1.product Introduction

Partial PEEK disc are a semicrystalline thermoplastic with mechanical and chemical resistance properties that are retained to high temperatures. It is more stable stronger and more adaptable than zirconia.Compared to the traditional metal and zirconium oxide,

Partial PEEK disc don’t need to be sintering and they are precision,low density,light weight and soft texture.Dental lab Peek blocks are used to fabricate items used in demanding applications, including bearings, piston parts, pumps, HPLC columns, compressor plate valves, and cable insulation. Partial PEEK disc is one of the few plastics compatible with high vacuum applications. Peek dental material don’t release any incompatibility with human beings. Patients can enjoy more comfortable and looked more beautiful.We are a proffessional dental lab materials supplier which supply quality PEEK blocks with affordable price and fast free shipping to worldwide. We purchase products with huge quantity to lower the cost as possible.

Whether a sample or batch quantity, our price is always competitive. if you have any problem in choosing or using the lab PEEK blocks, please feel free to contact us and we'll make every effort to solve the problem with you and make you 100% satisfied.

2.product Parameter (specification)

| PROPERTIES | PEEK | HUMAN SKELETON | ZIRCONIUMDIOXIDE(CERMAIC) | TETRIC CERAM |

| Density(g/cm³) | 1.32 | 1.8 | 6.0 | 1.2 |

| Bending strength (Mpa) | 160 | 1.49 | 1200 | 75 |

| Bending modulus(Gpa) | 4 | 17 | 210 | 2.8 |

3.Product application

Dental crown, bridge Gingival former

Provisional and perpetual abutment Attachment repair

Partial Denture Oral Splint

Inlay bridge Telescope crown

Denture Base Healing cap

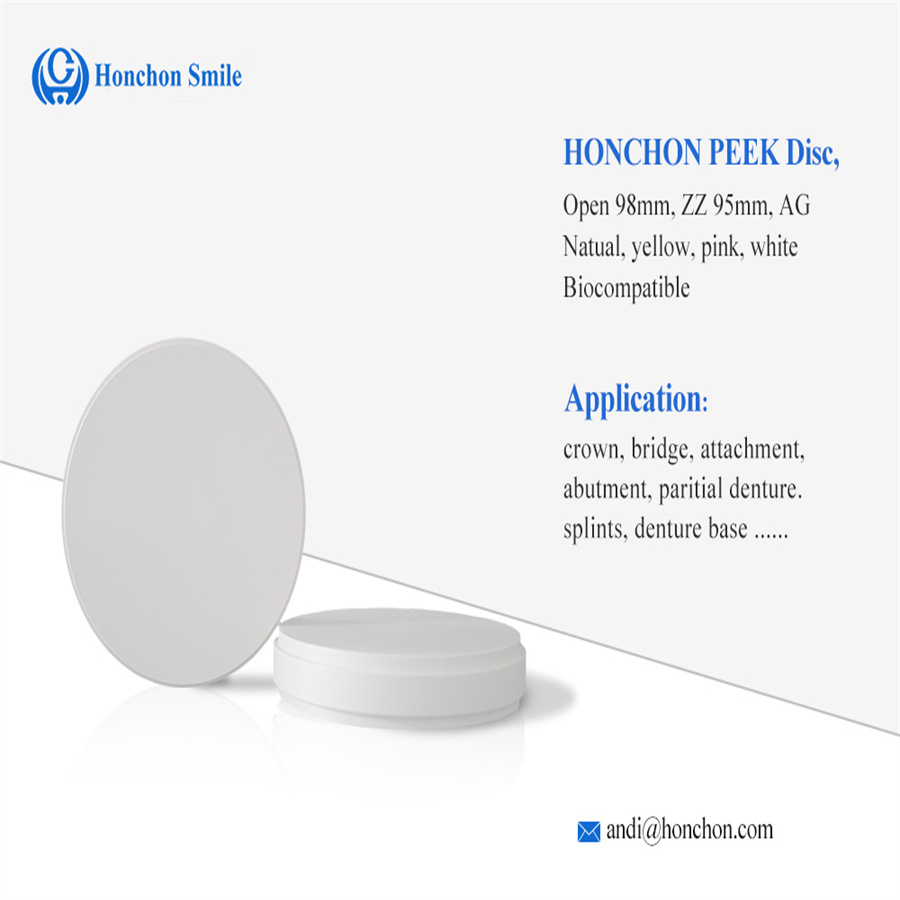

5.Available sizes and colors

| system | sizes | colors |

| Open CADCAM system | 98*14mm 98*16mm 98*18mm 98*20mm 98*22mm 98*25mm 98*30mm | white Nature yellow pink |

| Zirkonzahn system | 95*14mm 95*16mm 95*18mm 95*20mm 95*22mm 95*25mm 95*30mm | white Nature yellow pink |

| Amann girhach system | 92*75*14mm 92*75*16mm 92*75*18mm 92*75*20mm 92*75*22mm 92*75*25mm 92*75*30mm | Nature |

4.Issues to note during PEEK processing

CAD/CAM equipment must have air cooling or water cooling at the cutting point!

The processing strategy has PEEK material options in new equipment. For example, the equipment can choose PMMA material options. When reprocessing old equipment, it is recommended to reduce the speed (to 70% of the original speed) as appropriate to ensure cutting quality and protect the equipment.

It is best to use new needles when processing. Needles are not used for large losses. The processed products have burrs and require manual processing, which is troublesome.

.jpg)