1. Product Specifications and Technical Parameters

Detailed Technical Parameters

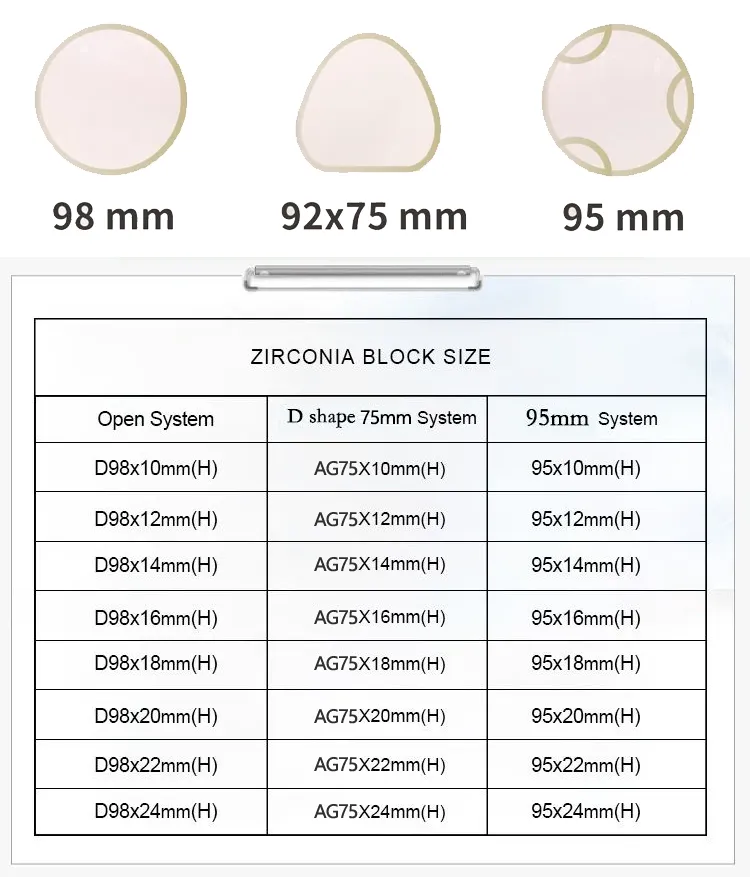

Our pre-sintered zirconia blocks are meticulously crafted with precision and consistency. We offer a range of sizes to cater to diverse needs, with specific material compositions that ensure optimal performance. The blocks feature a high hardness level and impressive compressive strength, making them ideal for various dental applications. Additionally, their translucency is carefully calibrated to match natural tooth aesthetics, providing a balance of strength and beauty.

