1.What is ST white zirconia block ?

ST white zirconia block is a high-quality, high-performance material widely used in dental restoration. ST is the abbreviation of super transparency. The transparency of ST white zirconia block is usually above 40%. It has the characteristics of high strength, high stability, high transmittance and high biocompatibility. It is one of the most widely used materials in the field of modern dental restoration.

2.Advantages of ST white dental zirconia block dental materials:

1.HONCHON's ST white dental zirconia block has passed China CFDA, CE, ISO certification.

2.HONCHON's ST white zirconia block does not contain any additives, and the purity of yttrium-stabilized zirconia is as high as 99%, which is greener and safer.

3.Our ST white zirconia block is available in ivory color, which is more in line with natural tooth dentin, and the enamel is saturated and transparent.

4.ST white zirconia block has undergone a double pressing process of dry pressing and cold isostatic pressing, and the product's three-point bending strength performance is more excellent and uniform and stable.

5.ST white zirconia block controls the grain size through proprietary technology, making the product's light transmission performance superior.

6.The tunnel-type pre-firing process ensures that the porcelain block has moderate hardness, is easy to cut, and does not collapse.

7.Strict production process control procedures ensure product stability, shrinkage, and consistency.

We have CE certification. Each of our zirconia blocks/blanks is marked with shrinkage rate, which is affixed to the zirconia block product.

Our zirconia blocks/blanks are compatible with different brands of CAD/CAM systems and manual systems, such as Zircon system, Sirona Inlab system, Kavo system, Aman system and Wieland system.

3.Material of ST White Zirconia Block

The ST White Zirconia Block is crafted from a high-purity formula designed to deliver exceptional strength, stability, and translucency for dental restorations.

Material Composition Breakdown:

ZrO₂ + HfO₂ + Y₂O₃ (≥99%): Forms the primary structure, ensuring high strength and durability.

Y₂O₃ (4.5%-6.0%): Acts as a stabilizer, enhancing toughness and crack resistance.

Al₂O₃ (<0.15%): Improves sintering and mechanical performance.

Other Oxides (<0.15%): Maintains homogeneity and quality without impacting translucency.

This precise composition ensures the block meets the high standards required for modern dental applications.

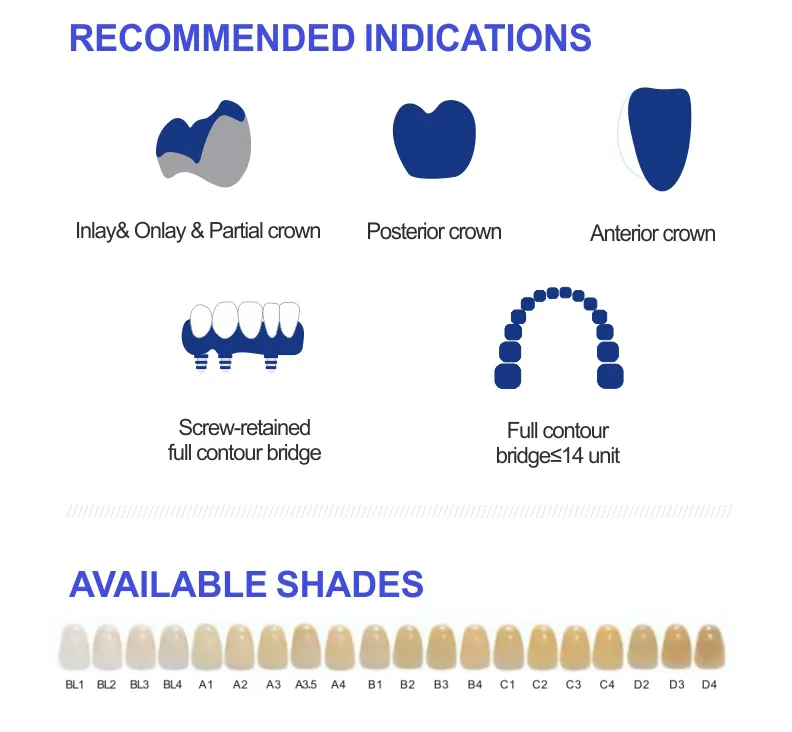

4.Application of st white zirconia block

The ST White Zirconia Block is a versatile material suitable for a wide range of dental applications. ST White Zirconia Block is commonly used in the fabrication of inlays, onlays, and partial crowns, offering precision and durability. For aesthetic needs, it performs exceptionally well in anterior crowns, ensuring natural translucency. Its high strength makes it ideal for posterior crowns, coping, and coping bridges. Additionally, the ST White Zirconia Block is perfect for full contour restorations, including 14-unit bridges, combining excellent mechanical properties with superior aesthetic outcomes.

