1. Lithium Disilicate Introduction

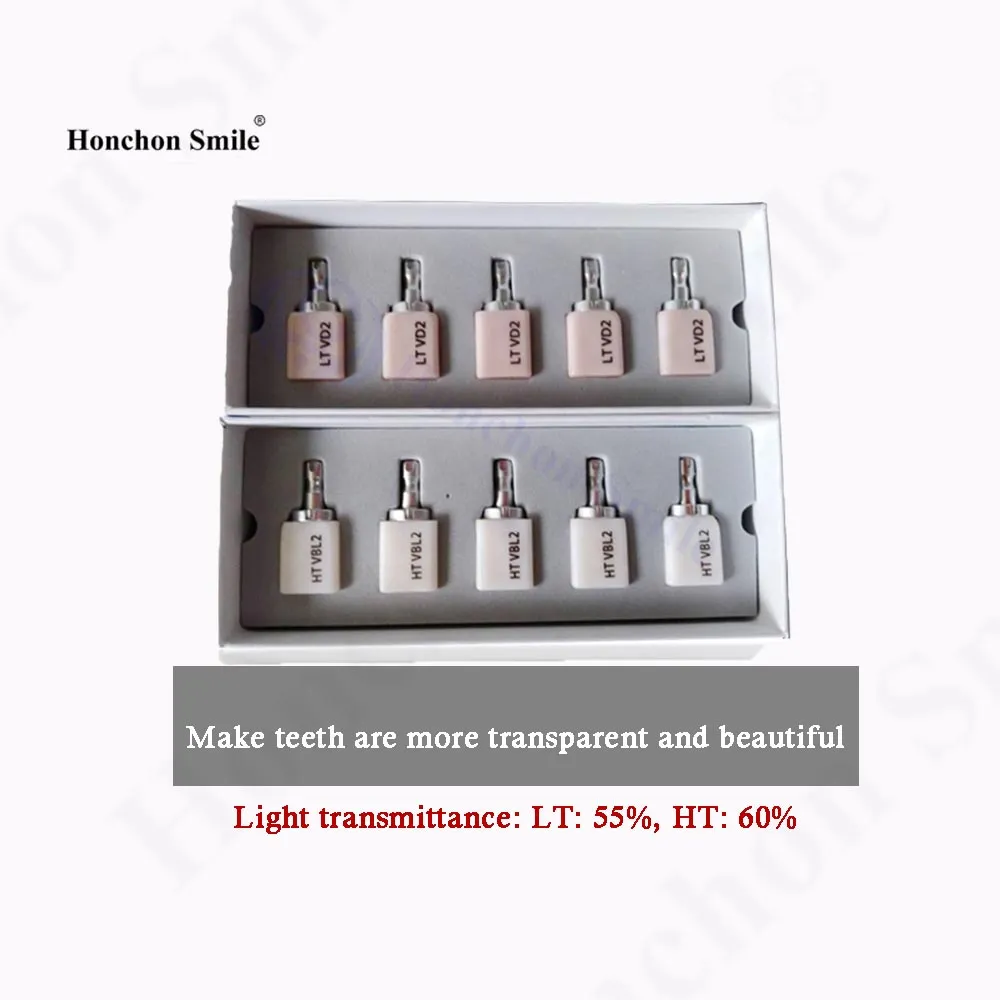

Lithium Disilicate Blocks are a premium dental restoration material, known for their superior mechanical strength and exceptional translucency. These blocks are designed for easy cutting, which prolongs the life of milling burs, and they deliver brilliant aesthetics that make them ideal for chairside instant restorations.

