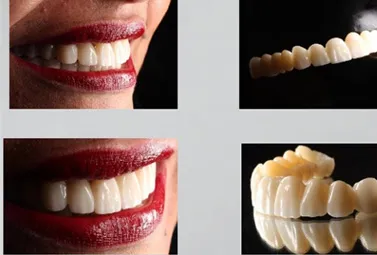

Perfect simulation of natural teeth.

3D Plus Zirconia achieves three-dimensional natural gradients of color, transparency and strength.

3D Plus Zirconia improves the quality of all-ceramic dentures while being as natural and realistic as real teeth.

reating natural aesthetic front tooth restorations

Strong and wear-resistant, natural color, function and aesthetics, long-lasting as before.

High-end natural aesthetics

Transparency gradually decreases from the incisal edge to the neck (57%-43%), reaching the true transparency of natural enamel at the incisal edge, while the lower transparency at the neck effectively masks the underlying color, and the strength of the incisal end gradually decreases, allowing for limited protection of the opposing teeth.

Gradient multi-layer structure design

Adopting 7-layer structure with 11-layer gradient color matching technology to realize the natural integration from functional area to aesthetic area, which is not only durable but also visually coordinated.

A delicate balance between mechanics and aesthetics

Honchon 3D Plus zirconia is designed to be “strong but natural”, ensuring that the color gradation and clarity of the tooth itself is preserved while carrying heavy biting forces.

Strength decreases from cervical to incisal edge (1200-750 MPa), while clarity increases from 45% to 57%, balancing strength with visual realism.

Support layer

The cervical area has higher hardness and flexural strength, ensuring that it is not easy to break after long time use, and is suitable for high intensity wear areas.

Cushioning layer

The smooth transition in the middle area effectively disperses occlusal stress, improves the stability of the restoration and enhances the natural transition effect.

Functional aesthetic layer

The hardness of the area near the incisal edge is moderate, avoiding abrasion of the tooth tip, and presenting a moderate transparency, similar to natural tooth enamel.

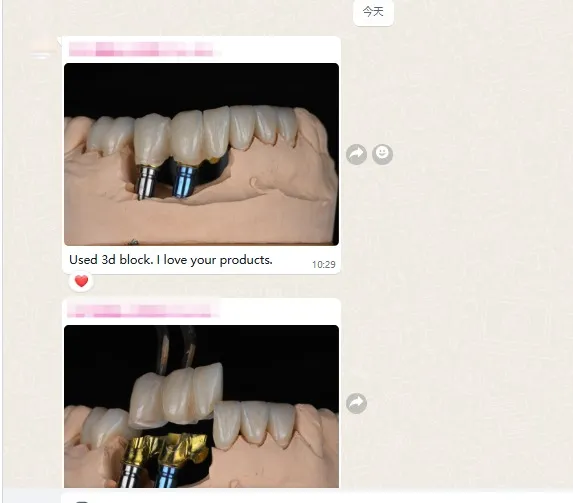

Wide range of applications for a variety of restorative needs

Suitable for single crowns, multi-unit bridges and half-mouth restorations. Compatible with a variety of CNC equipment and processing systems to meet the individualized treatment plans of different patients.

Posterior

Long bridges

Full-mouth restorations

6 bridge units and more

Sintering curve of 3D multilayer zirconia

| 3D Plus Multilayer Sintering Curve | ||||

| Sintering step | Start Temperature(℃) | End Temperature(℃) | Time(Min) | Rate(℃/Min) |

| Step 1 | 20 | 300 | 70 | 4 |

| Step 2 | 300 | 1000 | 175 | 4 |

| Step 3 | 1000 | 1500 | 167 | 3 |

| Step 4 | 1500 | 1500 | 120 | 0 |

| Step 5 | 1500 | 800 | 140 | -5 |

| Step 6 | 800 | natural cooling 20 | / | / |

Cases & Feedback

.jpg)