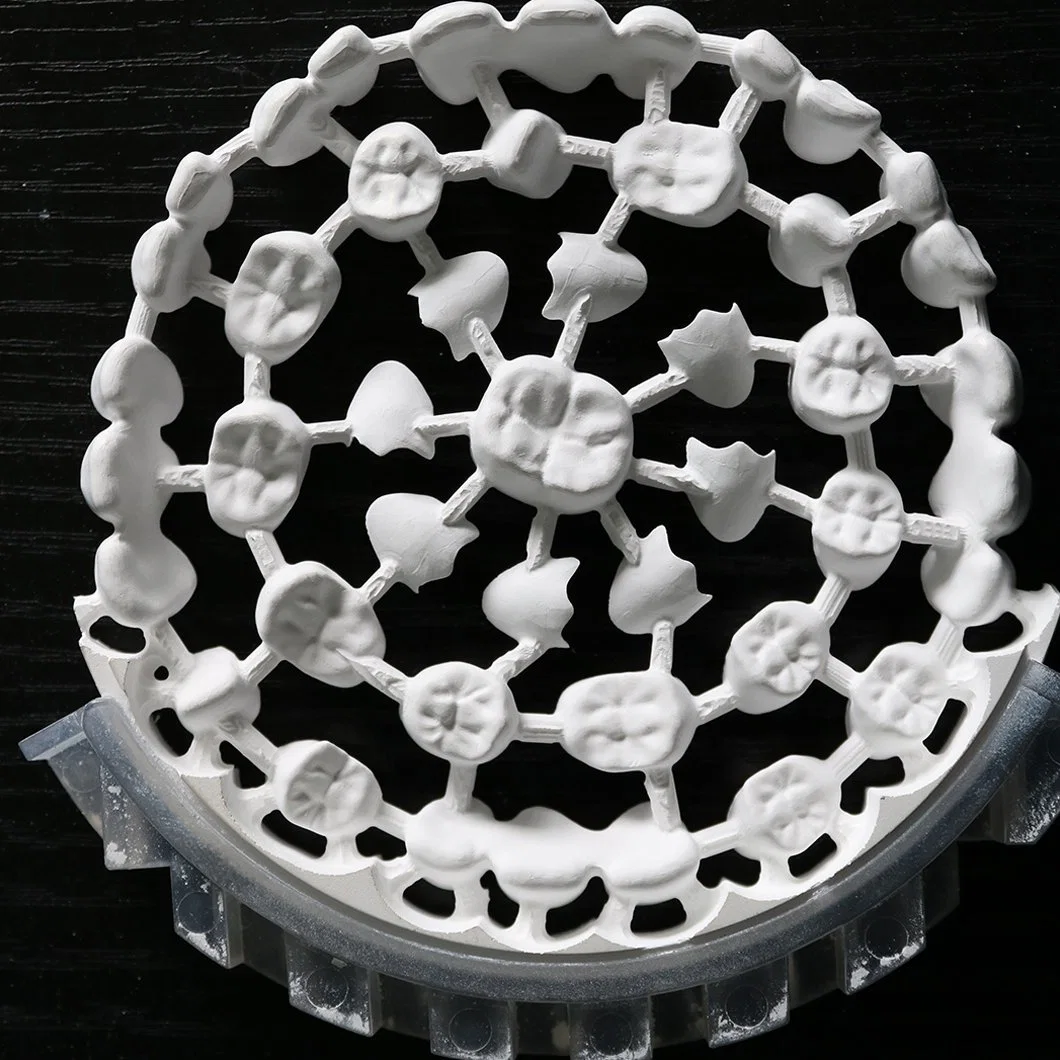

3.Zirconia milling machine can carve various denture shapes

.jpg)