Honchon® 4D Multi Layer Zirconia Disc

Natural Gradient · High Strength · Seamless Aesthetics

The Honchon® 4D Multi Layer Zirconia Disc is the flagship zirconia product developed by Changsha Honchon Technology. Using China’s finest zirconia powder, and manufactured with fully imported isostatic pressing equipment, every disc is produced with our proprietary formula and rigorous quality control process. Since launch, it has been widely praised and adopted by dental professionals around the world, earning us many long-term clients.

Features OF 4D Multi layer zirconia disc

Safety

Safety

Non-irritating and corrosion-resistant

Excellent biocompatibility – safe for intraoral use

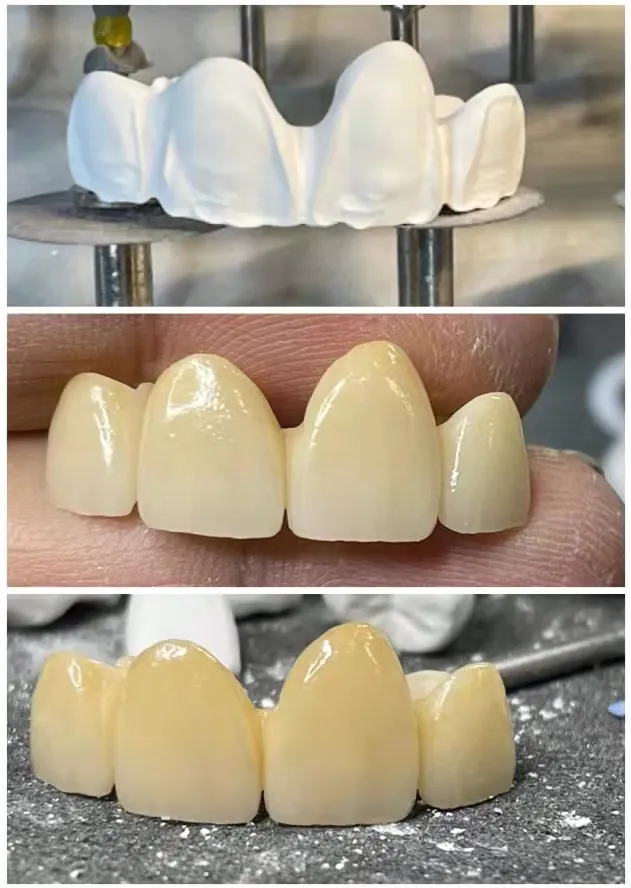

Natural Aesthetics

Mimics the natural gradient of real teeth

Six layers of varying translucency for seamless transition

No visible layer lines after sintering

High Comfort

Low thermal conductivity

Reduces pulp sensitivity caused by temperature fluctuations

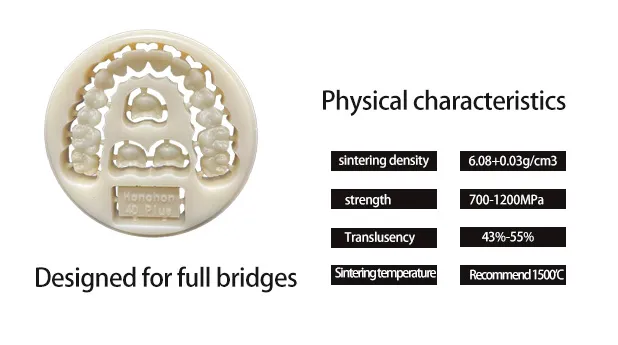

Strength & Durability

Flexural strength exceeds 1200 MPa

Suitable for both aesthetic and functional zones

Long-term performance and wear resistance

application OF 4D Multi layer zirconia disc

Inlay& Onlay & Partial crown

Screw-retained full contour bridge

Posterior crown

Anterior crown

Full contour bridges14 unit

Six-layer gradient design with progressive translucency

Natural shade transition from cervical to incisal

Enhanced light reflection and depth

Ideal for both anterior and posterior zones

Available sizes of 4D Multi layer zirconia disc

Opening system | Amann Girrbach system | ZirkonZahn system |

98*10mm | 89*71*10mm | 95*10mm |

98*12mm | 89*71*12mm | 95*12mm |

98*14mm | 89*71*14mm | 95*14mm |

98*16mm | 89*71*16mm | 95*16mm |

98*18mm | 89*71*18mm | 95*18mm |

98*20mm | 89*71*20mm | 95*20mm |

98*22mm | 89*71*22mm | 95*22mm |

98*25mm | 89*71*25mm | 95*25mm |

Sintering curve of 4D Multi layer zirconia disc

| Sintering Curve | ||||

| Sintering step | Start Temperature(℃) | End Temperature(℃) | Time(Min) | Rate(℃/Min) |

