1. What is White Zirconia Blocks?

White zirconia block is a high-performance ceramic material used for making dental restorations, such as crowns, bridges, veneers, inlays, and implant abutments. It is known for its excellent strength, stability, and natural tooth-like appearance. The block is milled in dental labs using CAD/CAM systems, then sintered at high temperatures to achieve its final hardness and translucency.

2. Advantages of White Dental Zirconia Blocks Materials

High strength: Suitable for both anterior and posterior restorations, including long-span bridges.

Natural translucency: Closer to natural teeth in shade and brightness, especially in our ST, SHT, and UT series.

Biocompatibility: Safe and well-tolerated by gum tissue.

Stable performance: Minimal shrinkage, reliable in large-scale production.

Flexible applications: From monolithic crowns to layered restorations.

3. Material of White Zirconia Blocks

All our zirconia blocks are made from premium quality Yttria-stabilized zirconium oxide (3Y, 4Y, 5Y), carefully selected for dental applications. We strictly control powder particle size, purity, and homogeneity to ensure stable quality across all batches.

| Component | Content | Function |

| ZrO₂ + HfO₂ + Y₂O₃ | ≥99% | Forms the main structure, ensuring high strength and durability. |

| Y₂O₃ | 4.5% – 6.0% | Acts as a stabilizer to improve toughness and crack resistance. |

| Al₂O₃ | <0.15% | Enhances sintering behavior and mechanical properties. |

| Other oxides | <0.15% | Maintains uniformity and quality without affecting translucency. |

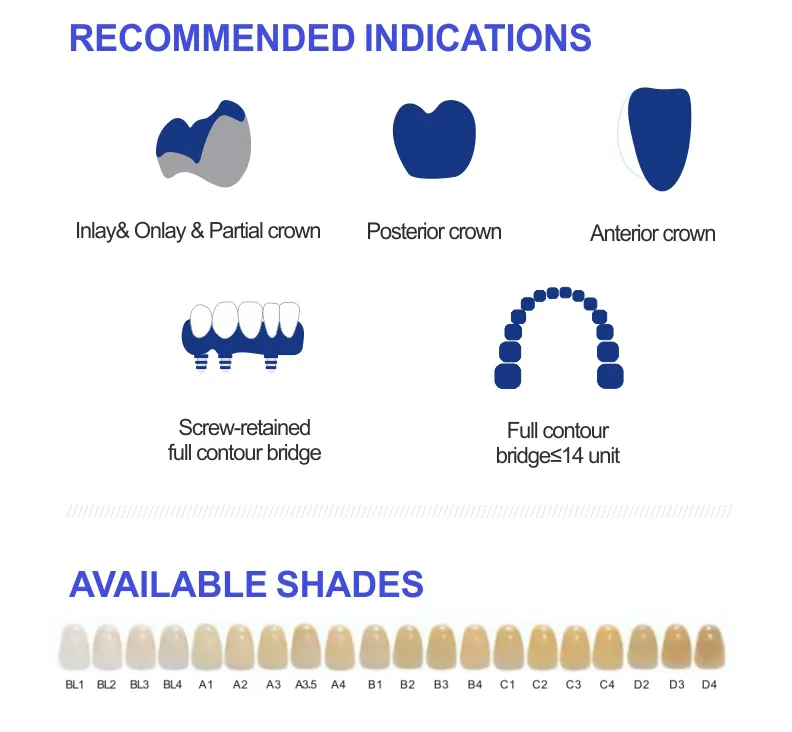

4. Application of White Zirconia Blocks

Our blocks are suitable for:

Crowns & bridges

Veneers & inlays

Implant-supported abutments

Customized full-arch restorations

Temporary and permanent dental prosthetics

We offer four series to meet different clinical needs:

HT (High Strength): Ideal for long-span bridges and posterior teeth.

ST (Super Translucent): Balances strength and esthetics, good for posterior crowns.

SHT (Super High Translucent): Best for anterior restorations with high esthetic demand.

