CAD/CAM Dental Zirconia: Revolutionizing Dental Restorations

2025-03-13

In modern digital dentistry, CAD/CAM Dental Zirconia Block is a very commonly used restorative dental prosthesis, first of all, CAD/CAM Dental Zirconia Block has good performance in terms of aesthetics, durability, convenience, etc. Nowadays, there are many manufacturers of this material all over the world, and with the maturity of the technology, the price is becoming more and more popular. With the maturity of the technology, the price is getting cheaper and cheaper. With the maturity of the technology, the price is getting cheaper and cheaper. Gradually, it has surpassed the glass-ceramic blocks and dental metal blocks to become the first choice for denture restoration.

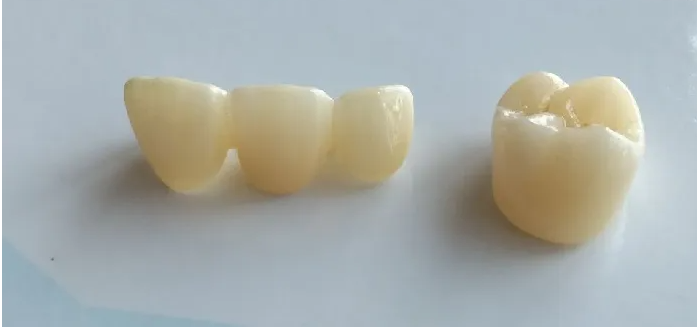

Compared to traditional dental restorative materials, zirconia denture stands out in terms of aesthetics, strength and biocompatibility. With a translucency and color gradation comparable to that of natural teeth, zirconia is able to precisely match the color of the patient's teeth, making the restorations look natural; its high flexural strength ensures long-lasting stability, even for posterior restorations subjected to strong biting forces; and as a biocompatible material, zirconium oxide does not usually cause allergies or irritation, providing patients with a more reassuring oral experience.

As a result, CAD/CAM dental zirconia blocks are now in high demand, and more and more Chinese companies are now joining in, bringing even more choices to customers around the world.

CAD/CAM dental zirconia block is a pre-formed block of zirconium dioxide material designed for computer-aided design and manufacturing techniques for the fabrication of high-precision, high-strength dental restorations (e.g., crowns, bridges, etc.). Its core characteristics are listed below:

Material Characteristics

The main component is medical grade zirconium dioxide, which has excellent mechanical properties, with a strength more than 60% higher than that of traditional alumina ceramics, strong resistance to rupture, and can support the fabrication of long bridge restorations of more than 6 units15.

The color is close to that of natural teeth, with natural edge translucency, avoiding black lines on the gums or interference in imaging examinations that may result from metal porcelain crowns.

Production process

A 3D digital model of the restoration is generated by CAD (Computer Aided Design) software, and then the restoration is precision machined from the zirconia block using CAM (Computer Aided Manufacturing) equipment (e.g. CNC cutting or 3D printing).

The whole process is digitized, replacing the traditional manual processes of mold taking and wax-up, and reducing human error.

Clinical application advantages

Chairside systems (such as CEREC) can complete the design, fabrication and wearing of restorations in a single visit, taking about 90 minutes, significantly shortening the treatment cycle.

Prices of CAD/CAM dental zirconia blocks manufactured by various brands vary (ranging from $200-$1000), and patients can choose according to their financial conditions and needs.

Technical Positioning

It is a front-end material for the digital transformation of dentistry, focusing on supporting clinicians in optimizing treatment plans through digital design, rather than relying solely on back-end processing equipment.

The material combines the precision of digital technology with the biological properties of zirconia, making it a mainstream choice for modern aesthetic restorations and functional reconstruction.

Advantages of CAD/CAM Zirconia Block

I. Good mechanical properties

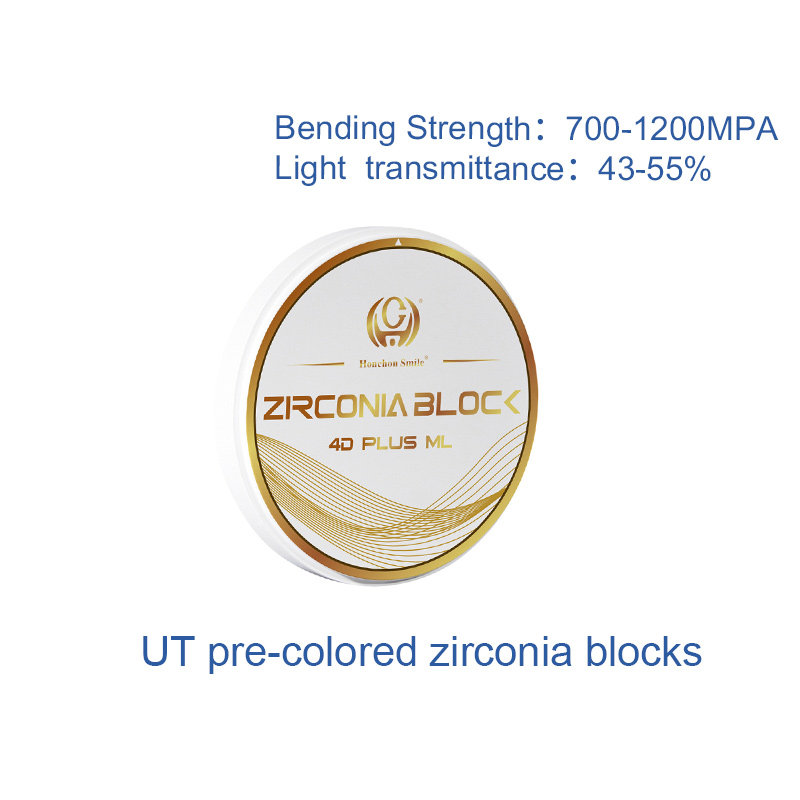

High strength and fracture resistance: zirconia has a bending strength of 700-1200 MPa and a fracture toughness of 5-10 MPa-m¹/², which is significantly better than traditional alumina ceramics, and can support the fabrication of long bridge restorations of more than 6 units.