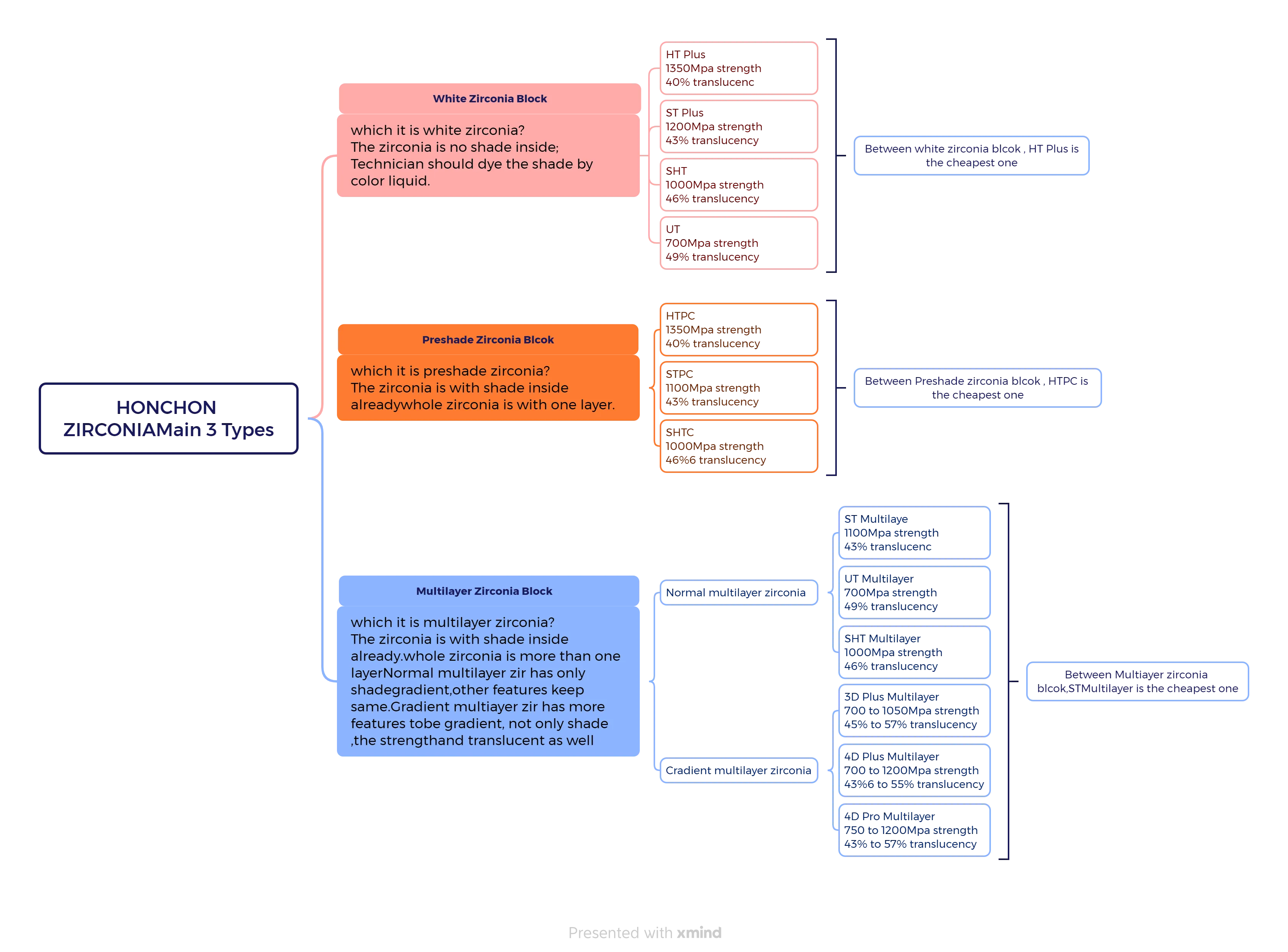

White Zirconia Block

HT Plus1350Mpa strength 40% translucency

ST PIus1200Mpa strength,43% translucency

SHT1000Mpa strength,46% translucency

UT700Mpa strength,49% translucency

Preshade Zirconia Blcok

HTPC 1350Mpa strength, 40%translucency

STPC 1100Mpa strength,43% translucency

SHTC 1000Mpa strength,46% translucency

Normal multilayer zirconia

ST Multilayer 1100Mpa strength,43% translucency

UT Muitilayer 700Mpa strength,49% translucency

SHT Multilayer 1000Mpa strength,46% translucency

Gradient multilayer zirconia

3D Plus Multilayer 700 to 1050Mpa strength,45% to 57% translucency

4D Plus Multilayer 700 to 1200Mpa strength,43%to 55% translucency

4D Pro Multilayer 750 to 1200Mpa strength,43%to 57% translucency

Product Standards and Certifications

To ensure the highest quality, our zirconia blocks are produced to industry-leading standards. We have certifications such as ISO and CE, FDA, etc., which prove the reliability and safety of our products. These certifications are essential to build trust with our B2B customers, assuring them that our products meet international quality benchmarks.