UT (Ultra Translucent): Maximum translucency, designed for top-level esthetic cases.

5. Sintering Curve of White Zirconia Blocks

Each zirconia series has its recommended sintering curve. A typical example:

Heating rate: 8–10°C/min

Holding temperature: 1500–1550°C (depends on block type)

Holding time: 2 hours

Cooling rate: Natural cooling

We provide detailed sintering curves with every shipment for best results.

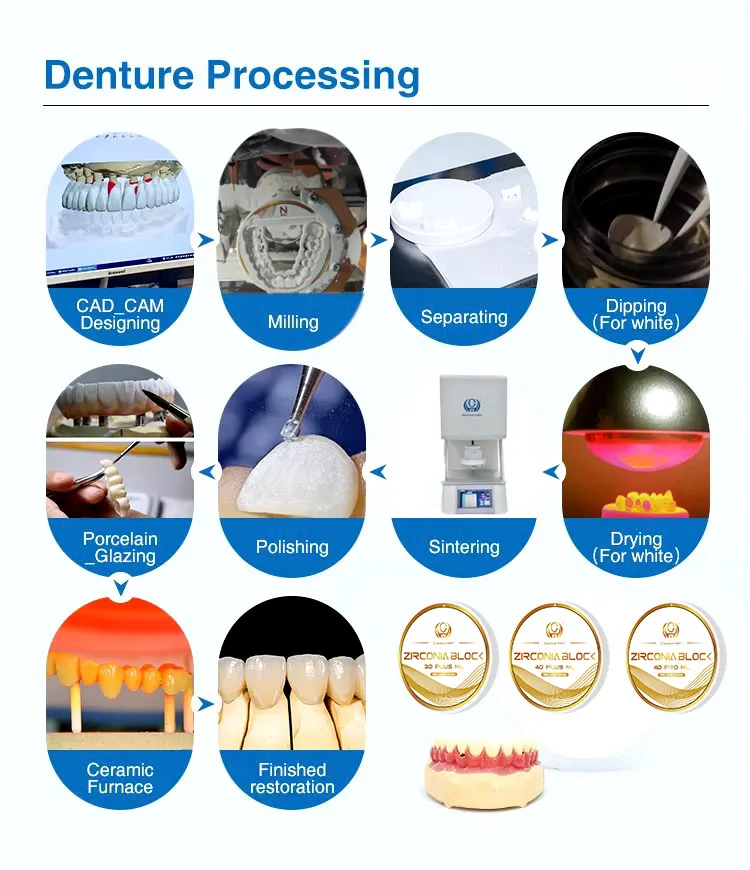

6. Process of White Zirconia Blocks

Design: Scan the impression and design restoration via CAD.

Milling: Choose the appropriate zirconia block size and type, mill with CAM machine.

Drying: Remove moisture before sintering.

Sintering: Heat treatment as per recommended curve.

Coloring (optional): Pre-shaded or dipped depending on desired effect.

Finishing: Polish, glaze or layer porcelain as needed.

7. Best Practices for Handling and Storing White Zirconia Blocks

Store in a clean, dry place to avoid moisture absorption.

Handle blocks with clean gloves to avoid contamination.

Keep away from direct sunlight and strong acids/alkalis.

Use before expiration date for best performance.

8. How to Cooperate with Us

We support OEM/ODM services and worldwide supply:

MOQ: Flexible for new partners

Free samples: Available for testing

Lead time: Usually 3–7 working days

Support: Technical guides, marketing materials, custom branding

We believe in long-term partnerships and stable supply chains.

9. Our Certifications

CE Certification

ISO 13485 Quality System

FDA Registration

RoHS and REACH Compliance

Chinese National Medical Device Certification

Each production batch undergoes strict quality inspection before leaving the factory.

