Production and Characterization of Dental Zirconia Blocks

2024-04-07

Production and Characterization of Dental Zirconia Blocks

In fact, metal zirconia restorations can only absorb or reflect light, while in dental issues it shows a high degree of translucency. The dental zirconia block was introduced to address the brittleness of aluminum oxide and the consequent potential failure of implants. The mechanical properties of zirconia are such that it has the highest degree of use for any dental block. This allows for a posterior fixed partial denture and can significantly reduce the core thickness. Zirconium material is used in dentistry as a framework material, mainly made by grinding zirconia blocks, for the manufacture of posterior fixed partial dentures.

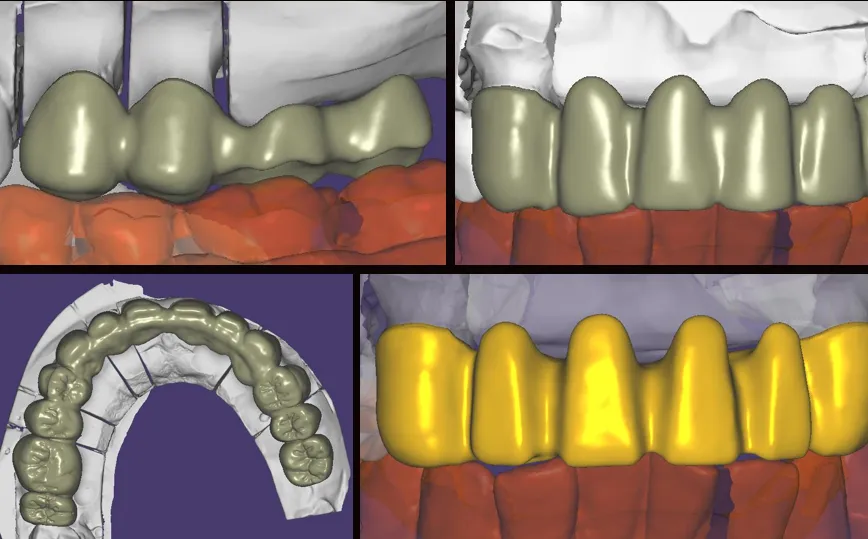

In addition to other materials, CAD/CAM systems are also used for the fabrication of the framework. The first idea of using CAD/CAM systems for the production of dental prostheses originated from dental zirconia materials. Since the last few years, there has been a trend towards using CAD/CAM systems to meet industrial quality standards, which is especially important for dental materials. Dental zirconia blocks carry frames that can be manufactured more efficiently in this way. This was followed by a significant growth in the development of other CAD/CAM laboratory systems. The white part of the zirconia does not allow for optimal aesthetic integration, so a finishing material must be used.

Computer Aided Design

1. The skill level of the designer can greatly reduce the occurrence of various engraving process problems and increase productivity.

2. Carefully designed shapes can effectively reduce grinding and dressing - increasing longevity.

3. 3. Carefully designed edge transitions can reduce the risk of engraving chipping/breakage

4. The design thickness and cost of the tooth neck edge must be as required to reduce the risk.

5. The cross-sectional area of the bridge also determines the strength of the bridge.

Liners in zirconia blocks and recently used staining solutions are common methods to compensate for the possible influence of the white color of zirconia on the final color of the restoration. The framework of crowns and bridges can be stained by infiltration techniques. However, staining by staining solutions can lead to several disadvantages. First, each brand offers different solutions which also contain different pigment types and ratios, so they can provide several different colors for the framework. In addition, each brand of dental zirconia blocks has multiple porosities, which can affect the color of the frame. Therefore, the coloring of zirconia frames is a very difficult and precise task.

The final color of the zirconia block may also vary over time due to evaporation or precipitation resulting in different pigment concentrations in the dye solution. Finally, coloring with solutions implies additional time and processes. The aim of this study was to produce self-colored dental zirconia blocks for characterization of their properties such as microhardness, fracture toughness, color difference, microstructure and phase formation.

HONCHON SMILE is a brand who specialized in selling dental lab and dentist materials on line. We provide dental zirconia blocks,there have many products like dental zirconia blocks, multilayer zirconia, dental pmma, pmma blocks, wax blocks, denta milling burs, lithium disilicate, press lithium disilicate, grinding tools and other dental restoration materials. Welcome to contact us for a free quotation.