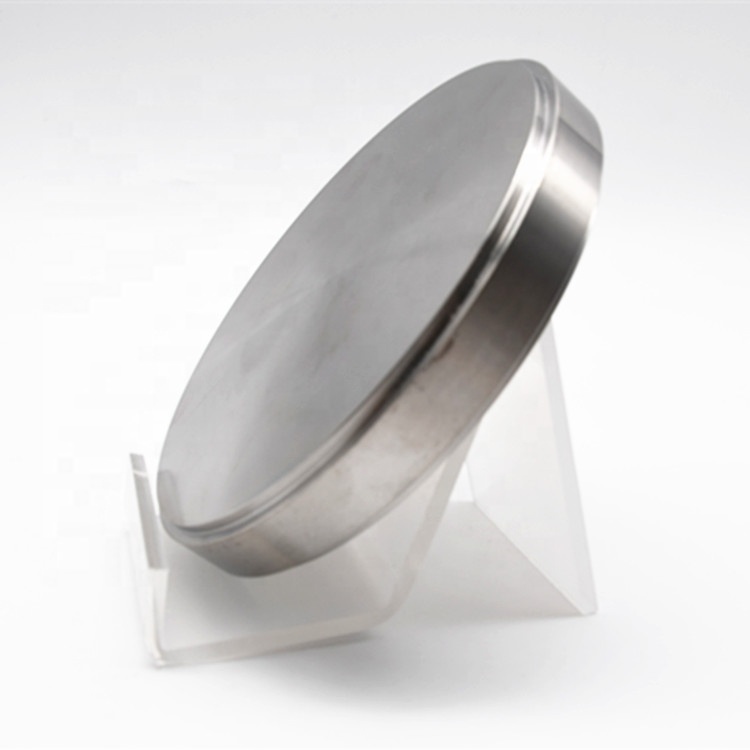

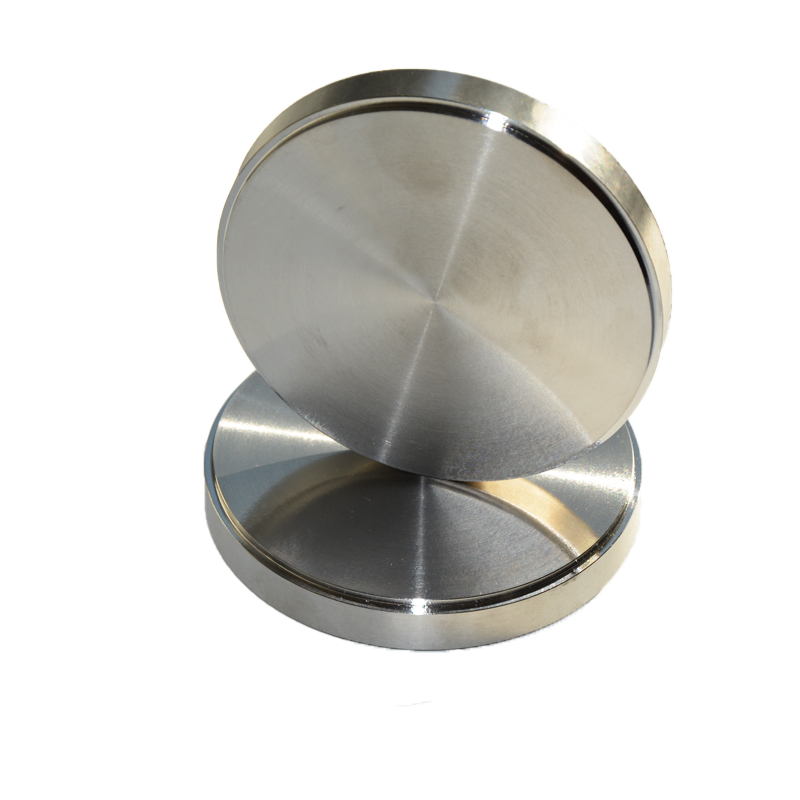

Honchon Dental Titanium Discs For crowns, bridges and implant restorations

We offer titanium discs in two models** Grade 2 titanium (Grade 2) and Grade 5 titanium (Grade 5)** with stable material and fine microstructure for various dental restoration solutions.

Grade 2 Titanium (Grade 2)

Suitable for general crown and bridge fabrication, characterized by good ductility, corrosion resistance, easier processing and suitable for daily clinical use.

Main components and properties:

Titanium content: pure titanium mainly

Tensile strength: ≥345 MPa

Yield strength: ≥275 MPa

Elongation: ≥20%

Sectional shrinkage: ≥30

Impurities control: C ≤ 0.08%, Fe ≤ 0.3%, N ≤ 0.03%

Grade 5 Titanium (Grade 5 / Ti-6Al-4V)

Ideal for restorative projects with higher strength requirements, such as crowns, bridges and implant restorations. This model strikes a good balance between strength and weight, being both strong and lightweight.

Main components and properties:

Aluminum (Al): 5.5-6.5%.

Vanadium (V): 3.5-4.5%

Tensile strength: ≥860 MPa

Yield strength: ≥795 MPa

Elongation: ≥10%

Sectional shrinkage: ≥25

Impurities control: C ≤ 0.08%, Fe ≤ 0.25%, N ≤ 0.05%, H ≤ 0.012%

Product Advantages

Fine microstructure, easy for precision processing

Good material stability, small dimensional changes after processing

Support high strength load, not easy to break after long-term use.

Applicable to various CAD/CAM systems

Cases & Feedback

.jpg)