| Step 1 | 20 | 100 | 27 | 3 |

| Step 2 | 100 | 1000 | 150 | 6 |

| Step 3 | 1000 | 1000 | 10 | 0 |

| Step 4 | 1000 | 1500 | 100 | 5 |

| Step 5 | 1500 | 1500 | 120 | 0 |

| Step 6 | 1500 | natural cooling20 | / | / |

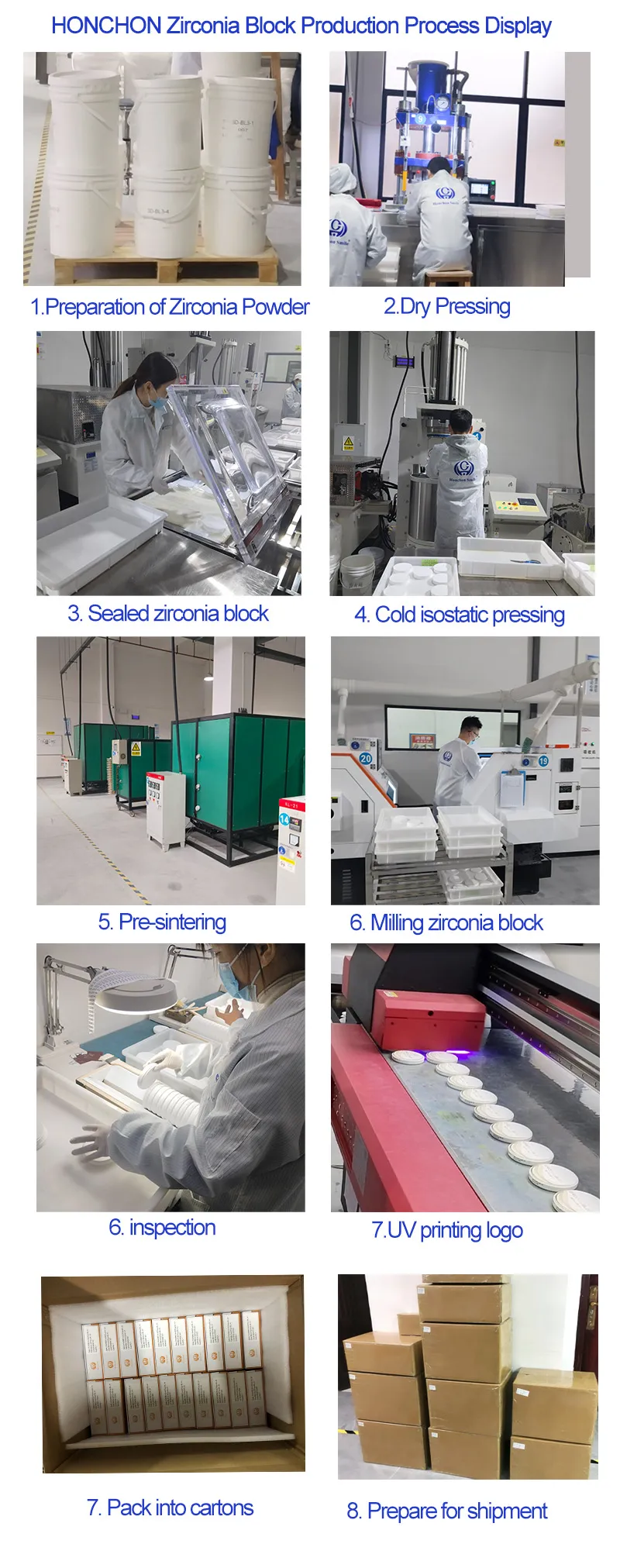

Manufacturing Process of 4D Multi Layer Zirconia Disc

Each Honchon® zirconia disc is the result of a meticulous multi-stage production process, ensuring precision, durability, and consistency.

Powder Loading

High-purity zirconia powder, specifically formulated for dental applications, is carefully loaded into the equipment. Only premium-quality powder is used to ensure stability and safety.

Pre-Pressing (Shaping)

The powder is compressed into a preliminary shape to ensure uniformity and optimal compaction, preparing it for densification.

Cold Isostatic Pressing

The shaped powder is placed into a mold and pressed from all directions using cold isostatic pressure. This step ensures maximum material density and homogeneity.

Pre-Sintering

The discs are heated at controlled temperatures to partially fuse the zirconia particles. This increases strength and makes them ready for machining.

Milling & Shaping

The pre-sintered blanks are precisely milled using advanced CAD/CAM technology to achieve accurate contours and dimensions.

Inspection & Packaging

Each disc undergoes thorough quality control to ensure consistency in shade, shape, and performance. After inspection, they are securely packaged to prevent damage during transportation.

Cases & Feedback

.jpg)