1. What is ST Multilayer Zirconia Block?

ST Multilayer Zirconia Block is a high-performance dental material designed for use in the fabrication of dental restorations. It features a unique multilayered structure that offers varying levels of translucency and strength. This material mimics the natural appearance of teeth, with a smooth gradient of color, making it ideal for both anterior and posterior restorations. The pre-shaded design reduces the need for additional staining or coloring, saving time for dental professionals.

2. Advantages of ST multilayer zirconia blocks

Natural beauty: ST multilayer zirconia blocks are made of 4Y zirconia powder with multi-layer dry-pressing process, which can make the smooth gradation of transparency and strict adherence to the VITA 16 color scale, presenting an aesthetics that is very close to that of natural teeth.

Superior Strength: ST Zirconia blocks have an impressive strength of over 1100 MPa, far exceeding the 800 MPa flexural strength of zirconia dentures, making them ideal for front and back restorations.

Ease of use: The pre-colored block process minimizes the need for additional color adjustments, simplifies the restorative process, and provides very uniform coloration.

Wide range of applications: Ideal for crowns, bridges, veneers and implants, it is a very versatile zirconia block that is very affordable compared to the expensive 4D PRO zirconia blocks, which are very popular with our customers.

3. Material of ST Multilayer Zirconia Block

| Component | ST Multilayer |

|---|---|

| ZrO2 + HfO2 + Y2O3 | ≥98% |

| Fe2O3 | <0.3% |

| Pr2O3 | <0.2% |

| Er2O3 | <1.0% |

| Other Oxides | <0.5% |

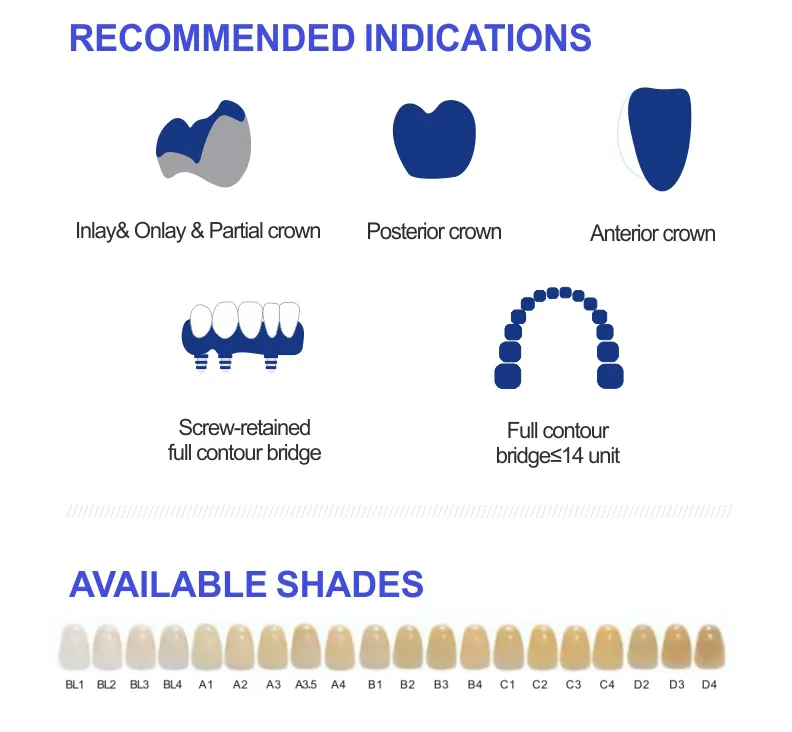

4. Application of ST Multilayer Zirconia Block

Anterior Restorations:

Posterior Restorations:

Veneers

Full Zirconia Crowns and Bridges:

Implant Restorations

5. Sintering Curve of ST Multilayer Zirconia Block

| ST Multilayer Sintering Curve | ||||

| Sintering step | Start Temperature(℃) | End Temperature(℃) | Time(Min) | Rate(℃/Min) |