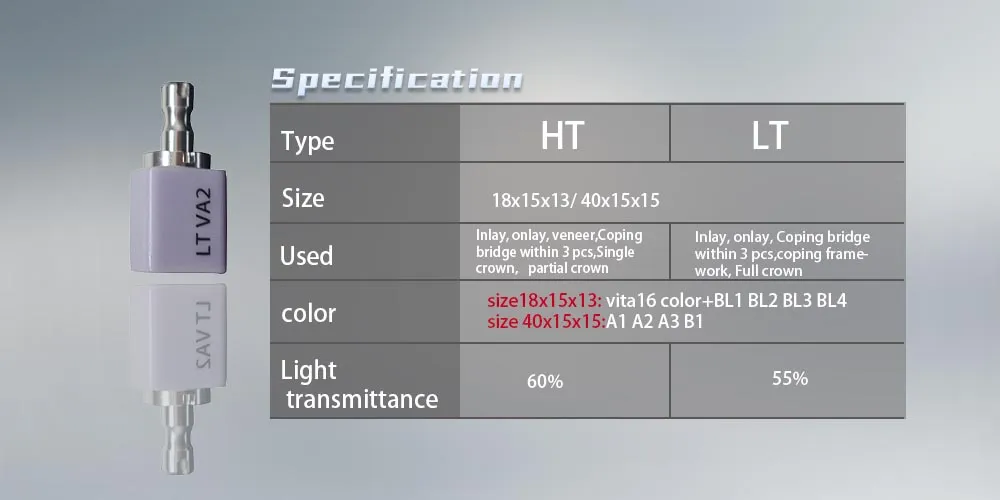

2. Lithium Disilicate Parameter (Specification)

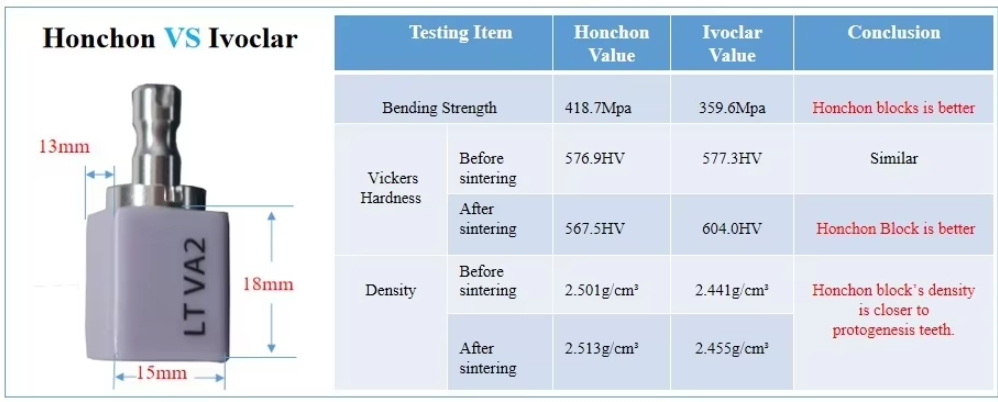

- Density: 2.4-2.7 g/cm³

- CTE (25-500°C): (8.5-11) x 10⁻⁶K⁻¹

- Vickers Hardness: 5400 ± 400 MPa

- Chemical Solubility After Sintering: <100 μg/cm²

- Crystallization Temperature: 840-850°C

- Composition:

- SiO₂: 58.5%-72.5%

- Li₂O: 13%-15%

- K₂O: 3%-5%

Other Oxides: 7.5%-25%

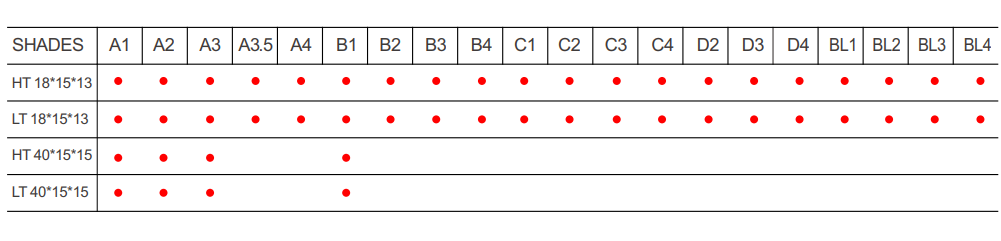

Available sizes and colors

3. Characteristics and application of lithium disilicate blocks

Key Features:

- Easy to Cut: Prolongs the life of the burs, making the milling process more efficient.

