High Strength Zirconia Discs – Honchon Smile

Why Choose Honchon Smile?

Honchon Smile is a trusted name in the dental materials industry, specializing in the production of high-strength zirconia discs. With over a decade of manufacturing experience, advanced technology, and a commitment to quality, we provide solutions tailored to meet the evolving needs of dental professionals worldwide.

Our Advantages

- Premium Quality Zirconia: Manufactured using the finest zirconia powders from Japan (TOSOH) and China’s leading suppliers.

- Cutting-Edge Technology: Utilizes cold isostatic pressing and pre-sintering processes for optimal uniformity and strength.

- Customizable Options: A wide range of sizes, thicknesses, and colors to suit various dental restoration needs.

- Global Expertise: Products exported to over 120 countries, trusted by dental clinics, labs, and distributors globally.

- Fast Delivery: Ready-to-ship stock for standard products ensures lead times of 1-3 business days.

Comprehensive Support: 24/7 online assistance and a 5-year product warranty.

What Are High Strength Zirconia Discs?

High-strength zirconia discs are dental-grade materials designed for creating durable and aesthetic dental restorations. These discs are widely used in CAD/CAM milling systems for applications ranging from crowns and bridges to custom abutments. Their unique balance of strength and translucency makes them ideal for both anterior and posterior restorations.

Product Features and Advantages

Key Features

- Unmatched Strength: Boasting a bending strength of 1350 MPa, these discs are perfect for long-span bridges and posterior crowns.

- High Translucency: Aesthetic solutions for anterior restorations without compromising durability.

- Stable Milling Performance: Ensures smooth milling, reduces chipping, and extends the life of milling tools.

- Optimized Grain Structure: Uniform composition for superior polishability and long-lasting results.

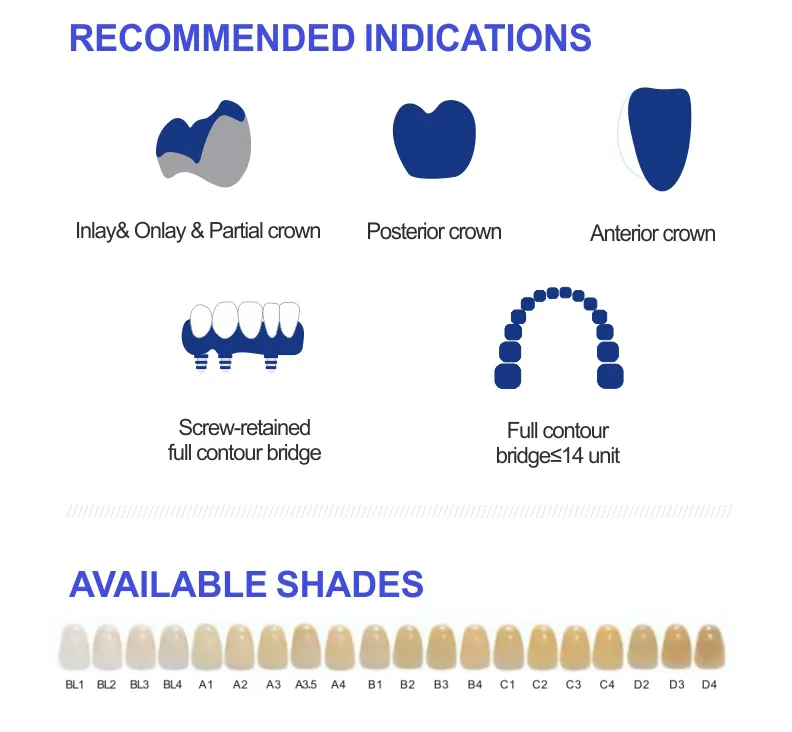

- Wide Color Compatibility: Pre-shaded options available in VITA 16 shades and 4 additional popular shades.

Product Benefits

- Versatility: Suitable for multiple dental restorations, meeting diverse clinical needs.

- Time Efficiency: Pre-shaded discs reduce manual staining and save processing time.

- Eco-Friendly: Manufactured with minimal waste and environmental impact.

- Cost-Effective: High durability reduces the need for replacement, saving costs for dental professionals.

Physical Parameters

| Attribute | Specification |

|---|---|

| Color | White |

| Aesthetic | High Translucent Plus |

| Sintered Density | 6.0g/cm³ |

| Bending Strength | 1350 MPa |

| Light Transmittance | 40% |

| Sintering Temperature | 1530°C |

| Available Thicknesses | 10mm, 12mm, 14mm, 16mm, 18mm, 20mm, 25mm |

Applications of High Strength Zirconia Discs

High-strength zirconia discs are designed for a wide range of dental restorations, offering versatility and reliability in the following applications:

- Inlay & Onlay Restorations: Durable and aesthetic solutions for minor tooth damage.

- Crowns: Ideal for both anterior and posterior crowns, providing high strength and natural aesthetics.

- Bridges: Suitable for long-span bridges, withstanding high chewing forces.

- Custom Abutments: Perfect for implant-supported restorations.

Full Contour Restorations: Excellent for monolithic restorations requiring high polishability.

Craftsmanship & Manufacturing Process

- Material Selection: Premium zirconia powders from China’s top suppliers.

- Cold Isostatic Pressing: Achieves uniform density for superior strength.

- Pre-Sintering: Enhances machinability while maintaining material integrity.

- Precision Milling: Ensures accurate and consistent dimensions.

Strict Quality Control: Multiple inspection stages to meet international certifications.

How to Maintain High Strength Zirconia Discs

- Proper Storage: Keep discs in a dry, temperature-controlled environment.

- Careful Handling: Avoid dropping or exposing discs to excessive pressure before milling.

- Regular Maintenance: Ensure milling tools and sintering equipment are well-maintained for optimal results.

- Follow Sintering Guidelines: Use the recommended sintering temperature (1530°C) to ensure material integrity.

How to Cooperate With Us

- Inquiry: Contact our team with your specific needs.

- Customization: Select from our wide range of sizes, colors, and specifications.

- Production: Once confirmed, we start manufacturing using our state-of-the-art equipment.

- Shipping: Products are securely packed and shipped to your location.

- Support: Enjoy ongoing technical support and warranty services.

Certifications

- ISO 13485: Ensures compliance with medical device quality management systems.

- CE Certification: Guarantees adherence to European safety standards.

FDA Approval: Meets the stringent requirements of the U.S. Food and Drug Administration.

Our Factory

Our 8,000-square-meter facility is equipped with the latest machinery and managed by a professional team with years of experience. We produce up to 100,000 zirconia blocks monthly to meet the demands of our global clients.

Factory Highlights

- Advanced sintering and milling equipment.

- Dedicated R&D team for innovative solutions.

Rigorous quality control systems.

Customer Cases

- European Distributor: Increased sales by 30% using our pre-shaded zirconia discs.

- Dental Lab in the U.S.: Successfully completed over 5,000 restorations with Honchon Smile products.

- Asia-Pacific Partner: Reduced costs and improved client satisfaction with custom solutions.

FAQ

- What makes your zirconia discs unique?

Our discs combine high strength (1350 MPa) with superior translucency, making them ideal for both anterior and posterior restorations. - Do you offer custom sizes or shades?

Yes, we provide OEM/ODM services to meet your specific requirements. - What is the delivery time for standard products?

Most standard products are shipped within 1-3 business days.

Cases & Feedback

.jpg)