| Step 1 | 20 | 300 | 70 | 4 |

| Step 2 | 300 | 1000 | 175 | 4 |

| Step 3 | 1000 | 1530 | 177 | 3 |

| Step 4 | 1530 | 1530 | 120 | 0 |

| Step 5 | 1530 | 800 | 146 | -5 |

| Step 6 | 800 | natural cooling 20 | / | / |

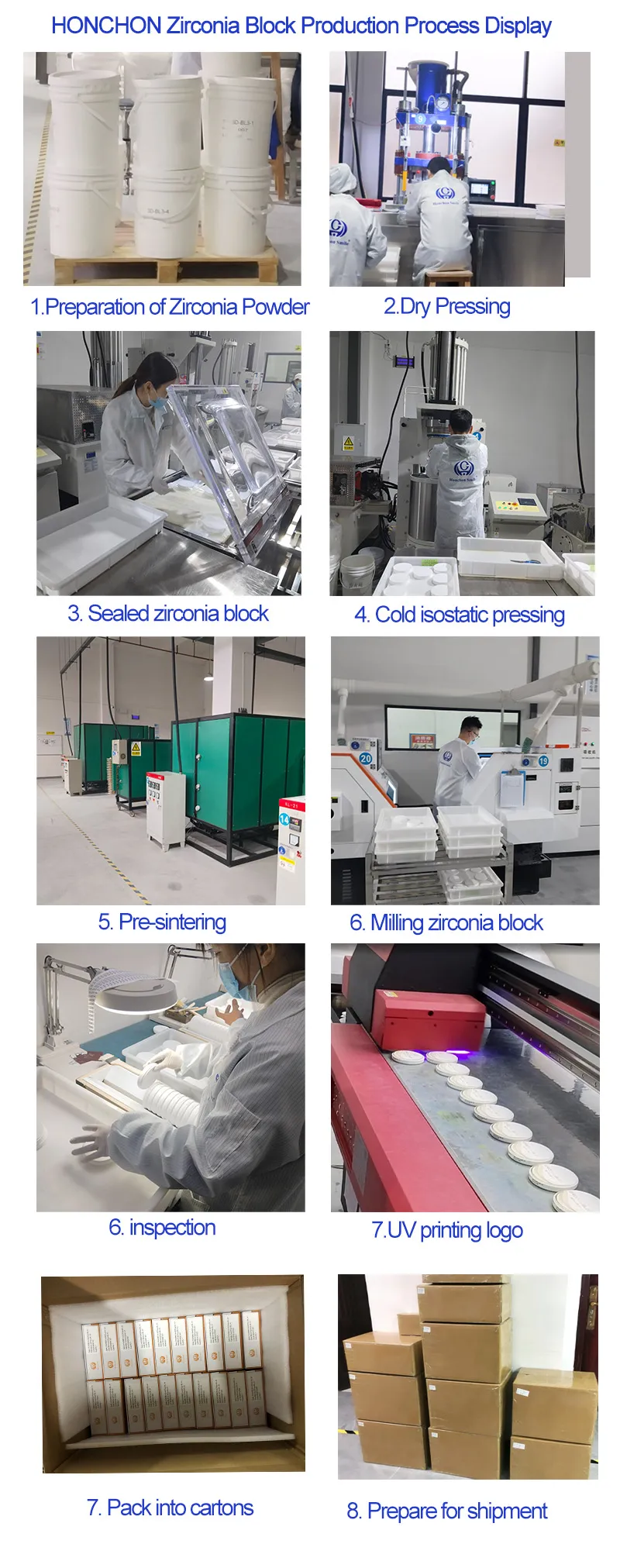

6. Production process of ST multilayer zirconia blocks (key processes)

Selection and mixing: We only use the highest quality zirconia from China, and put the raw materials into the equipment and mix them thoroughly according to the process requirements of ST multilayer.

Dry pressing: zirconia powder is precisely pressed and molded into cylindrical blanks.

Cold Isostatic Pressing: Seal the blank block with sealing tape, plus cling film to repeat the sealing, 2-fold sealing with sufficient redundancy design, put it into the isostatic pressing equipment and press it for 8 minutes to press molding to ensure its density and quality uniformity.

Pre-sintering: the blank blocks are sintered in a sintering furnace for 4 days at 1050 degrees Celsius with precisely controlled rate heating to achieve initial strength for subsequent milling.

Full Inspection: Includes measurement of shrinkage and rigorous testing of the block to ensure consistency in color, strength and...

UV Printing: After full inspection and milling, put into the printer to print the logo.

Packing: Put the products into cartons, packaged and ready for shipment.

7. How to work with us

1. Contact us at Use the form below or email us at luis@honchon.com.

2. Product Inquiry: Communicate the quantity and price of products.

3.Order Confirmation: Confirm the quantity of the products, delivery method and start the production.

4.Delivery and Support: Shipment

8. Our Certifications

We are committed to providing high-quality dental products and hold certifications that meet international standards.

CE Certification: Meets European health and safety standards.

FDA: Approved for use in dental procedures in the United States.

ISO 13485: Medical device management system certification.

9. Our factory

Our factory is equipped with the most advanced production technology in the industry. Our employees are dental technicians and material engineers, who are excellent scientific and technological talents in the industry. We have more than 8,000 square meters of modern factory buildings, with a peak output of more than 100,000 per month and sufficient inventory. Please contact us for free samples and quotes.

.jpg)