1. What is Dental Zirconia Blank?

Dental zirconia blank is a high-performance ceramic material used in the fabrication of dental restorations. It consists mainly of zirconia, yttrium oxide, which is pre-sintered to facilitate carving, but also presents excellent strength and aesthetics after sintering. Whether it is a single crown, a bridge, or a full mouth restoration, dental zirconia blanks are up to the task. Changsha Honchon Technology Co., Ltd. has been specializing in the field of dental zirconia for 14 years, and is committed to providing stable and reliable dental materials to customers around the world!

2. Advantages of Dental Zirconia Blank:

High strength and fracture resistance: the sintered zirconia blanks have extremely high mechanical properties and are suitable for all types of loaded area restorations.

Excellent aesthetic effect: the choice of different transmittance rates can meet the aesthetic requirements of different areas from anterior to posterior teeth.

Good biocompatibility: highly compatible with human tissues, reducing allergies and rejection reactions.

Wear-resistant and corrosion-resistant: maintains a good surface condition under long-time use.

Convenient processing: adaptable to various CAD/CAM systems, high processing efficiency.

3. Material of Dental Zirconia Blank

HONCHON dental zirconia blanks are made from the best high-purity zirconia powder (sinocera) in China, and the ingredients are strictly controlled to ensure the stability and consistency of the material. The main chemical composition is as follows:

| Composition | Content |

|---|---|

| Zirconia and stabilizers (ZrO₂ + Y₂O₃ + HfO₂ + Al₂O₃) | ≥ 99.0% |

| Yttrium oxide (Y₂O₃) | 4.0% – 10.0% |

| Hafnium oxide (HfO₂) | ≤ 5% |

| Aluminum oxide (Al₂O₃) | ≤ 0.1% |

| Other oxides (Fe₂O₃, Er₂O₃, MnO) | ≤ 0.9% |

The precise control of chemical composition ensures that Honchon zirconia blanks achieve excellent density, aesthetics, and mechanical properties after sintering, making them ideal for a wide range of dental restoration applications.

4. Application of Dental Zirconia Blanks

Dental zirconia blanks are widely used for various types of restorations, depending on their translucency, strength, and aesthetic requirements.

Honchon offers a full range of zirconia blanks designed for different clinical applications, from posterior crowns to full-contour esthetic bridges.

Here is a quick overview of our product types and their recommended applications:

| Product Type | Translucency | Strength | Color | Recommended Main Application |