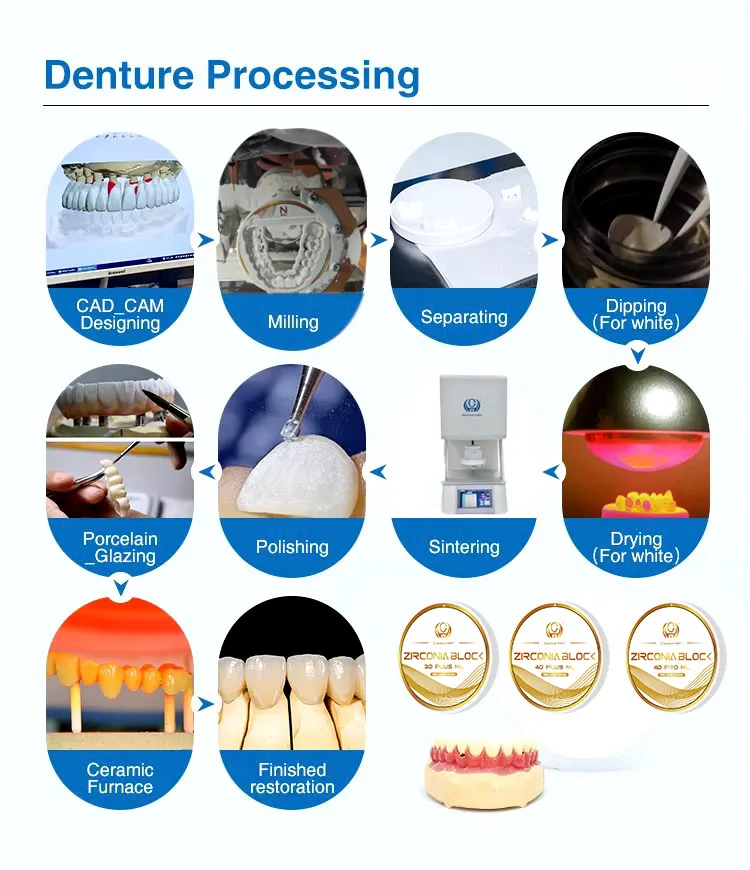

5.Process of ST White Zirconia Block

The manufacturing process of ST White Zirconia Block is streamlined and efficient, focusing on producing high-purity, pre-sintered white zirconia for dental applications. The process includes the following steps:

Powder Preparation: High-quality zirconia-based powders (ZrO₂ with stabilizing agents like Y₂O₃) are carefully selected and prepared to ensure consistent purity and performance.

Mixing and Homogenization: The zirconia powders are thoroughly mixed to achieve a uniform composition, ensuring excellent mechanical properties and a flawless white appearance.

Molding: The homogenized powder is shaped into blanks using cold isostatic pressing (CIP). This method ensures uniform density and reduces the risk of defects in the final product.

Pre-Sintering: The molded blanks are pre-sintered at a controlled temperature to achieve a machinable state while retaining sufficient strength.

Shaping and Cutting: After pre-sintering, the blocks are machined or cut into specific sizes (e.g., 98mm, 95mm, or customized dimensions) to ensure compatibility with various dental milling systems.

This pre-sintered process is designed to deliver durable and precisely shaped ST White Zirconia Blocks that can be further processed in dental labs for high-quality restorations.

6.Best Practices for Handling and Storing ST White Zirconia Blocks

Storage

Keep blocks in a dry, clean, and dust-free environment.

Store at room temperature, away from sunlight and humidity.

Avoid stacking too high to prevent damage.

Handling

Handle with care to avoid cracks or surface damage.

