What do CNC machine tools have two axes, three axes, and five axes?

2024-05-07

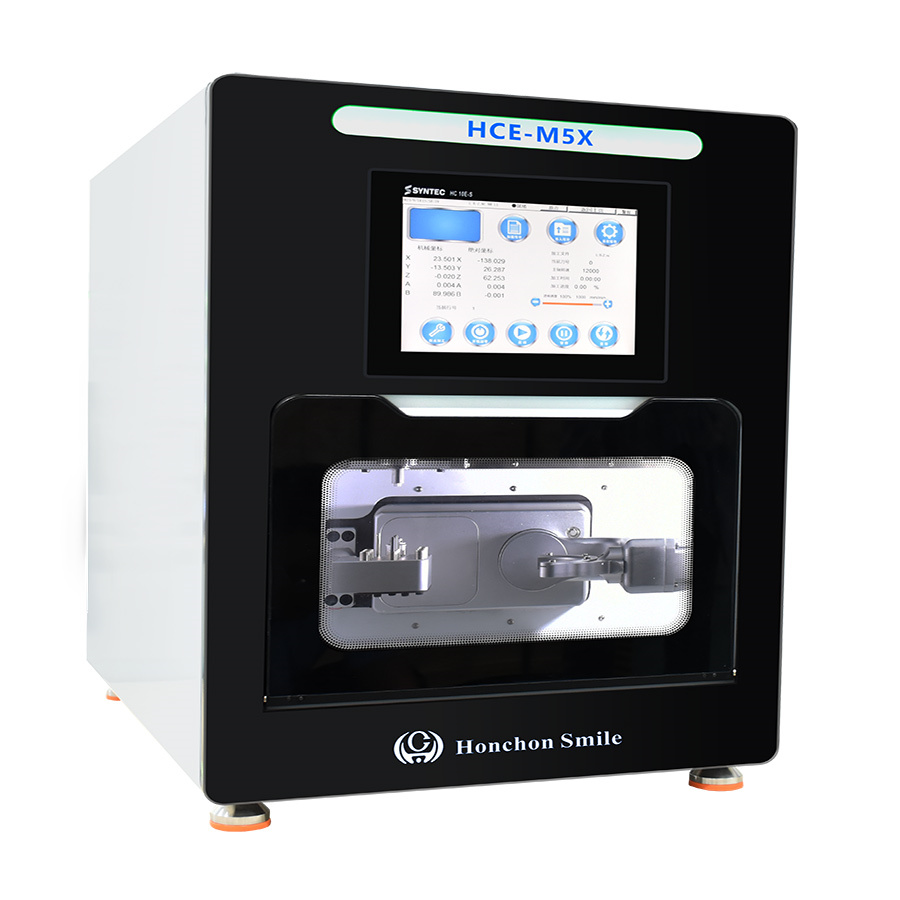

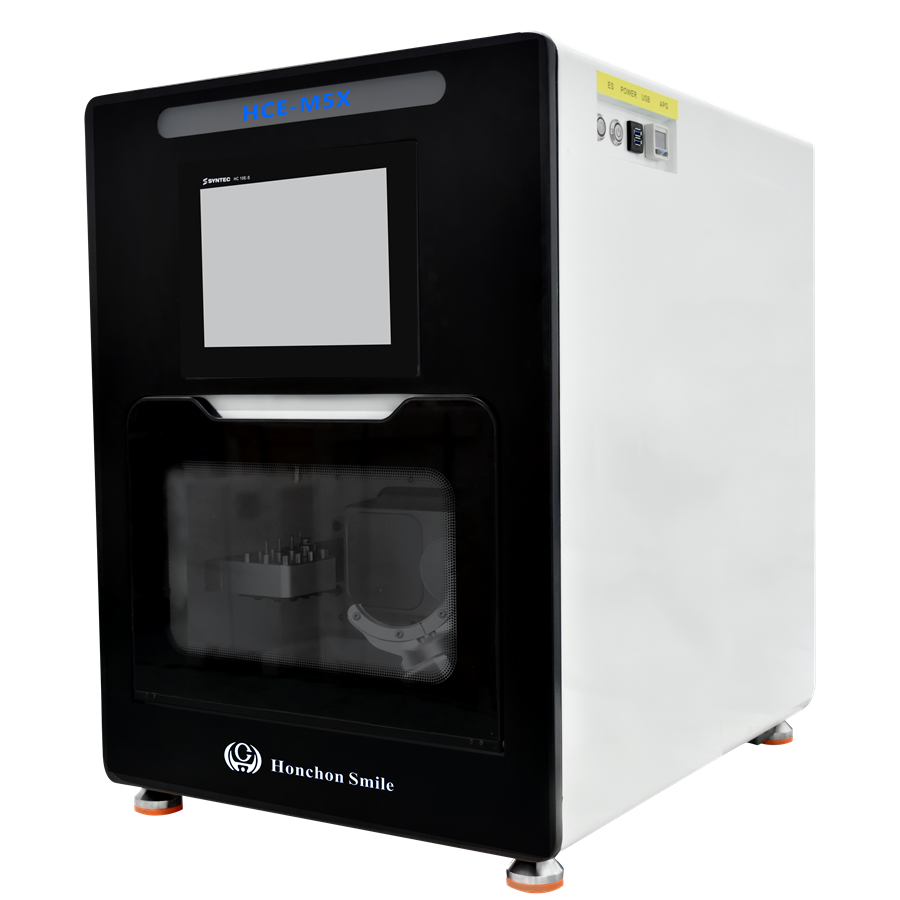

Five-axis is a high-end CNC machine tool and is also the development trend of CNC, such as five-axis teaching machine tools, five-axis milling machines, five-axis engraving machines, etc. Two and a half axes refers to three axes and two linkages. The current CNC equipment such as vertical machining should have three axes as standard (the standard configuration of horizontal machining is usually three and a half axes), but there will be three and a half axes of vertical or horizontal machining. Plus, the half-axis of three-and-a-half-axis vertical adding or horizontal adding generally refers to the indexer. Since the indexer cannot be linked with other axes during processing operations and can only rotate or move independently, it becomes a three-and-a-half-axis. If the indexer is replaced with a turntable , that is, four-axis equipment is realized. The two-and-a-half-axis you mentioned are currently more commonly used in drilling machines. Since the drilling machine only needs to move vertically when drilling, in the case of XY linkage positioning, the Z-axis moves, so for Two and a half shafts.

Multi-axis has a wide range of uses and can process complex curved surfaces. It can process multiple curved surfaces with one clamping and positioning, ensuring accuracy, saving processing time and releasing manual labor.