Coping dental zirconia block production process

2024-02-02

The production process of dental zirconia blocks is a vital aspect of creating high-quality dental restorations. It involves several stages that require precision and care to ensure the durability and aesthetics of the final products.

Firstly, high-quality zirconia powder is obtained and precisely measured. The powder is then mixed with stabilizers and binders in a predetermined ratio to create a slurry. The slurry is then poured into molds, where it is compacted and dried.

The dried zirconia blocks are then subjected to a sintering process, which involves heating them at high temperatures for several hours. This process ensures that the blocks become compact and strong, with excellent mechanical strength and stability.

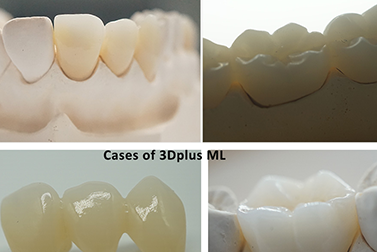

After sintering, the blocks are then cut and shaped into the desired size and shape using computer-aided milling machines. This ensures precision and accuracy in creating dental restorations.

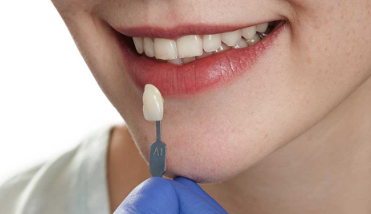

Finally, the dental zirconia blocks are polished and glazed to achieve a smooth, shiny finish. This process further enhances the aesthetic appeal of the blocks and ensures excellent biocompatibility, making them suitable for use in dental restorations.

Overall, the production process of dental zirconia blocks is a highly technical and sophisticated process that requires skill, precision, and attention to detail. However, the end results are incredibly rewarding, and the dental restorations produced from these blocks are strong, durable, and aesthetically pleasing.