1.Introduction of lithium disilicate blanks

HONCHON's lithium disilicate blanks are of very good quality, comparable to the highest-end brands in the industry, but at a much better price, which is very

cost-effective. Our lithium disilicate blanks are available in a wide range of colors to meet different restorative needs. Lithium disilicate blanks are suitable for

all types of dental restorations, especially veneers, crowns and inlays on anterior and some posterior teeth.

2.Core advantages of lithium disilicate blanks:

One-shot molding process with water ripple appearance:

Our lithium disilicate blanks utilize a one-shot molding process similar to that used in Europe and the United States, which results in a fine water ripple effect

on the surface of the blocks. This process is accomplished by direct extrusion and condensation at high temperatures, allowing the blocks to be formed without

additional grinding or cutting. This reduces the risk of internal defects in the blocks.

Compared to other brands in China, lithium disilicate blanks using the traditional casting or flat cutting process often suffer from the following problems:

The flat cutting process used by aidite gives the blocks an angular, square shape, and the holes are easy to see when magnified and are prone to breakage

during transportation;

Upcere and some other companies use a traditional casting process where the surface of the blanks is not flat enough and can be uneven and not

homogeneous internally.

HONCHON SMILE's high-temperature condensation process ensures that lithium disilicate blanks have a more homogeneous surface and structure, reducing

the defects that can occur with conventional processes.

High temperature melting system:

A 99.9% pure platinum high temperature melting system is used, which makes lithium disilicate blanks flatter and stronger at high temperatures. Compared

with other brands of lithium disilicate blanks, HONCHON's lithium disilicate blanks have a flatter surface, no impurities can be seen when magnified, and the

quality is more stable.

Complete range of color numbers and translucency:

Our Lithium Disilicate blanks are available in a full range of colors, especially in MT Medium Translucency, which exceeds the industry standard. The medium

translucency shades are especially suited for those anterior restorations that require a natural transitional shade that better mimics the clarity and shade

difference of natural teeth.

Advantageous comparison:

Fewer internal defects: through the one-shot molding process and the platinum melting system, the internal and surface quality of the porcelain blocks

is guaranteed to have fewer internal defects and cosmetic problems than other products that use cutting or traditional casting processes.

Excellent surface quality: The water ripple surface treatment improves the aesthetics of the porcelain blocks and also reduces the risk of breakage

during processing and transportation, avoiding common problems such as cracks and breakage caused by processing or transportation.

Stable high-temperature treatment: The use of platinum high-temperature melting systems ensures the stability and uniformity of the porcelain blocks,

reducing common thermal stress cracks and uneven internal and external structures.

3.Field of application of lithium disilicate blanks:

Suitable for all types of dental restorations, especially veneers, crowns and inlays on anterior and some posterior teeth.

4.Parameters of lithium disilicate blanks:

Three-point flexural strength after crystallization: 420±60Mpa

Density after crystallization: 2.46~2.52g/cm3

Thermal expansion coefficient after crystallization: (CTE50-500℃)10.5*10-6K-1

Linear shrinkage: 0.0010-0.0026 (≈0.2%)

Vickers hardness HV1: 6500Mpa±200Mpa

5.Available colors of lithium disilicate blanks:

| Shade Transparency | A1 | A2 | A3 | A3.5 | A4 | B1 | B2 | B3 | B4 | C1 | C2 | C3 | C4 | D2 | D3 | D4 | BL1 | BL2 | BL3 | BL4 |

| HT | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | ||

| MT | √ | √ | √ | √ | √ | |||||||||||||||

| LT | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ |

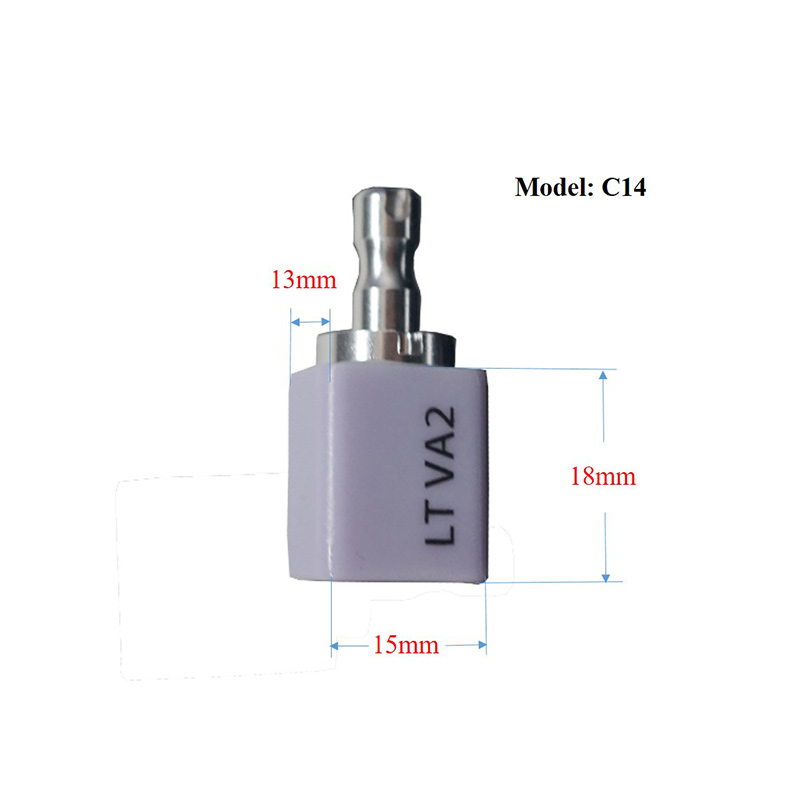

6.Optional handle for lithium disilicate blanks

.jpg)