2. Application Scenarios

Applicable Industries and Use Cases

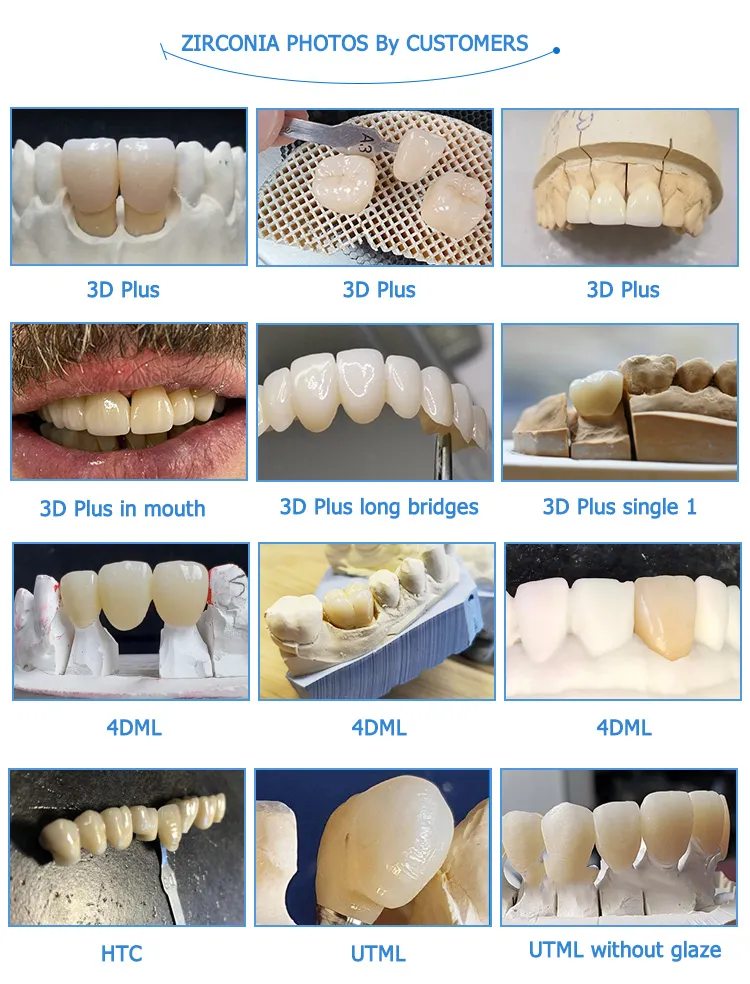

The dentistry sector makes extensive use of our pre-sintered zirconia blocks, particularly in the fabrication of crowns, bridges, and other treatments. They are made to address particular problems, such preserving durability and producing a natural look. Dental clinics and laboratories that strive to give patients high-quality restorations can use these blocks.

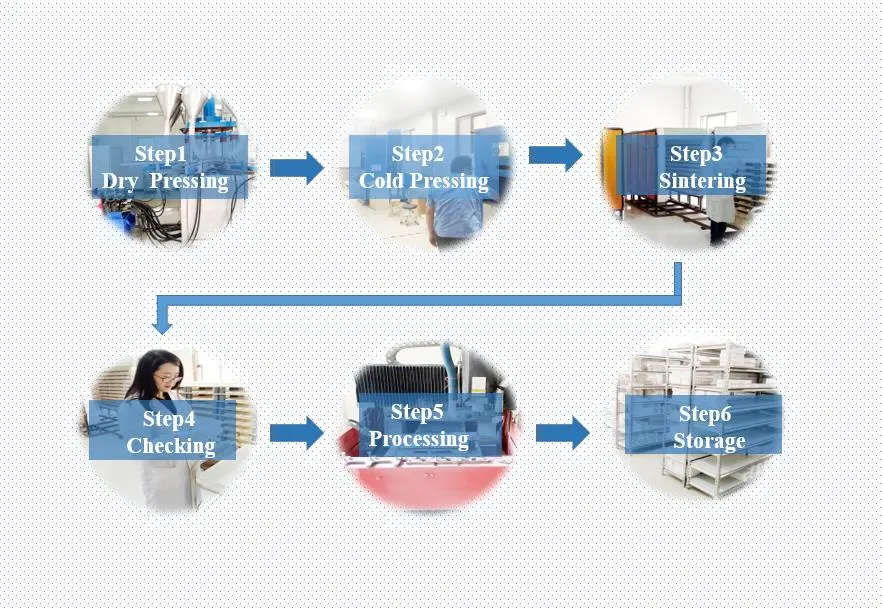

3. The Manufacturing Process and Quality Control

Synopsis of the Manufacturing Process

Strict quality control procedures and cutting-edge technologies underpin our manufacturing process. We maintain consistency and great performance by monitoring every stage of the process, from the selection of raw materials to the final inspection. We utilize the best zirconia powder available in China. To create zirconia blocks that satisfy the highest industry standards, we employ the pre-sintering and cold isostatic pressing processes that are leaders in the industry, CIP.