|---|---|---|---|---|

| HT plus | 40% | 1350 MPa | White | Posterior & long bridge |

| ST plus | 43% | 1200 MPa | White | Posterior & bridge |

| SHT | 46% | 1000 MPa | White | Posterior, anterior & bridge |

| UT | 49% | 650 MPa | White | Anterior |

| HTC | 40% | 1350 MPa | 16 shades | Posterior & long bridge |

| STC | 43% | 1100 MPa | 16 shades | Posterior & bridge |

| UTC | 49% | 650 MPa | 16 shades | Anterior |

| STML | 43% | 1100 MPa | 16 shades | Full contour & bridge |

| SHTML | 46% | 1100 MPa | 16 shades | Full contour & bridge |

| UTML | 49% | 650 MPa | 16 shades | Anterior |

| 3D-Plus ML | 45%–57% | 1050–700 MPa | 16 shades and BL | All |

| 4D-Plus ML | 43%–55% | 1200–700 MPa | 16 shades and BL | All |

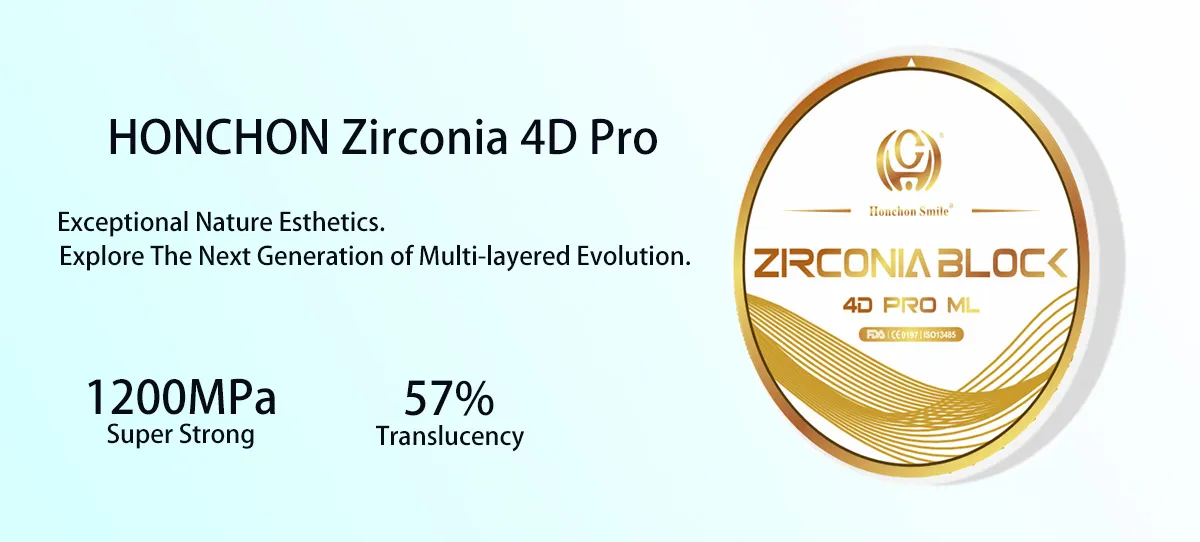

| 4D-PRO ML | 43%–57% | 1200–750 MPa | 16 shades and BL | All |

Each product is carefully designed to meet specific clinical needs:

High-strength zirconia like HT plus and HTC is ideal for posterior crowns and long-span bridges.

Medium-translucency options like ST plus, STC, and STML balance strength and esthetics, perfect for posterior and bridgework.

High-translucency materials like UT, UTC, UTML, and multi-layered types (3D-Plus ML, 4D-Plus ML) are excellent for anterior restorations and full-contour cases where natural appearance is key.

At Honchon, we help you find the right zirconia solution for every case.

5. Sintering Curve of Dental Zirconia Blank

Different types of zirconia blanks have different optimal sintering curves. The following sintering parameters are generally recommended:

Heating phase: from room temperature to 900°C at 5-8°C per minute.

Holding phase: hold at 900°C for 30 minutes to release stresses

Rise to final temperature (e.g. 1500°C) and hold for a further 2 hours.

Natural cooling to room temperature

For specific sintering procedures, Honchon will include detailed recommendations depending on the model to help the customer obtain the best sintering results.

