1. Product Basic Information

Name:

UT White Dental Zirconia Block

Definition:

The UT White Dental Zirconia Block is a high-performance dental material primarily used for fabricating full crowns, partial crowns, and bridges in dental restorations. This material is renowned for its excellent strength and aesthetic appeal, providing a natural appearance along with outstanding durability. Due to its superior biocompatibility and mechanical properties, the UT White Dental Zirconia Block has become the preferred choice among dental professionals and technicians for restorative applications.

Composition:

The chemical composition of the UT White Dental Zirconia Block primarily includes:

- Zirconium Dioxide (ZrO₂): Approximately 99% of the composition.

- Aluminum Oxide (Al₂O₃): Typically accounts for about 0.5% to 1%, enhancing the material’s toughness and strength.

- Other Oxides: May include small amounts of calcium, magnesium, and silicon to improve physical properties and sintering characteristics.

This combination of chemical components ensures that the UT White Dental Zirconia Block excels in strength, wear resistance, and aesthetics, making it suitable for various dental restoration applications.

2. Product Features

Light Translucency:

The UT White Dental Zirconia Block exhibits an impressive light translucency of 49%, significantly enhancing the aesthetic quality of dental restorations. This translucency allows for a more natural appearance, enabling the block to mimic the translucency of natural teeth. This characteristic is particularly important in anterior restorations, where aesthetic considerations are paramount, ensuring that the final restoration blends seamlessly with the surrounding dentition.

Strength:

The UT White Dental Zirconia Block boasts a bending strength of 700 MPa, making it exceptionally durable and suitable for various dental applications. This high strength allows for minimal tooth reduction during preparation, preserving more of the natural tooth structure. The robust nature of this material ensures long-lasting restorations that can withstand the forces of chewing and biting without compromising their integrity.

Compatibility:

The UT White Dental Zirconia Block is fully compatible with CAD/CAM systems, making it an ideal choice for modern dental laboratories. This compatibility facilitates precise milling and customization, allowing dental technicians to create tailored restorations that meet the specific needs of each patient. The ease of integration with CAD/CAM technology streamlines the workflow, enhancing efficiency and productivity in the dental practice.

Biocompatibility:

The UT White Dental Zirconia Block is made from biocompatible materials, ensuring that it is safe for use in the oral cavity. Its chemical composition is designed to minimize the risk of adverse reactions or allergies, making it suitable for a wide range of patients. The material's biocompatibility, combined with its aesthetic qualities and mechanical strength, positions it as a preferred choice for dental restorations.

Additional Information

- Product Type: Ultra Translucent White Zirconia

- Sintering Temperature: 1450°C

- Density: 6.0 g/cm³

3. Technical Parameters

Physical Properties:

- Density: 6.0 g/cm³

- Bending Strength: 700 MPa

- Light Translucency: 49%

- Sintering Temperature: 1450°C

These physical properties ensure that the UT White Dental Zirconia Block is not only aesthetically pleasing but also mechanically robust, making it suitable for various dental applications.

Color Options:

The UT White Dental Zirconia Block is primarily available in a white color, designed to closely match the natural shade of teeth. The ultra-translucent quality of this block enhances its ability to mimic the appearance of natural enamel, allowing for optimal aesthetics in dental restorations.

4. Applications

Recommended Indications:

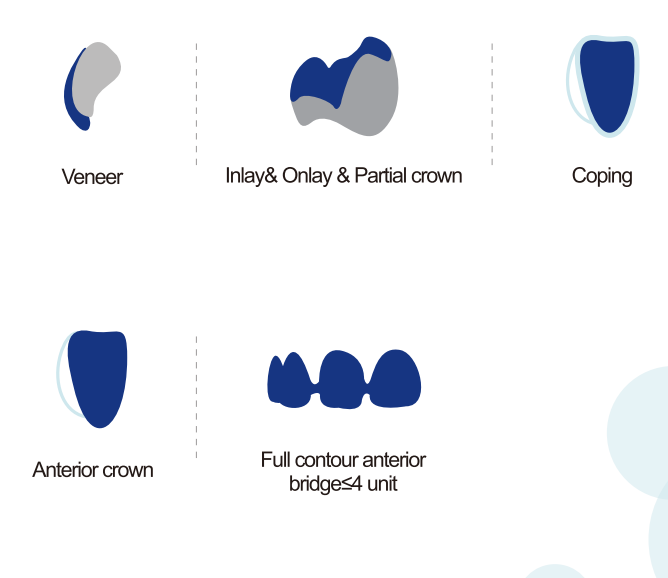

The UT White Dental Zirconia Block is versatile and suitable for a variety of dental restorations, including:

- Veneers: Ideal for enhancing the aesthetic appearance of anterior teeth while preserving the natural tooth structure.