Test results and quality inspection reports

We offer thorough quality inspection reports for each batch of zirconia blocks that we produce. These papers contain comprehensive test findings that attest to the consistency, stability, and industry standard compliance of our product. We instill trust in our B2B clients regarding the dependability of our zirconia blocks by offering these reports.

Procedure for Ordering

To make ordering simple and effective for our customers, we have shortened the procedure. There are comprehensive guidelines explaining how to place an order, as well as the various payment options, delivery windows, and minimum purchase amounts. Our customers are able to make judgments about purchases with confidence and speed thanks to this efficient approach.

5. Technical assistance and after-sale service

Guaranteed after-sale

We offer thorough after-sales service plans to support the quality of our products. Generous warranty durations, unambiguous rules for returns and exchanges, and trustworthy repair services are all part of these programs. Our intention is to provide B2B clients with the assurance that any problems will be handled efficiently and promptly.

Technical Assistance

Our technical support staff is available at all times to assist clients in resolving any issues they may run into. We provide several ways to get help, including online chat, email, and phone. Furthermore, we offer comprehensive technical documentation and user manuals to assist clients in making the most of our zirconia blocks.

6. Capabilities for Supply Chain and Delivery

Capabilities for Production and Delivery

Our robust production and delivery capabilities are something we take great pleasure in. Our facility is equipped to handle large-scale orders, and we can make 60,000 pre-sintered zirconia blocks each month, so we can satisfy even the pickiest clients. Regardless of the size of the purchase, we guarantee quick delivery by optimizing our supply chain and maintaining appropriate inventory levels. Standard products are sent within 1-2 working days, and large-volume orders are negotiated based on the specific order circumstances.

Worldwide Transportation and Storage Solutions

We can organize air, sea, and land transportation as well as global logistics and distribution services since we recognize the value of dependable delivery, particularly for our global clientele.

7. Organizational Change and Sector Position

Overview of the Company

We at Honchon, with our many years of experience in the dental materials sector, have emerged as China's top manufacturer of zirconia blocks. Our reputation among B2B clients worldwide has been built on our dedication to quality and innovation. In an effort to provide our clients with greater service, we are constantly working to enhance our offerings.

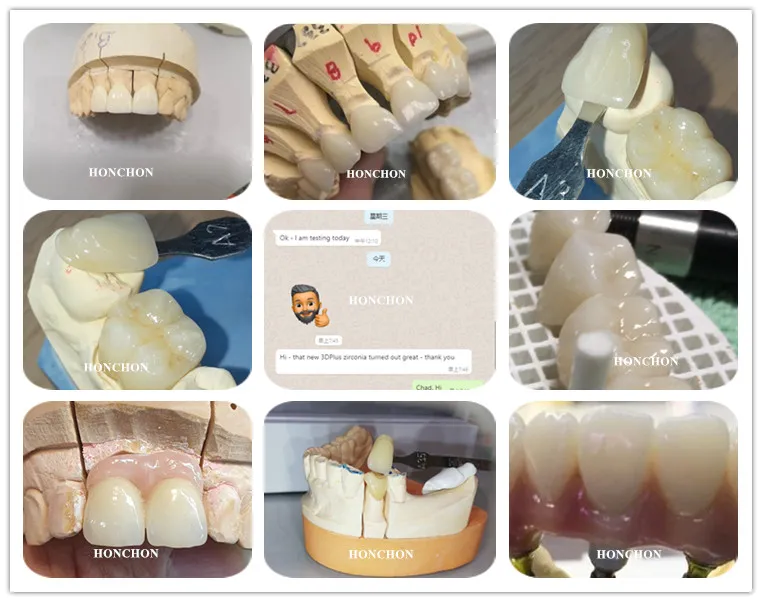

Client Testimonials and Comments

We cherish client input and take great pride in showcasing the glowing testimonials we get. These endorsements from other business-to-business clients demonstrate the caliber of our offerings and the dependability of our services, fostering confidence among prospective clients.

.jpg)