- Excellent Mechanical Strength: Provides durability and reliability for long-lasting restorations.

- High Translucency: Ensures brilliant aesthetics, closely resembling natural teeth.

- Chairside Instant Restoration: Ideal for quick and effective restorations, reducing patient wait time.

Applications:

- Crowns

- Bridges

- Veneers

Inlays and Onlays

4. Details of lithium disilicate block

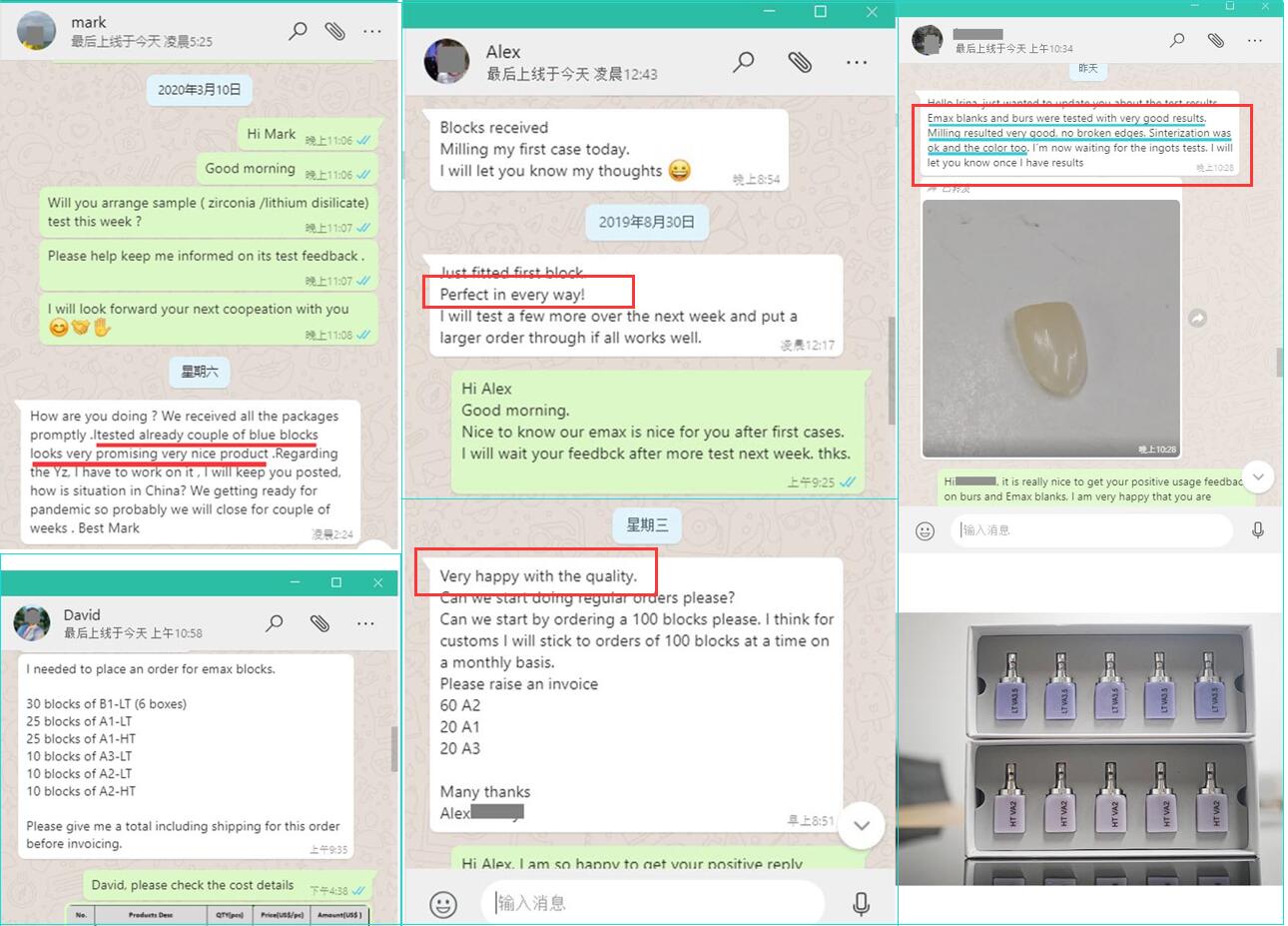

Our Lithium Disilicate Blocks are meticulously engineered to meet the highest industry standards. The production process includes strict quality control measures to ensure consistency in strength, translucency, and color. Each block is designed for precision milling and is easy to handle, providing excellent results with minimal adjustment.

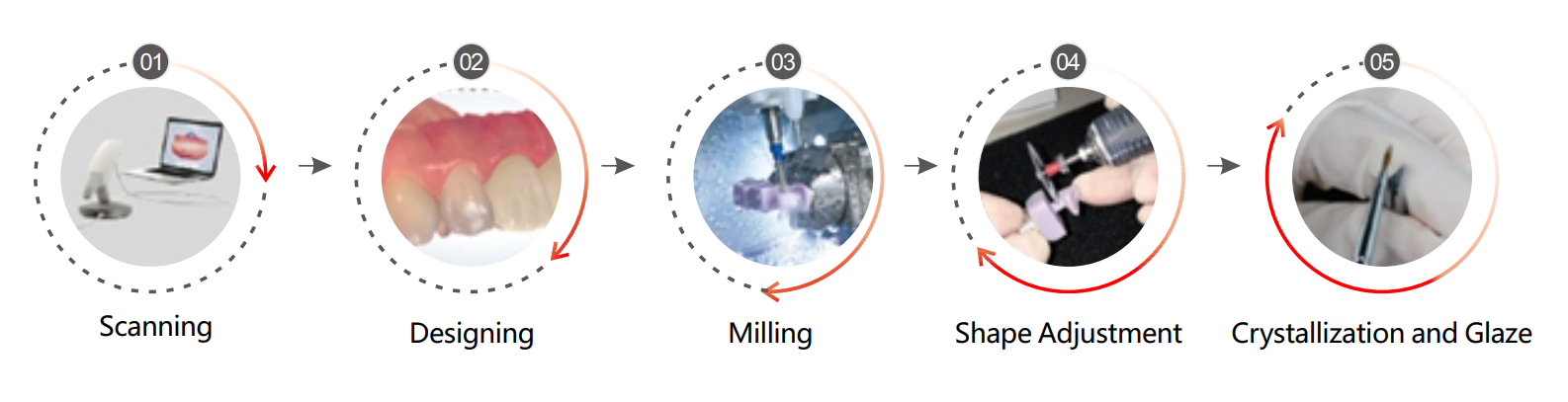

5. The process of making dentures using lithium disilicate blocks

- Processing process: Adheres to the calcining curve for optimal results:

- Initial Temperature: 450°C

- Drying Time: 4 minutes

- Heating Rate: 40°C/min

- Highest Temperature: 840°C

- Hold Time: 6 minutes or 2 minutes

Final Temperature: 300°C

- Certification and qualification of lithium disilicate blocks:

- ISO 13485 certified

- FDA and CE certified

- Each batch is rigorously tested for compliance with international standards.

6. Deliver, Shipping, and Serving

- Delivery & Shipping:

- Lead time: 2-3 working days, delivery time for large quantity orders can be negotiated.

- Secure worldwide delivery with careful packaging to ensure the product’s integrity.

- After-Sales Service:

- 2-year warranty on manufacturing defects.

Comprehensive technical support and customer service available 24/7.

7. FAQ

Q: What are the advantages of Lithium Disilicate Blocks?

A: They offer easy cutting, superior mechanical strength, and high translucency, making them ideal for aesthetic restorations.

Q: What is the recommended sintering process?

A: Follow the specified calcining curve for optimal results, with an initial temperature of 450°C and a maximum of 840°C.

.jpg)