what is Yttria Stabilized Zirconia?

2024-10-16

Yttria Stabilized Zirconia: Properties, Applications, and Market Trends

Introduction

Yttria Stabilized Zirconia (YSZ) is a highly advanced ceramic material derived from zirconium dioxide (ZrO₂), which is stabilized in its cubic crystal structure by the addition of yttrium oxide (Y₂O₃). This stabilization process ensures that YSZ maintains its cubic form at room temperature, a characteristic that enhances its mechanical and thermal properties. While yttria is the most commonly used stabilizer, other oxides such as magnesium oxide, calcium oxide, and cerium oxide can also be utilized for similar purposes. Prior to stabilization, zirconia can exist in various phases, including monoclinic, tetragonal, and cubic. However, the cubic phase achieved through yttria stabilization is particularly notable for its superior performance in various applications.

Advantages of Yttria Stabilized Zirconia

YSZ is renowned for its impressive range of properties that make it an exceptional choice for diverse applications:

High Mechanical Strength: YSZ exhibits outstanding strength, making it ideal for high-stress environments where durability is paramount. Its fracture toughness ensures reliability even under extreme conditions.

Superior High-Temperature Resistance: With a melting point exceeding 2700 °C, YSZ is well-suited for applications requiring stability at elevated temperatures, such as furnace linings and thermal barriers.

Excellent Corrosion Resistance: YSZ's inherent resistance to chemical attack, particularly from acids and bases, prolongs its lifespan in harsh environments, reducing the need for frequent replacements.

Oxidation Resistance: YSZ maintains its integrity when exposed to oxidative conditions, making it a reliable choice for protective coatings and components subjected to wear and oxidation.

Thermal Insulation Properties: YSZ serves as an effective thermal insulator, making it valuable in applications where heat retention or dissipation is critical.

Applications of Yttria Stabilized Zirconia

YSZ finds utility across various industries, including:

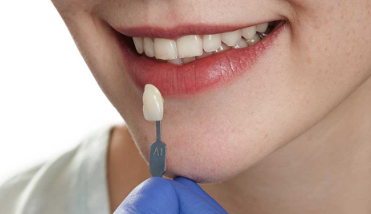

Dentistry: In the dental field, YSZ is utilized to fabricate crowns and bridges due to its impressive hardness, aesthetic qualities, and chemical inertness. It provides a natural appearance while ensuring durability and resistance to wear in the oral cavity.

Refractory Materials: YSZ's ability to withstand extreme temperatures makes it a preferred material for lining furnaces and kilns, providing excellent thermal insulation and stability.

Solid Oxide Fuel Cells (SOFC): Serving as a solid electrolyte in SOFCs, YSZ facilitates oxygen ion conduction while effectively blocking electronic conduction at high temperatures (typically between 800 and 1000 °C). This property is essential for enhancing the efficiency and performance of these energy systems.

DIY Cement: YSZ is increasingly used in DIY cement formulations, contributing to durable and heat-resistant construction materials.

Protective Coatings: The material's exceptional wear, corrosion, and oxidation resistance make it an ideal candidate for protective coatings applied to various surfaces, enhancing longevity and performance.

Other Forms of Stabilized Zirconia

In addition to YSZ, other stabilized zirconia forms include:

Magnesia Stabilized Zirconia (MSZ): Known for its remarkable temperature resistance, MSZ exhibits lower thermal conductivity and improved stability in humid environments compared to YSZ.

Calcia Stabilized Zirconia: This variant improves density, thermal shock resistance, and corrosion resistance, making it suitable for specific applications in harsh conditions.

Ceria Stabilized Zirconia: Excelling in moisture resistance, ceria-stabilized zirconia is often used in sensors and fluid control systems, where reliability and performance are critical.

Market Prospects of Yttria Stabilized Zirconia

The market for YSZ is experiencing significant growth, driven by rising demand across multiple sectors, including dental, automotive, and electronics. By 2030, the global YSZ market is projected to reach approximately $463.7 million, with a compound annual growth rate (CAGR) of 5.0% from 2024 to 2030. Factors contributing to this growth include an increasing emphasis on eco-friendly energy solutions, particularly in the context of solid oxide fuel cells.

Emerging Trends in the YSZ Market

Recent developments are shaping the YSZ market landscape:

Enhanced Material Performance: Ongoing research is focused on improving the thermal stability and mechanical strength of YSZ through innovative doping techniques and advanced manufacturing processes, leading to materials with even better performance characteristics.

Growing Energy Applications: The application of YSZ in solid oxide fuel cells and energy storage systems is on the rise, driven by its excellent ionic conductivity and ability to operate efficiently at high temperatures.

Advancements in Manufacturing Technologies: The evolution of manufacturing techniques is enhancing the cost-effectiveness and quality of YSZ production, broadening its application scope in various industries.

Sustainability Focus: The industry is increasingly adopting environmentally friendly manufacturing practices and focusing on enhancing the recyclability of YSZ materials, aligning with global sustainability goals.

Expansion into Emerging Markets: Regions such as Asia and Latin America are becoming vital for the growth of the YSZ market, fueled by industrial expansion and increasing demand for advanced materials.

Conclusion

Yttria Stabilized Zirconia is a versatile ceramic material characterized by unique properties that make it ideal for high-temperature, wear-resistant, and chemically inert applications. Its expanding market reflects growing demand across various sectors, with continuous advancements promising to enhance its performance and sustainability. For further information on high-quality advanced zirconia ceramic materials, please visit www.honchon.com