Inspect for defects before use and set aside compromised blocks.

Cleaning

Ensure blocks are free of dust or debris before milling.

Wipe gently with a clean, lint-free cloth if needed.

Milling Preparation

Use a clean, calibrated milling machine.

Ensure the correct tools are used to prevent chipping.

Inspection

Check for chips or imperfections post-milling. Address any issues before proceeding.

General Tips

Avoid exposure to chemicals or harsh cleaners.

Rotate stock to use blocks within their shelf life.

7.How to Cooperate with Us

Working with us is simple and straightforward:

Contact Us: Share your product requirements via email or phone.

Get a Quote: We provide detailed pricing and product information.

Confirm Order: Approve the details, and we’ll start production.

Delivery: Your products are shipped promptly with tracking provided.

After-Sales Support: We’re here to assist with any questions or concerns.

8.Our Certifications

ISO 13485: Medical device quality management system.

FDA Approved: Safe for use in the U.S. market.

CE Certified: Meets EU safety and quality standards.

Our certifications guarantee the reliability and quality of our dental products globally.

9.Our Factory

Our factory, located in Changsha, spans 8,000 square meters and is equipped with advanced manufacturing equipment. With a monthly production capacity of 100,000 zirconia blocks, we ensure consistent supply for our global clients.

Research and Development: We have an independent R&D team dedicated to innovation and continuous product improvement.

Advanced Equipment: Incorporates top-tier international machinery for precise and efficient production.

Supply Chain Excellence: Utilizes premium raw materials, including zirconia powder from Japan’s TOSOH and China's leading supplier, ensuring top-notch quality.

Global Reach: Products are exported to over 120 countries, including Europe, the USA, and Asia.

Quick Delivery: Regular orders are shipped within 1-3 working days, with customizable options available for special requests.

Cooperation case display

10.Frequently Asked Questions about ST White Zirconia Blocks

What makes ST White Zirconia Blocks unique compared to other zirconia types?

They offer a balance of high strength and sufficient translucency, making them suitable for both functional and aesthetic dental restorations.

Can ST White Zirconia Blocks be used for full-arch restorations?

Yes, their excellent mechanical properties make them ideal for full-arch and long-span bridges.

How do ST White Zirconia Blocks perform in terms of biocompatibility?

These blocks are highly biocompatible, making them safe and reliable for long-term use in the oral cavity.

What milling tools are compatible with ST White Zirconia Blocks?

Most CAD/CAM milling systems that support zirconia milling are compatible. Ensure the use of appropriate burs to avoid chipping.

Do ST White Zirconia Blocks shrink after sintering?

Shrinkage typically occurs after sintering, but it is predictable and factored into the design process. Exact shrinkage rates depend on the block specifications.

Are ST White Zirconia Blocks suitable for anterior restorations?

While primarily designed for strength, their translucency also allows them to be used in anterior restorations when proper shading techniques are applied.

What is the sintering temperature range for ST White Zirconia Blocks?

The sintering temperature usually ranges from 1500°C to 1530°C, depending on the manufacturer's guidelines.

How long does it take to sinter ST White Zirconia Blocks?

The typical sintering cycle lasts between 7 to 10 hours, including heating, holding, and cooling phases.

Do ST White Zirconia Blocks require special handling during milling?

Yes, they should be handled with care to avoid damage, and the milling machine should be calibrated for precision.

What are the limitations of ST White Zirconia Blocks?

They may not achieve the ultra-high translucency required for specific anterior restorations without additional shading or layering.

11.Sintering curve of st white zirconia block

| ST Plus Sintering Curve | ||||

| Sintering step | Start Temperature(℃) | End Temperature(℃) | Time(Min) | Rate(℃/Min) |

| Step 1 | 20 | 300 | 70 | 4 |

| Step 2 | 300 | 1000 | 175 | 4 |

| Step 3 | 1000 | 1530 | 177 | 3 |

| Step 4 | 1530 | 1530 | 120 | 0 |

| Step 5 | 1530 | 800 | 146 | -5 |

| Step 6 | 800 | natural cooling 20 | / | / |

12.st white zirconia block packaging

HONCHON's white zirconia blocks series

.jpg)