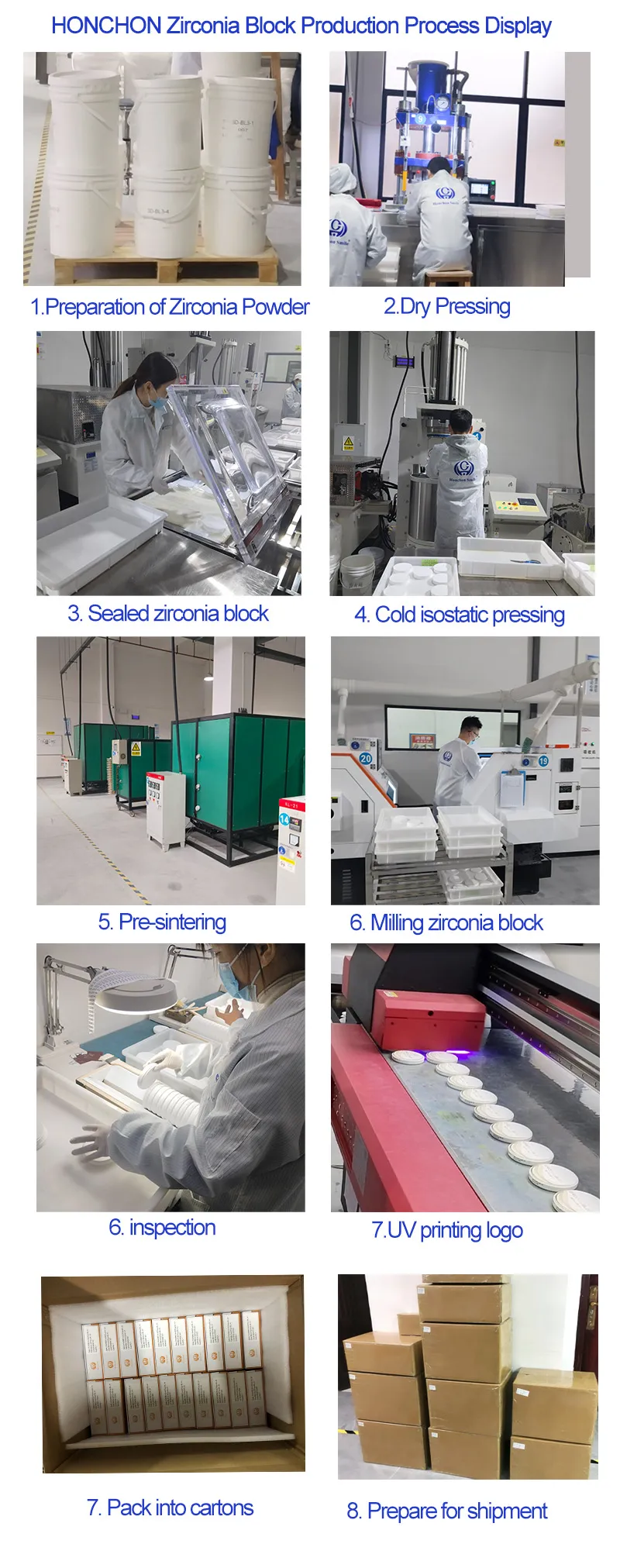

10. Our Factory

Located in Changsha, China, our factory is equipped with:

Clean room production

Precision isostatic pressing

Automated shaping & pre-sintering lines

In-house lab for quality testing

Professional R&D and support teams

We welcome partners to visit and audit the production process.

11. Frequently Asked Questions about White Zirconia Blocks

Q: Can your blocks work on open CAD/CAM systems?

A: Yes, our blocks support open systems and are compatible with VHF, Roland, Imes-Icore, Wieland, and more.

Q: Do you offer pre-shaded options?

A: Yes, all series are available in both white and pre-shaded types (A1-D4, bleach shades).

Q: How long is the shelf life?

A: 3 years under proper storage conditions.

Q: Can I customize size or packaging?

A: Absolutely. We accept customized orders for both block sizes and private label packaging.

12. White Zirconia Blocks Packaging

Each block is individually packed with:

Vacuum-sealed anti-moisture packaging

Hard paperboard box for protection

Label with product details (series, lot number, shade, size)

Optional customized outer box for OEM orders

.jpg)