6. Process of Dental Zirconia Blank (description of key steps)

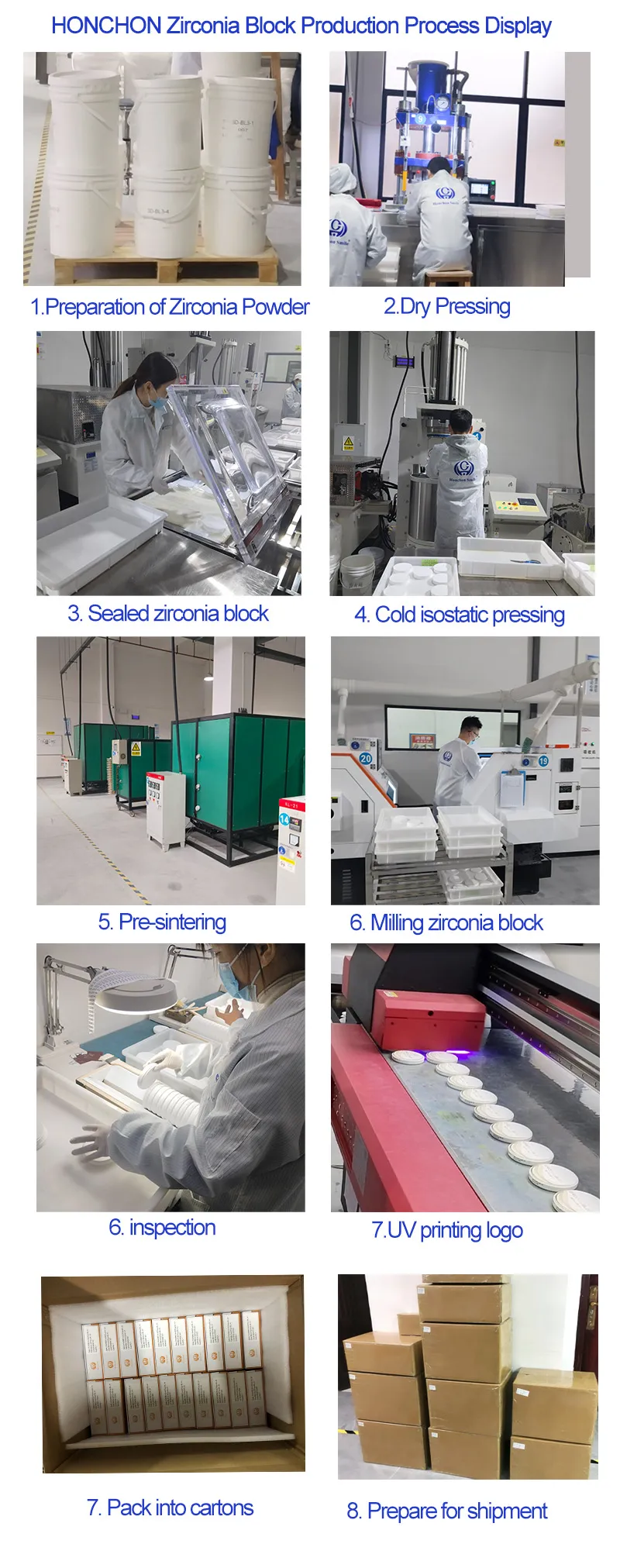

The production process of Honchon Zirconia Blank consists of:

1. Preparation of raw materials, according to the zirconia composition table, the raw materials are poured into the mixing equipment and stirred evenly.

2. Dry pressing, add the stirred powder according to the weight table of zirconia blanks into the dry pressing equipment and press it into cylindrical blank shape.

3. Isostatic pressing: Seal the zirconia blanks, put them into the isostatic pressing equipment and press them for 8 minutes.

4. Pre-sintering: Put the zirconia blanks into the pre-sintering kiln at 1050 degrees Celsius and pre-sinter them for 4 days.

5. Milling: Zirconia blanks are milled to specific size and thickness according to the specified dimensions.

6. Inspection: The zirconia blanks are strictly inspected according to the operation instructions.

7. Packing: Pack the zirconia blanks ready for shipment.

7. How to Cooperate with Us

We support a variety of cooperative models:

Standard product purchasing: you can choose Honchon's existing series products with fast delivery.

OEM/ODM customized cooperation: according to your brand and needs, customized zirconia blank specifications, labels, packaging, etc..

Agent Distribution: Welcome to be Honchon's authorized agent in each region to develop the market together.

8. Our Certifications

Honchon has passed ISO 13485 medical device quality management system certification, and our products comply with CE and FDA standards. We always insist on high standard management, from source to finished product to ensure the safety and stability of each piece of zirconia blank .

9. Our Factory

Honchon factory is located in Changsha Wangcheng Economic Development Zone with beautiful environment and convenient transportation, with modern production workshop and advanced manufacturing equipment.

Floor space: 8000 square meters

Production Line: Fully automated powder processing and molding line.

Team members: senior R&D engineers and dental technicians in the industry.

We believe that a good production environment, excellent talent pool and stable supply chain management system are the important guarantee for stable quality.

10. Dental Zirconia Blank Packaging

Honchon uses special shock-resistant packaging. Each zirconia blanks is individually protected and comes with detailed product labels and sintering instructions. The outer box is thickened to ensure the safety of the product during long-distance transportation.

.jpg)