- Inlays & Onlays: Provides strength and durability for partial restorations, ensuring a perfect fit and functionality.

- Coping: Serves as a solid foundation for crowns and bridges, enhancing the overall strength of the restoration.

- Anterior Crowns: Suitable for front teeth restorations, offering excellent aesthetics and a natural appearance.

- Full Contour Anterior Bridges (up to 4 units): Provides a seamless solution for replacing multiple anterior teeth with a natural-looking restoration.

Clinical Cases:

Numerous clinical studies and successful application cases demonstrate the efficacy of UT White Dental Zirconia Blocks in various dental procedures. For instance, restorations made with this material have shown outstanding results in terms of aesthetic integration, strength, and patient satisfaction. Dental professionals report high success rates, particularly in anterior restorations where aesthetics are critical.

5. Advantages

Aesthetic Appeal:

The UT White Dental Zirconia Block offers exceptional aesthetic benefits, providing a natural look that closely mimics the translucency and color of natural teeth. Its ultra-translucent properties allow for excellent light transmission, ensuring that restorations blend seamlessly with the surrounding dentition. This makes it an ideal choice for anterior restorations where aesthetics are paramount.

Durability:

Compared to other materials such as traditional porcelain or metal-based crowns, the UT White Zirconia Block exhibits superior durability and strength. With a bending strength of 700 MPa, it provides excellent resistance to fracture and wear. This robustness ensures that restorations made from this zirconia block can withstand the functional demands of chewing and grinding over time, leading to longer-lasting results for patients.

Ease of Use:

The UT White Dental Zirconia Block is designed with user convenience in mind. Its compatibility with CAD/CAM systems allows for precise milling and easy customization, making it simpler for dental professionals to achieve the desired shape and fit. Additionally, its consistent material properties facilitate smooth processing, reducing the likelihood of complications during fabrication. This ease of use translates into efficient workflows and shorter turnaround times for dental restorations.

6. Comparison with Competing Products

When evaluating the UT White Dental Zirconia Block, it is essential to compare it with other commonly used dental materials, such as lithium disilicate and metal crowns. Each material has its unique properties and advantages, making them suitable for different applications in restorative dentistry.

1. Strength and Durability

- UT White Zirconia Block: With a bending strength of 700 MPa, zirconia offers excellent durability and resistance to fracture. This makes it ideal for high-stress areas in the mouth, such as posterior restorations.

- Lithium Disilicate: Known for its aesthetic qualities, lithium disilicate has a lower strength than zirconia, typically around 400-500 MPa. While it is suitable for anterior restorations, it may not be the best choice for posterior applications due to its fragility under heavy occlusal forces.

- Metal Crowns: Metal crowns, particularly those made from gold or other alloys, offer exceptional strength and durability. However, they lack the aesthetic appeal of zirconia and lithium disilicate, making them less desirable for visible areas.

2. Aesthetic Qualities

- UT White Zirconia Block: The ultra-translucent nature of this zirconia block allows for excellent light transmission, making it aesthetically pleasing and suitable for anterior restorations. Its color stability and ability to mimic natural teeth enhance patient satisfaction.

- Lithium Disilicate: This material is often considered the gold standard for aesthetics in anterior restorations. It offers a natural appearance and excellent translucency but may compromise on durability in posterior applications.

- Metal Crowns: While metal crowns provide high strength, their metallic appearance makes them less appealing for aesthetic restorations. They are typically used in the posterior region, where strength is prioritized over appearance.

3. Ease of Use and Adaptability

- UT White Zirconia Block: The compatibility with CAD/CAM systems allows for precise milling and easy customization, resulting in efficient workflows for dental professionals. The predictable material properties streamline the fabrication process.