Excellent abrasion resistance: it can still keep the form stable after long-term use, especially suitable for high occlusal force scenarios in the posterior region.

II. Natural and realistic aesthetic effect

Color and translucency: The color can be individually adjusted to match the natural tooth color, and the edge translucency is natural, avoiding the translucency problem of metal base restorations.

Ultra-thin design: Liquid 3D printing technology can produce restorations with half the thickness, while achieving better color shading and reducing the amount of tooth preparation.

III. Excellent biocompatibility

Tissue friendliness: no irritation or allergic reaction to the gums, long-term use will not cause gum staining or inflammation, and the smooth surface is not easy to adsorb plaque.

Imaging compatibility: no interference with X-ray, CT and MRI, patients can complete the examination without removing the restoration15.

Efficient and accurate digital manufacturing

Full digitalization process: CAD design of three-dimensional models, combined with CAM cutting, to achieve the edge of the restoration fit ≤ 20 μm, reducing the need for manual adjustment and grinding.

Chairside rapid restoration: design, fabrication and wearing can be completed in a single visit, taking about 90 minutes, significantly shortening the treatment cycle.

V. Wide range of clinical applications

Multi-scenario application: covering single crowns, long bridges, implant bridges and other restorations, especially suitable for all-ceramic restorations with high aesthetic requirements.

Immediate bonding performance: innovative microporous structure technology improves bonding strength by 60%-100%, ensuring immediate stabilization of the restoration.

CAD/CAM Main types of dental zirconia blocks

Full Crown

Used to make full crowns covering the entire tooth, with high strength (bending strength of 900-1200 MPa), adaptable to both anterior and posterior restorations, especially suitable for posterior areas with high biting force.

Veneers

Ultra-thin design (thickness can be as low as 0.3 mm), fabricated by CAD/CAM cutting or 3D printing, used for restoration of minor chipping or discoloration of teeth, with translucency close to that of natural tooth enamel.

Bridges and Long Bridge Types

Supporting the fabrication of long bridge restorations of 6 units or more, with excellent resistance to rupture (strength over 60% higher than aluminum oxide), it solves the limitation that traditional all-ceramic materials cannot fabricate long bridges.

Pile core type

Serves as a support structure for the tooth after root canal treatment, enhancing the strength of the remaining tooth and providing a stable abutment for subsequent full crown restorations.

Aesthetic Gradient

Adopting multi-layer structural zirconia blocks, the color transitions naturally from the neck to the incisal end of the tooth, meeting the high aesthetic needs of the anterior region.

CAD/CAM Dental Zirconia Blocks Process for Making Dentures

I. Customized teeth like “sculpted works of art”.

Traditional hand-made dentures are like sculptures made of clay - time-consuming and error-prone. CAD/CAM zirconia technology directly allows dentists to become “digital designers”:

Scanning is modeling: Using a blue light scanner (precision comparable to a microscope) to capture every detail of the teeth, a 3D digital model is generated in 5 minutes, saying goodbye to the sticky discomfort of plaster impressions.

A key to generate aesthetic teeth: the software automatically simulates the occlusal curve of natural teeth, and can also be personalized to adjust the height of the cusp, the depth of the fossa, and even add a natural gradient color to the front teeth, so that the dentures more than the real teeth “know” your smile! Secondly, from “hard core”, the dentures can be customized to fit your smile.

From “hardcore material” to “gentle fit”.

Zirconia restorations have an edge fit of ≤20 microns (1/3 thinner than a hairline), which makes the fit “seamless” and the gums are no longer afraid of harboring stains.

Dyeing technology makes dentures have their own “vitality” - young people choose amber color to show vitality, elders choose warm white color to show more youthfulness!

Zirconia blocks may look cold, but they hide a thoughtful design:

The strength of zirconia blocks is comparable to diamond: the compressive capacity of posterior restorations exceeds 1,200 MPa, so it's a piece of cake to chew nuts! A piece of cake!

Thin as a cicada also strong: veneer thickness of only 0.3mm, like to wear a layer of invisible armor to the teeth, not grinding teeth, not sensitive, but can cover ten years of coffee stains.

The color will “lie”: multi-layer gradient zirconia blocks mimic the translucent layers of natural teeth, so you can't tell it's a denture in the sunlight - even the dentist can be fooled! Even dentists can be fooled.

Patient experience: from “nightmare” to “dream”.

One visit to the clinic, immediately available: in the past, it took two weeks to wait for dentures, but now the CAD/CAM chairside system can be done in 50 minutes, and you can put on new teeth in the time it takes to drink a cup of coffee.

Farewell to “iron mouth and copper teeth”: zirconium oxide has zero interference with nuclear magnetism, so you don't need to take off your dentures for medical checkups; the surface is as smooth as jade, so plaque can't stand up when you brush your teeth. The surface is as smooth as jade, plaque can't stand when brushing teeth.

Dentist's “Regret Pill” Function

Zero cost: CAD design is not satisfactory, 5 seconds to withdraw and start again, unlike the traditional wax pattern, a pinch will be wasted.

Remote collaboration: scanning data is transmitted to the technician's office in seconds, Beijing patients take the mold in the morning, Shanghai technicians can send out the restorations in the afternoon.

Temperature hidden in the details