Lithium Disilicate in Dentistry: Strength, Aesthetics & Applications

2025-04-23

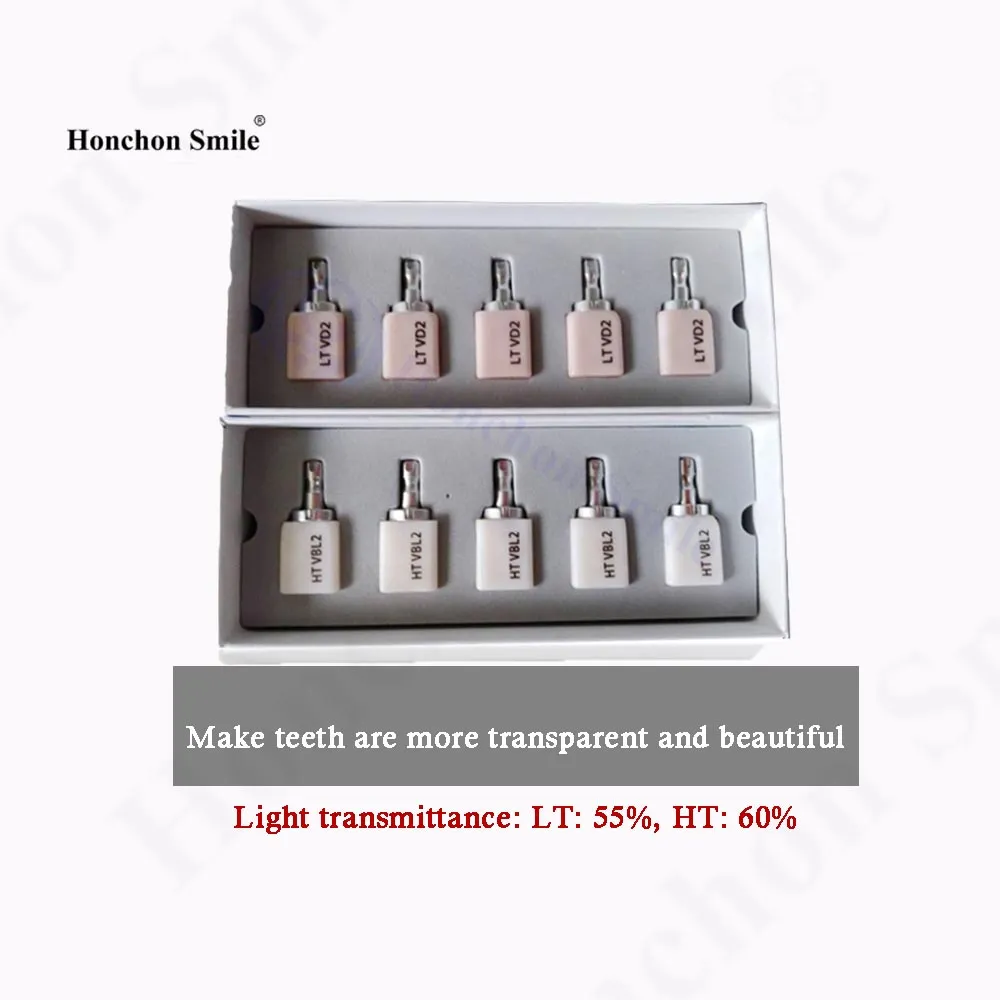

Lithium disilicate is one of the most widely used glass-ceramic materials in today’s aesthetic dentistry. Known for its natural translucency, strength, and versatility, it’s become a preferred choice for dental labs and clinics seeking both performance and beauty in restorations.

At Honchon, we offer high-quality lithium disilicate materials tailored for modern CAD/CAM systems. Whether you're a dental lab, distributor, or clinic, our materials are made to meet your needs with consistent quality and reliable supply.

What Is Lithium Disilicate?

Lithium disilicate (Li₂Si₂O₅) is a glass-ceramic material used in a variety of dental restorations. It consists of small interlocking crystals embedded in a glassy matrix, giving it both excellent strength and optical properties.

Key Material Features:

High flexural strength (~360–400 MPa)

Good fracture resistance

Adjustable translucency

Excellent bonding performance

Natural tooth-like esthetics

Common Applications in Dentistry

Lithium disilicate is ideal for a wide range of restorative treatments:

Veneers (anterior esthetics)