- Lithium Disilicate: Although it can also be milled using CAD/CAM technology, lithium disilicate is generally more delicate during handling and may require more careful processing to avoid chipping.

- Metal Crowns: These crowns are typically cast or milled from solid blocks of metal, making them relatively straightforward to produce. However, the lack of aesthetic flexibility and the need for additional porcelain layering for aesthetics can complicate the process.

4. Biocompatibility

- UT White Zirconia Block: Zirconia is biocompatible and well-tolerated in the oral environment, making it suitable for a wide range of patients, including those with allergies to metal.

- Lithium Disilicate: This material is also biocompatible and is commonly used in anterior restorations for its excellent aesthetic properties.

- Metal Crowns: Some patients may experience allergic reactions to specific metals, making metal crowns less desirable for certain individuals. However, they are still considered safe and effective for most patients.

7. Manufacturing Process

Manufacturing Process of UT White Dental Zirconia Block

The production of the UT White Dental Zirconia Block involves several critical steps that ensure the material's quality, strength, and biocompatibility. Below is a simplified overview of the manufacturing process:

Raw Material Selection:

- The process begins with the selection of high-purity zirconium oxide (ZrO2) powder, which serves as the primary raw material. The purity and quality of the raw materials are essential for achieving optimal properties in the final product.

Mixing and Pre-Pressing:

- The zirconium oxide powder is carefully mixed with various additives to enhance its properties. This mixture is then pre-pressed into pucks using a hydraulic press, forming the initial shape of the zirconia block.

Sintering:

- The pre-pressed pucks undergo a sintering process, where they are heated to high temperatures (around 1450°C) in a controlled environment. This step facilitates the densification of the zirconia, enhancing its strength and translucency.

Cooling:

- After sintering, the pucks are slowly cooled to room temperature. Controlled cooling is crucial to prevent cracking or warping, which can compromise the integrity of the material.

Finishing:

- The sintered blocks may undergo additional finishing processes, such as polishing or surface treatment, to enhance their aesthetic qualities and prepare them for use in dental applications.

Quality Control:

- Throughout the manufacturing process, strict quality control measures are implemented. Each batch of zirconia blocks is tested for physical properties, such as density, bending strength, and translucency. Additionally, random samples undergo biocompatibility testing to ensure they meet safety standards.

Quality Certifications

The UT White Dental Zirconia Block complies with international quality standards, ensuring that it is safe and effective for dental applications. Key certifications include:

ISO 13485: This standard specifies requirements for a quality management system (QMS) for organizations involved in the design, production, installation, and servicing of medical devices. Compliance with ISO 13485 demonstrates a commitment to consistent quality and safety in the manufacturing process.

FDA Approval: The product meets the regulatory requirements set forth by the U.S. Food and Drug Administration (FDA) for medical devices. This approval indicates that the UT White Dental Zirconia Block is safe for use in dental applications and has been evaluated for effectiveness.

UT white dental zirconia block case

Design Guide for UT White Dental Zirconia Blocks

Drill Compensation--------Drill Compensation settings must be activated throughout the milling process

Glue Clearance-----------Use the corresponding glue clearance setting to control the fit of the edge area where the inner top intersects the mold.

Extra Glue Clearance--------Use the corresponding glue clearance setting to control the internal fit of the area where the inner top interacts with the mold.

Edge Line Area---------The area from the outer edge line to the inner start line.

Smooth Area Distance------It is recommended to set the distance from the edge line to the edge engagement point to 0.2mm.

Drill Radius-----------The drill radius is the size of the end of the burr.

Drill Compensation Offset---It is recommended that the distance from the edge line to the drill compensation area is at least 0.5mm.

Edge Line Offset--------It is recommended that the effective thickness of the edge line is not less than this value. Thinner edge lines will lead to higher failure rates.

OffsetAng/e#1------------Recommended offset angle no less than 65"

Extensionfset----Recommended extension offset less than 0.01mm.

Wa/hickness------------0.5mm wall thickness ensures consistent restoration quality.

Reducing thickness may cause cracks or holes.

BridgeConnectors--------Recommended anterior restorations: minimum 6mm.

Recommended posterior restorations: minimum 9mm.

.jpg)