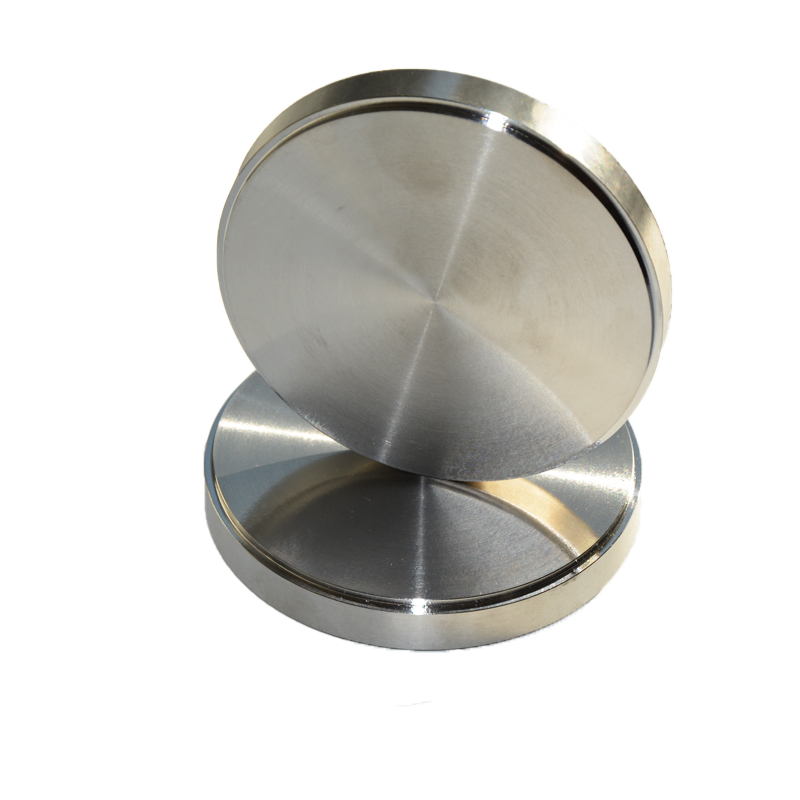

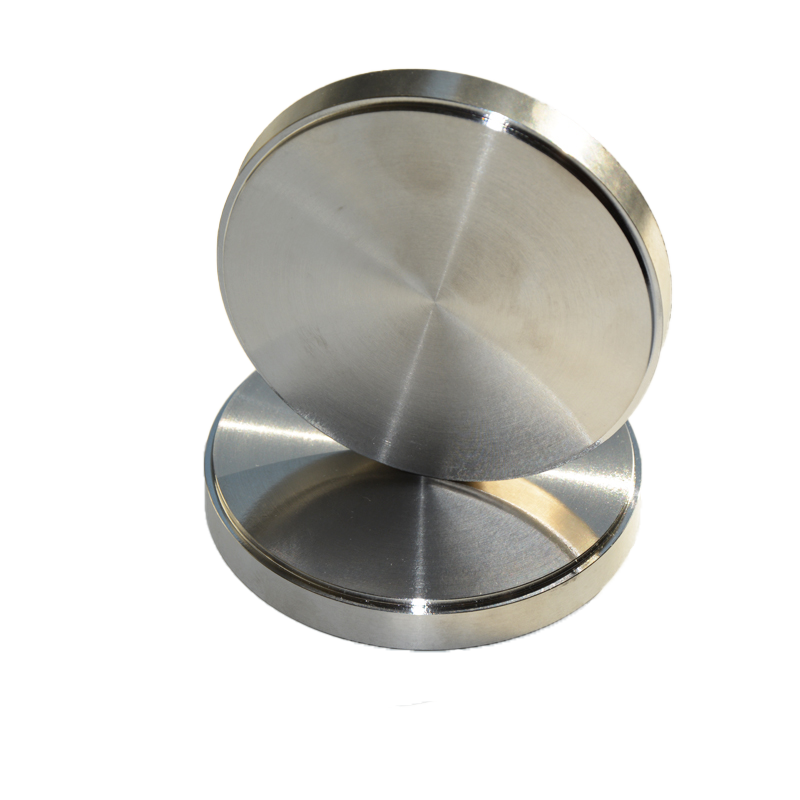

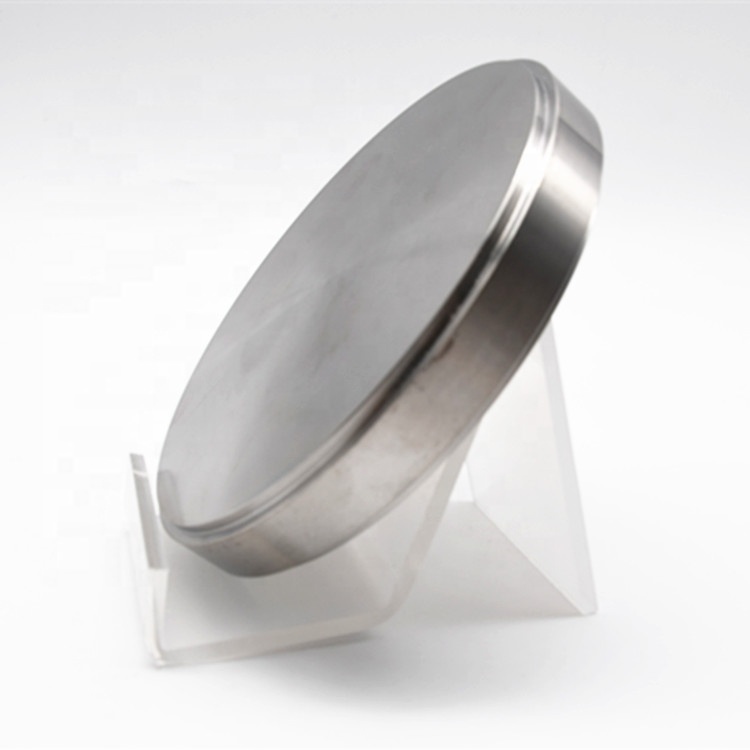

1.product Introduction

CADCAM dental titanium discs offer a range of advantages, including biocompatibility, corrosion resistance, high strength-to-weight ratio, precision milling, aesthetic results, longevity, and compatibility with digital workflows. CADCAM dental titanium discs find diverse applications in the fabrication of implant-supported restorations, removable partial dentures, screw-retained prosthetics, bar-supported overdentures, and custom abutments, contributing to the advancement of modern dental prosthetic solutions.

| Available sizes | 98*12 98*14 98*16 98*18 98*20 98*22 98*25 |

2.Product Advantages and application

Biocompatibility: Titanium is highly biocompatible and non-toxic, making it suitable for use in dental applications without causing adverse reactions in the oral cavity.

Corrosion resistance:Titanium exhibits excellent corrosion resistance, ensuring long-term stability and durability in the oral environment.

High strength-to-weight ratio: Titanium discs offer a superior strength-to-weight ratio, providing the necessary mechanical strength for dental restorations while remaining lightweight.

Precision milling:CADCAM technology allows for precise milling of titanium discs, enabling the fabrication of highly accurate and customized dental prosthetics.

Aesthetic results:Titanium can be used to create dental frameworks and substructures that provide strong support for aesthetic materials such as ceramics, resulting in natural-looking and durable restorations.

Longevity: Dental restorations made from titanium discs are known for their longevity and resistance to wear, making them suitable for long-term use in the oral cavity.

Compatibility with digital workflows: Titanium discs are compatible with digital design and manufacturing processes, facilitating the seamless integration of CADCAM technology in dental laboratories.

3.Product application

Implant-supported restorations: Titanium discs are used to fabricate frameworks for implant-supported crowns, bridges, and overdentures, providing stable and long-lasting solutions for missing teeth.

Removable partial dentures: Titanium discs can be utilized to create lightweight and durable frameworks for removable partial dentures, offering improved comfort and functionality for patients.

Screw-retained crowns and bridges: Titanium discs are employed in the production of screw-retained crowns and bridges, ensuring secure and stable attachments to dental implants.