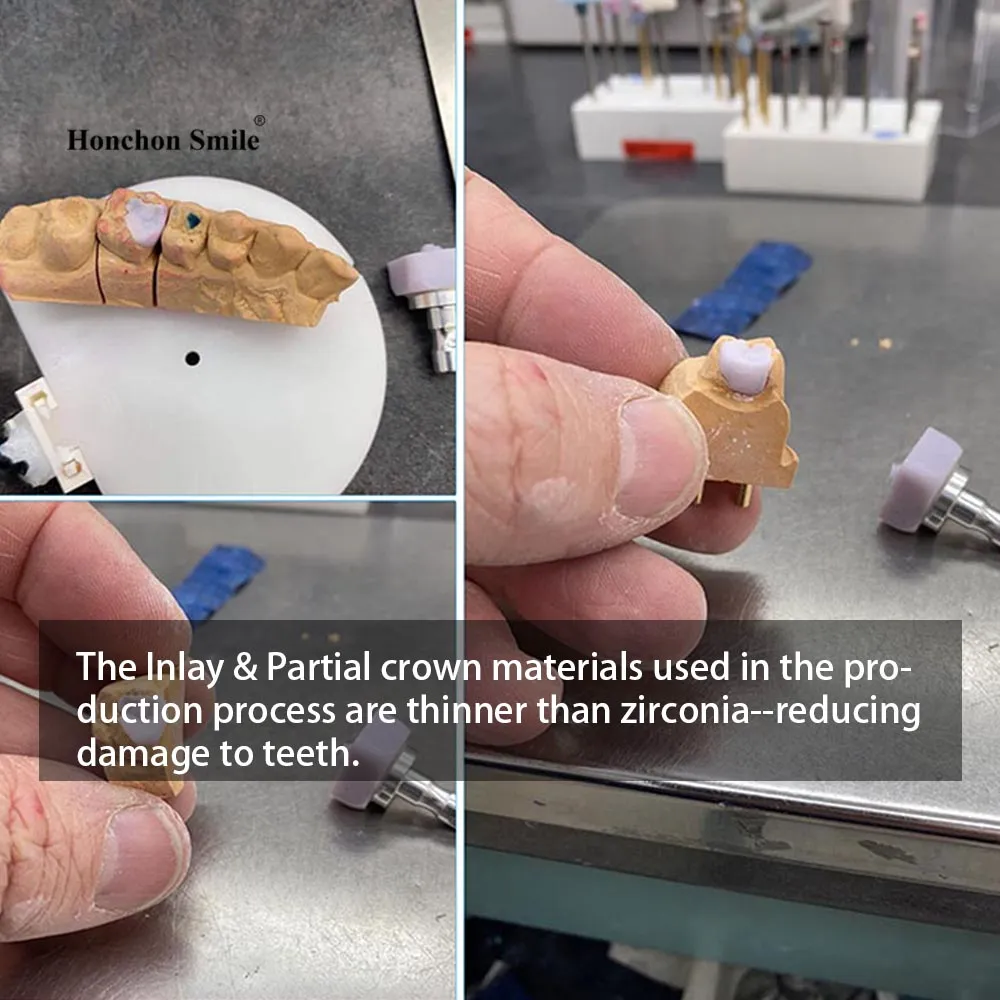

Inlays and onlays

Full-contour crowns (especially in anterior zone)

3-unit bridges (anterior)

Implant-supported crowns

Monolithic restorations (no need for veneering)

E.max vs Other Dental Ceramics

E.max is a well-known lithium disilicate brand developed by Ivoclar Vivadent. Compared to other ceramics like zirconia, lithium disilicate offers better translucency and esthetic appeal, making it more suitable for visible areas.

| Property | Lithium Disilicate (Emax) | Zirconia |

|---|---|---|

| Esthetics | Five Stars | Three Stars |

| Strength | Four Stars | Five Stars |

| Bonding Ability | Strong (acid etching) | Moderate |

| Ideal For | Anterior restorations | Posterior, bridges |

Why Choose Honchon’s Lithium Disilicate Materials?

At Honchon, we focus on quality, consistency, and customer support.

Here’s what you can expect:

Stable supply for labs and distributors

OEM and private label customization

Fast production and shipping

Responsive technical support

Certifications: ISO, CE, FDA (on request)

Whether you need standard shapes or custom shade formulations, our team is ready to support your success.

Packaging & Delivery

Clean, secure packaging to prevent moisture or contamination

Sizes and shapes tailored for your milling system

Global express delivery with real-time tracking

Let’s Work Together

We’ve been helping labs and clinics worldwide with reliable ceramic materials.

Whether you’re exploring lithium disilicate for the first time or looking for a new supplier, we’d love to hear from you.

Contact us now to get a free quote, sample, or product brochure.

Let’s build better smiles — together.

Frequently Asked Questions

Q: Can I use lithium disilicate for posterior bridges?

A: It’s ideal for anterior bridges (up to 3 units), but not recommended for high-stress posterior bridges.

Q: Do you support custom shade or shape?

A: Yes, we offer OEM and shade customization services for volume orders.

Q: What milling systems are compatible with your blocks?

A: Our materials are compatible with most open-system CAD/CAM machines.