High Strength Multilayer Zirconia Disk

Experience Exceptional Durability and Aesthetics with Our High Strength Multilayer Zirconia Disks!

1. Advantages and Highlights of High Strength Multilayer Zirconia Disk

- Superior Strength: Our zirconia disks boast a bending strength of 1000 MPa, ensuring they can withstand the rigors of dental applications.

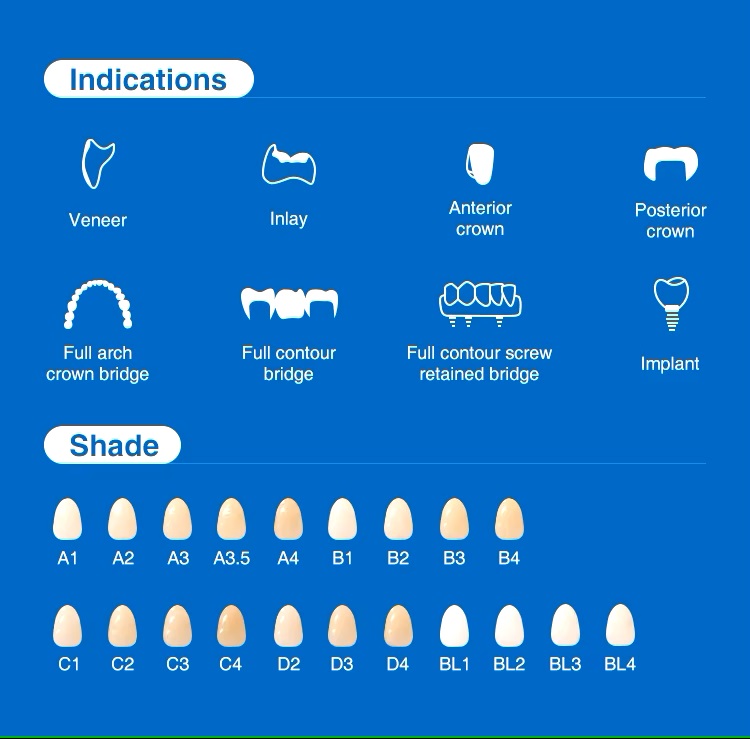

- Natural Aesthetics: Available in a wide range of Vita 16 colors plus BL1, BL2, and BL3, these disks mimic the appearance of natural teeth.

- Excellent Translucency: With a light transmittance of 46%, our ultra-translucent disks provide a beautiful aesthetic that enhances dental restorations.

High Density: Featuring a sintered density of 6.0 g/cm³, they offer enhanced durability and performance.

2. Parameters of High Strength Multilayer Zirconia Disk

- Colors: Vita 16 color + BL1/BL2/BL3

- Light Transmittance: 46%

- Sintering Temperature: 1500℃

- Product Type: Multilayer zirconia

- Aesthetic: Ultra translucent

- Sintered Density: 6.0 g/cm³

- Bending Strength: 1000 MPa

- Model Numbers: OD98 / OD95 / AG 92*75

Product Sizes: 10mm, 12mm, 14mm, 16mm, 18mm, 20mm, 22mm, 25mm

3. Applications of High Strength Multilayer Zirconia Disk

These disks are ideal for:

- Dental crowns and bridges

- Inlays and onlays

- Full contour restorations

Any application requiring high strength and aesthetic appeal

4. Pricing Information

Our High Strength Multilayer Zirconia Disks are custom-made with tiered pricing. For a quote tailored to your needs, please contact us via WhatsApp at +8613055185196 or send us an email.

5. Production Process of High Strength Multilayer Zirconia Disk

The production process includes:

- Material Selection: We use high-quality zirconia powder to ensure optimal performance.

- Cold Isostatic Pressing: The zirconia powder is pressed to form uniform disks.

- Sintering: Disks are sintered at 1500℃ to achieve desired strength and density.

Quality Control: Each batch undergoes thorough testing to ensure it meets industry standards.

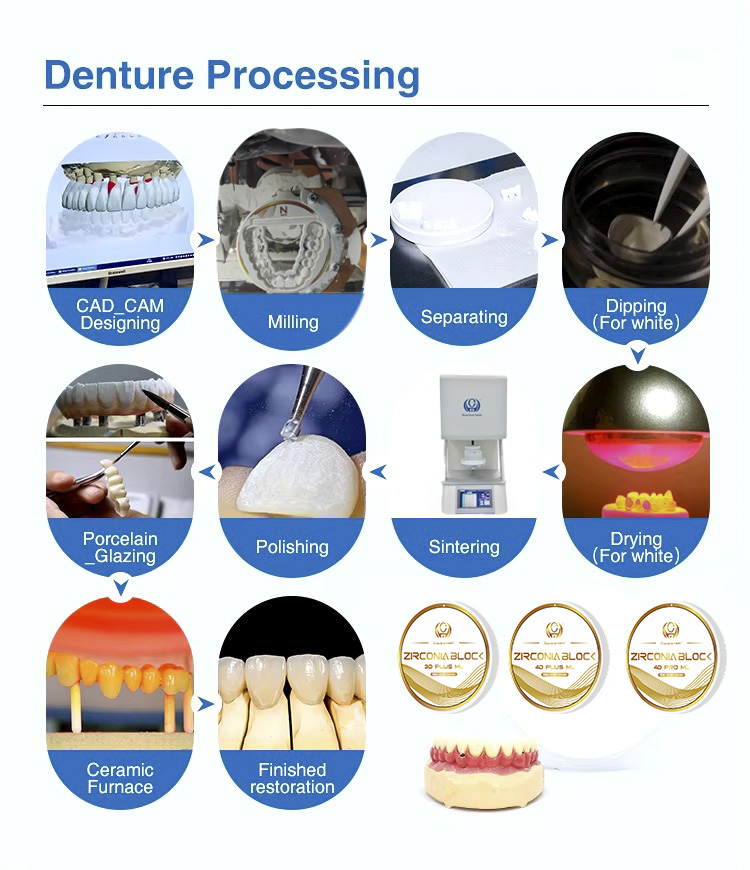

6. Fabrication of Dental Restorations from High Strength Multilayer Zirconia Disk

The process involves:

- Design: A digital model of the restoration is created using CAD/CAM technology.

- Milling: The zirconia disk is milled into the required shape.

- Sintering: The milled restoration is sintered for enhanced durability.

Finishing: Final adjustments and polishing are made for optimal aesthetics and fit.

7. Our Manufacturing Advantage

As a manufacturer, we can customize the zirconia disks to fit your specifications, including logo and packaging options. Our commitment to quality and innovation ensures you receive reliable products tailored to your needs.

For more information about our High Strength Multilayer Zirconia Disks or to request a sample, please contact us. We are here to support your dental material needs!

Cases & Feedback

.jpg)