Bar-supported overdentures: Titanium discs are used to manufacture bars that support overdentures, offering strength and stability for removable prosthetics in edentulous patients.

Custom abutments: Titanium discs can be milled to create custom abutments for dental implants, providing precise and customized solutions for implant restorations.

4.Prodection details

Raw Material Preparation:

High-quality titanium ingots or titanium sponge are the primary raw materials used in the production process. The raw material is selected based on its purity, mechanical properties, and chemical composition.

Melting and Casting:

The titanium ingots or sponge are melted in a vacuum or inert gas environment to prevent contamination. The molten titanium is then cast into molds to form titanium blocks of specific dimensions.

Hot and Cold Rolling:

The cast titanium blocks undergo hot and cold rolling processes to reduce their thickness and improve their mechanical properties. This step helps achieve the desired dimensions and mechanical integrity of the titanium blocks.

Annealing:

Annealing is performed to relieve internal stresses and improve the ductility and machinability of the titanium blocks. This process involves heating the titanium blocks to a specific temperature and then slowly cooling them to room temperature.

Surface Treatment:

The surface of the titanium blocks may undergo treatments such as chemical etching, polishing, or blasting to achieve the desired surface finish, cleanliness, and texture for further processing and dental applications.

Cutting and Machining:

The titanium blocks are cut into smaller sections or machined to the required shapes and dimensions using precision cutting tools, CNC machining, or other advanced manufacturing techniques.

Quality Control and Testing:

Quality control measures are implemented throughout the production process to ensure the dimensional accuracy, mechanical properties, and chemical purity of the titanium blocks. This may involve testing for properties such as tensile strength, hardness, chemical composition, and microstructure.

Sterilization and Packaging:

Once the dental titanium blocks have been manufactured and quality-checked, they are sterilized using appropriate methods to ensure cleanliness and biocompatibility. The sterilized blocks are then packaged in a manner that maintains their sterility and protects them from contamination until they are ready for use.

Overall, the production process of dental titanium blocks involves careful raw material selection, melting, casting, rolling, annealing, surface treatment, cutting, machining, quality control, sterilization, and packaging to ensure the production of high-quality and biocompatible titanium blocks for dental applications.

5.FAQ

What are CADCAM dental titanium discs used for?

CADCAM dental titanium discs are commonly used for milling and fabricating dental prosthetic frameworks, such as implant-supported restorations, screw-retained crowns and bridges, custom abutments, and bar-supported overdentures.

Are CADCAM dental titanium discs biocompatible?

Yes, titanium is highly biocompatible and non-toxic, making it suitable for use in dental applications without causing adverse reactions in the oral cavity.

What are the advantages of using CADCAM dental titanium discs over traditional methods?

CADCAM technology allows for precise milling of titanium discs, enabling the fabrication of highly accurate and customized dental prosthetics. Additionally, titanium offers excellent corrosion resistance, high strength-to-weight ratio, and compatibility with digital workflows.

Can CADCAM dental titanium discs be used for long-term restorations?

Yes, dental prosthetics fabricated from titanium discs are known for their longevity, wear resistance, and stability, making them suitable for long-term use in the oral cavity.

How are CADCAM dental titanium discs processed in dental laboratories?

CADCAM dental titanium discs are typically milled using computer-aided design and computer-aided manufacturing (CADCAM) systems, which allow for precise shaping and customization of dental prosthetic components.

Do CADCAM dental titanium discs require special handling or storage?

Dental titanium discs should be handled and stored according to the manufacturer's guidelines to maintain their cleanliness and integrity. Proper storage conditions, such as protection from contamination and controlled environmental factors, may be recommended.

What types of dental prosthetics can be fabricated using CADCAM dental titanium discs?

CADCAM dental titanium discs can be used to fabricate a wide range of dental prosthetics, including implant-supported crowns, bridges, custom abutments, screw-retained restorations, and bar-supported overdentures.

Are there specific milling machines or equipment required for processing CADCAM dental titanium discs?

Dental laboratories may use specialized milling machines or CNC equipment capable of handling titanium materials to ensure precise and efficient milling of CADCAM dental titanium discs.

.jpg)